rmartingt

Well Known Member

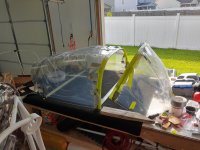

I'm on track to make the infamous Big Cut on Monday (same day my Skyview package is due to arrive!); just need to finish taping things off and get it set up. However, I'm trying to figure out what's going to be the best orientation to do it.

I've seen several build logs where the bubble is right-side up and secured with little blocks to keep it from spreading. I've also seen a few were it appears the bubble is upside-down and supported, with liberal use of duct tape to keep it together. I think I've even seen a couple where the bubble is clamped to the frame for the cut.

Anyone have suggestions here?

I've seen several build logs where the bubble is right-side up and secured with little blocks to keep it from spreading. I've also seen a few were it appears the bubble is upside-down and supported, with liberal use of duct tape to keep it together. I think I've even seen a couple where the bubble is clamped to the frame for the cut.

Anyone have suggestions here?