I started trying to get the cowl to fit in accordance with the plans today. Lots of on and off, sanding, on and off, sanding....

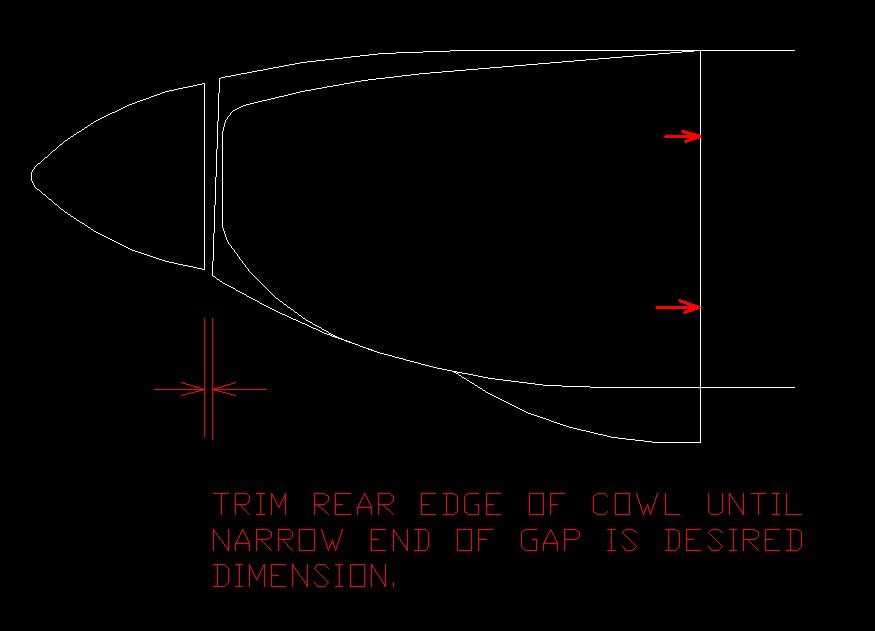

But, even with virtually no gap at the aft end of the cowl and firewall with everything centered left and right, the gap between the cowl and the spinner mount at the top (red arrow) is double the gap at the bottom (green arrow). But, the plans say this should be reversed, ie, bigger gap at the bottom so when the engine droops the gap evens out. I can't figure out why the gap is larger at the top or how to reverse the situation.

Any ideas appreciated. Oh, the spinner mount is square and flat.

But, even with virtually no gap at the aft end of the cowl and firewall with everything centered left and right, the gap between the cowl and the spinner mount at the top (red arrow) is double the gap at the bottom (green arrow). But, the plans say this should be reversed, ie, bigger gap at the bottom so when the engine droops the gap evens out. I can't figure out why the gap is larger at the top or how to reverse the situation.

Any ideas appreciated. Oh, the spinner mount is square and flat.