goatflieg

Well Known Member

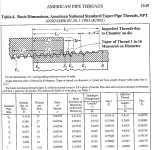

So, to tap a NPT thread, would that require a particular tap or a standard one is good to go ??

A particular tap. NPT stands for National Pipe Tapered threads. The hole and threads are slightly conical to grab the fitting as it tightens. Standard taps are straight.