scsmith

Well Known Member

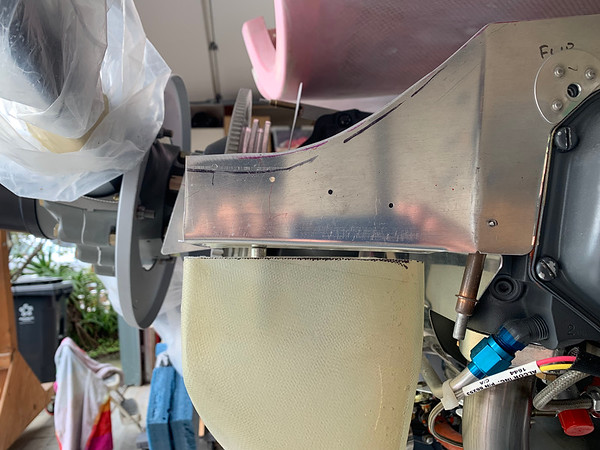

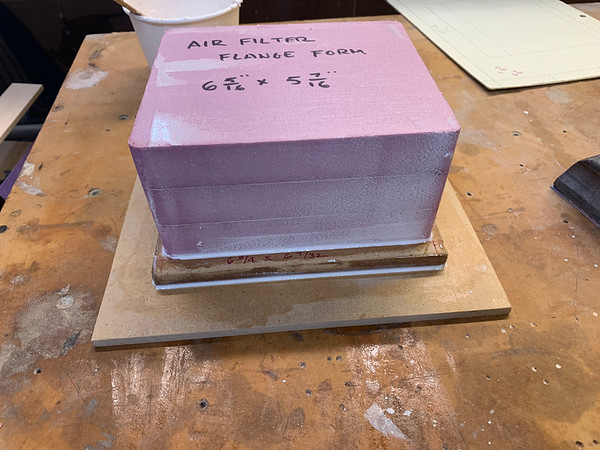

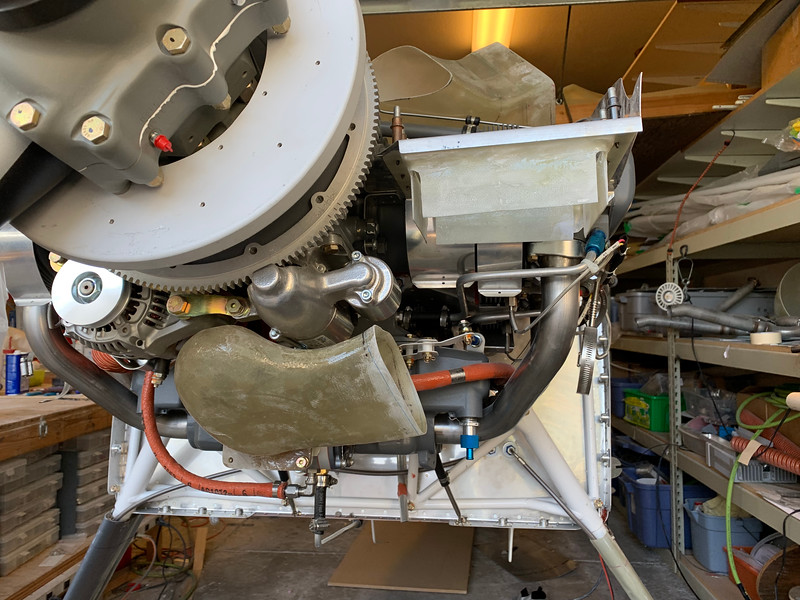

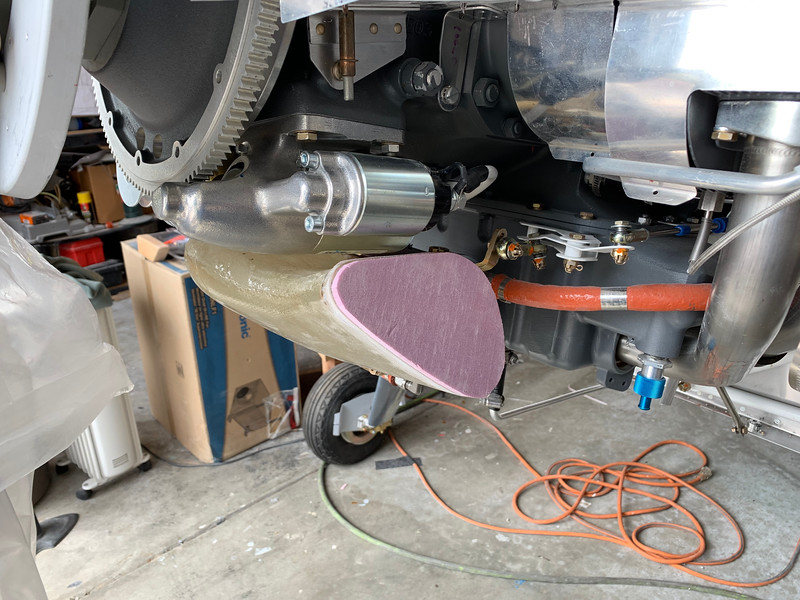

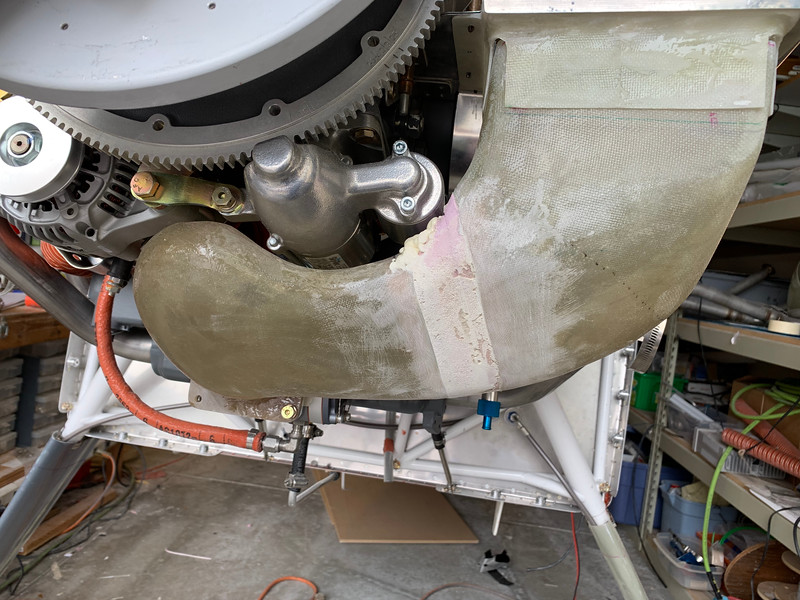

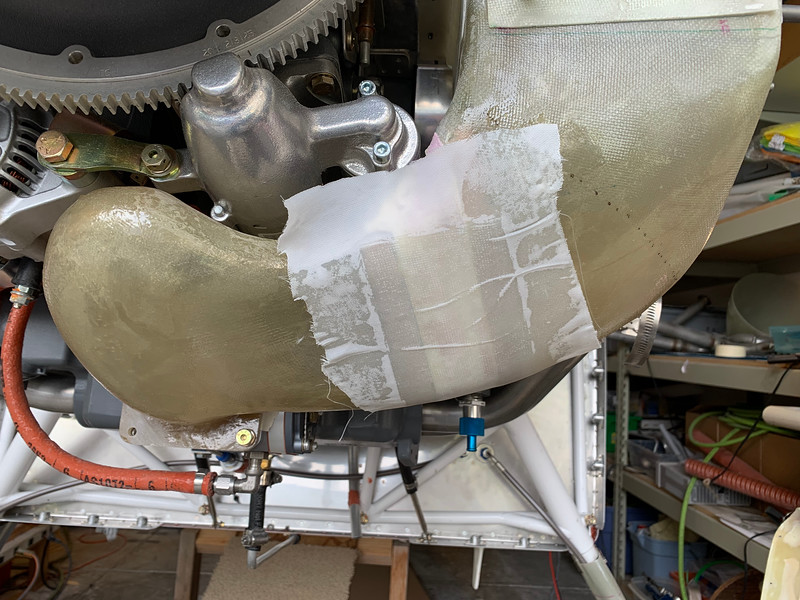

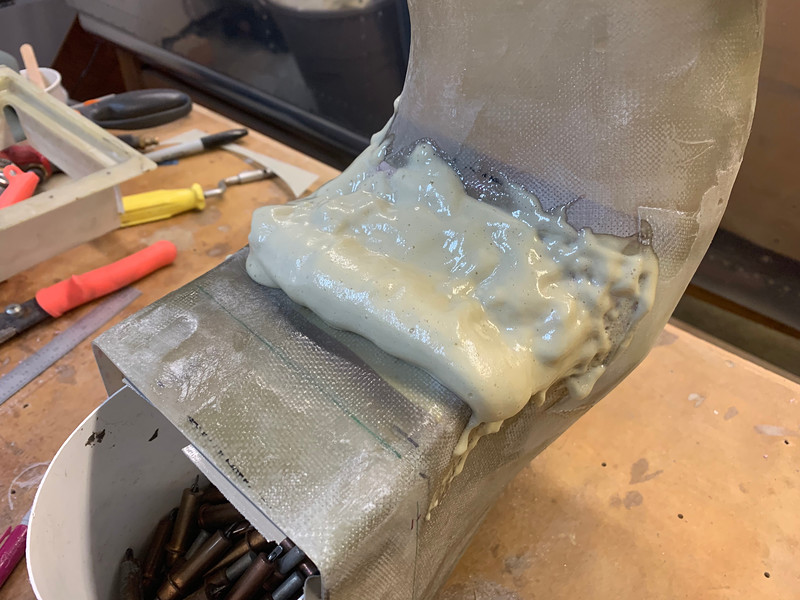

Noted, I don't disagree but lot of things require compromises when building. We will see by my empirical testing in flight. My cover installation was to tie the snorkel, baffle assembly together as a solid unit with too little real estate to fit the filter. The x gave it the strength for a thin sheet to conform to the complex shape without buckling. I agree a sharp edge will not promote laminar flow but will act as a weir causing some turbulence. The question is does that cause any effect to the engine's needed airflow. In flight the inlet is pressurized so worse case is wide open throttle at redline during initial climb out. I believe there must be substantial excess flow capacity and area since the same filter is used for the 360 and 540 with two more cylinders by Vans web site.

It is not a matter of laminar vs turbulent flow, it is a matter of reduced effective flow area because of separated flow regions.

The only way you will be able to assess performance is a side-by-side comparison of MAP at the same time and same conditions. I know that my filtered flow drops the manifold pressure about 0.3 in. Hg compared to full ram flow at sea level take-off power. I suspect yours will drop the MAP a half inch or more.