danielhv

Well Known Member

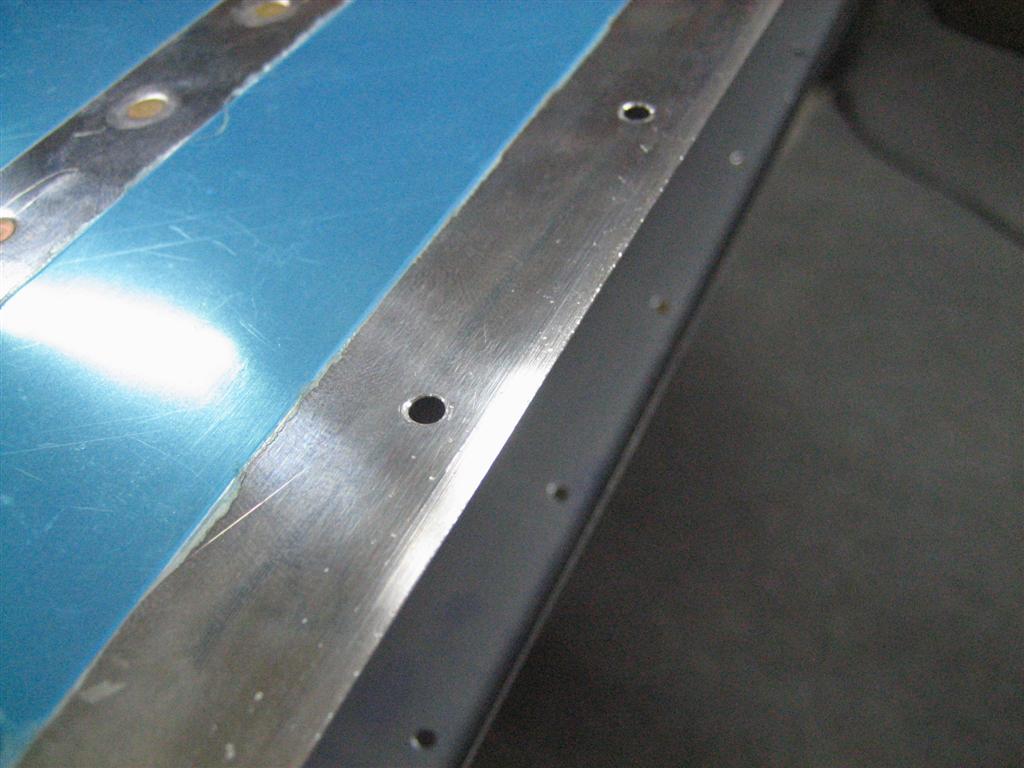

I am literally butchering my edges with this thing. I try it on scrap, not much better. I've tried keeping it loose, making it tight, pulling at different angles, holding the work in different positions, applying pressure down on the edge, etc. No matter what I do, it slips off the edge. I've even had it work its way INTO the edge leaving a nasty crease in the metal.

I flat out cannot get this thing to work right. The ONLY way I have been able to do anything with it is to manually spin the rollers... but it moves along so slow... probably 12 inches in 30 - 40 seconds. Either I'm doing something wrong or this tool is messed up.

There has GOT to be a better way to accomplish this than these vice grip tools....

Please help.

I flat out cannot get this thing to work right. The ONLY way I have been able to do anything with it is to manually spin the rollers... but it moves along so slow... probably 12 inches in 30 - 40 seconds. Either I'm doing something wrong or this tool is messed up.

There has GOT to be a better way to accomplish this than these vice grip tools....

Please help.