Geico266

Well Known Member

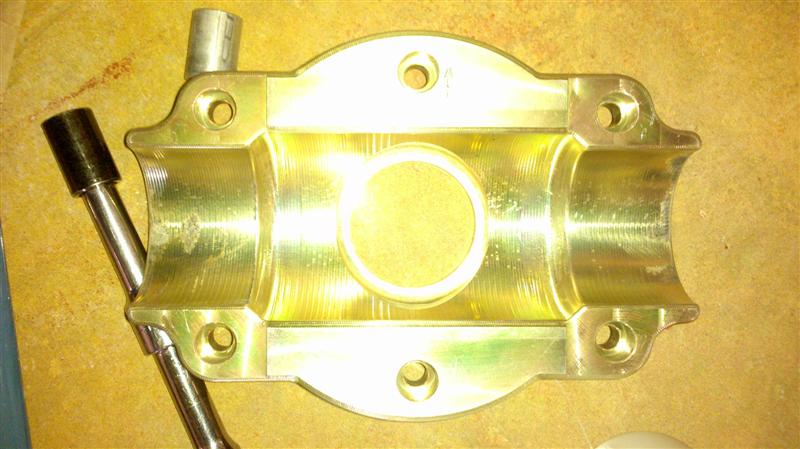

Please check the blades on your RV-12 Sensenich ground adjustable prop for play (loose blade in the hub) after the correct torque is applied to the 6 retaining bolts.

With the spinner off, grab the blade tip and gently move it "fore and aft" while at the same time with your index finger and thumb grab where the hub and the blade meet. There should be NO movement between the blade and the hub. The blade should be held securely by the hub with no movement "fore and aft" at all, according to Sensenich.

I have been helping another -12 builder put his plane togeather after painting and the FBO / painter found the prop "barrel" (the part that gets clamped on) to be loose. After talking to Sensenich we took the prop apart, inspected all parts for interference and reassembled. There was no improvement and the blade was still loose. Per Sensenich there should be NO movement at the hub, and the blade barrels should be the same size. Sensenich has been very responsive and helpful.

Please do not confuse "play" with Rotax gear box backlash. I could actually see the blade moving in the hub.

This situation probably is confined to a small number of propellers, but I thought it prudent to post it. Sensenich wanted the prop back immediately for further investigation and replacement.

The prop on my -12 has no movement.

With the spinner off, grab the blade tip and gently move it "fore and aft" while at the same time with your index finger and thumb grab where the hub and the blade meet. There should be NO movement between the blade and the hub. The blade should be held securely by the hub with no movement "fore and aft" at all, according to Sensenich.

I have been helping another -12 builder put his plane togeather after painting and the FBO / painter found the prop "barrel" (the part that gets clamped on) to be loose. After talking to Sensenich we took the prop apart, inspected all parts for interference and reassembled. There was no improvement and the blade was still loose. Per Sensenich there should be NO movement at the hub, and the blade barrels should be the same size. Sensenich has been very responsive and helpful.

Please do not confuse "play" with Rotax gear box backlash. I could actually see the blade moving in the hub.

This situation probably is confined to a small number of propellers, but I thought it prudent to post it. Sensenich wanted the prop back immediately for further investigation and replacement.

The prop on my -12 has no movement.

Last edited: