charosenz

Well Known Member

For those of you who enjoy the building part of this hobby, especially the engine side of things, I thought I would post a link to a short video I made of my "alternative" engine set up.

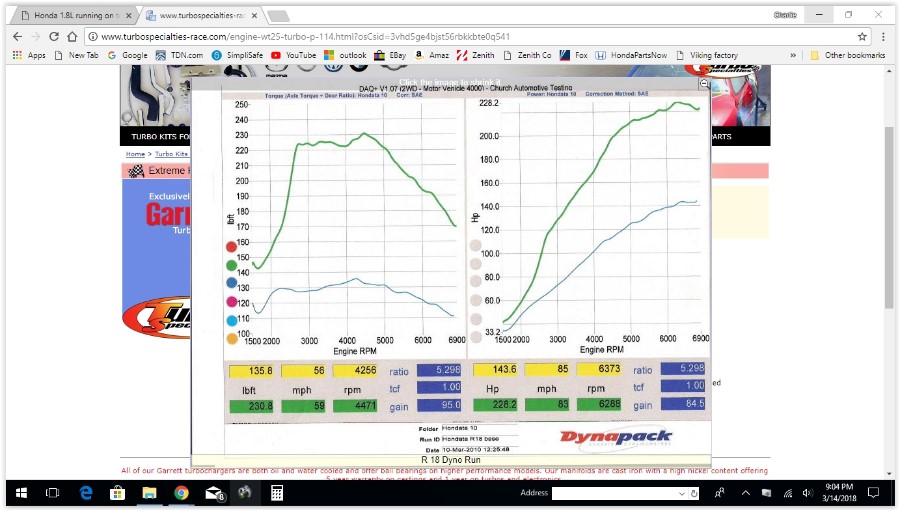

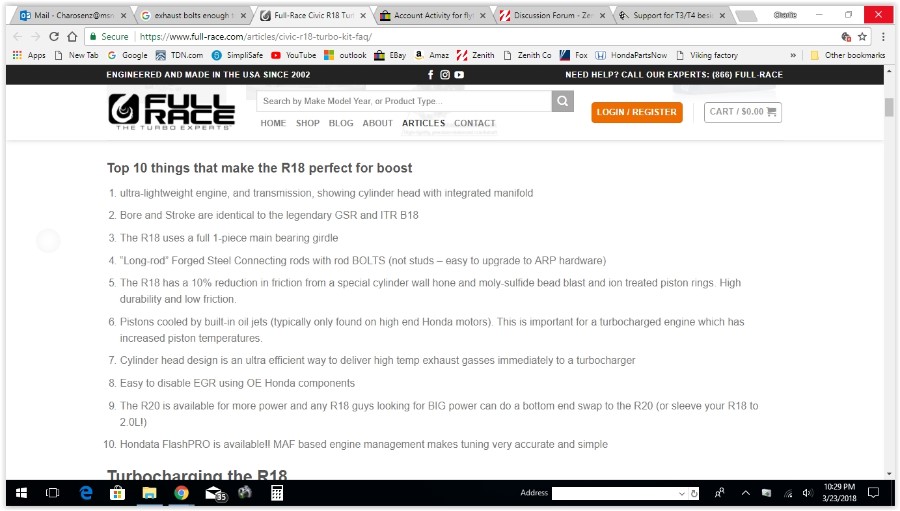

It is Honda R18 Civic engine. 1.8L. This engine is extremely common. It is in current production and has been around for 10 years in various Honda cars. It is a standard port fuel injection and COP Coil on Plug ignition. It has many advanced features like individual oil injected pistons and many other features.

I am also using the Viking Aircraft Engine PSRU (gearbox) and a 68" tapered Warp drive prop. I am very impressed with the Viking gearbox.

One of the features of this set up that I really like is the SDS EFI system. This is a fantastic engine controller. There are over 1500 planes flying with the SDS EFI system. It is a very complete, and flexible, and easy system to install. It manages your fuel injection as well as your ignition system - all easily user programmable.

https://youtu.be/7iHC4tpZxq4

I am not flying with this yet. I have an RV6a airframe done. I will need to build the engine mount and then work on the panel, and other finish work. I have a full time job so who knows when Ill be flying.

Feel free to ask questions.

Charlie Rosenzweig

Longview, Wash.

It is Honda R18 Civic engine. 1.8L. This engine is extremely common. It is in current production and has been around for 10 years in various Honda cars. It is a standard port fuel injection and COP Coil on Plug ignition. It has many advanced features like individual oil injected pistons and many other features.

I am also using the Viking Aircraft Engine PSRU (gearbox) and a 68" tapered Warp drive prop. I am very impressed with the Viking gearbox.

One of the features of this set up that I really like is the SDS EFI system. This is a fantastic engine controller. There are over 1500 planes flying with the SDS EFI system. It is a very complete, and flexible, and easy system to install. It manages your fuel injection as well as your ignition system - all easily user programmable.

https://youtu.be/7iHC4tpZxq4

I am not flying with this yet. I have an RV6a airframe done. I will need to build the engine mount and then work on the panel, and other finish work. I have a full time job so who knows when Ill be flying.

Feel free to ask questions.

Charlie Rosenzweig

Longview, Wash.

Last edited: