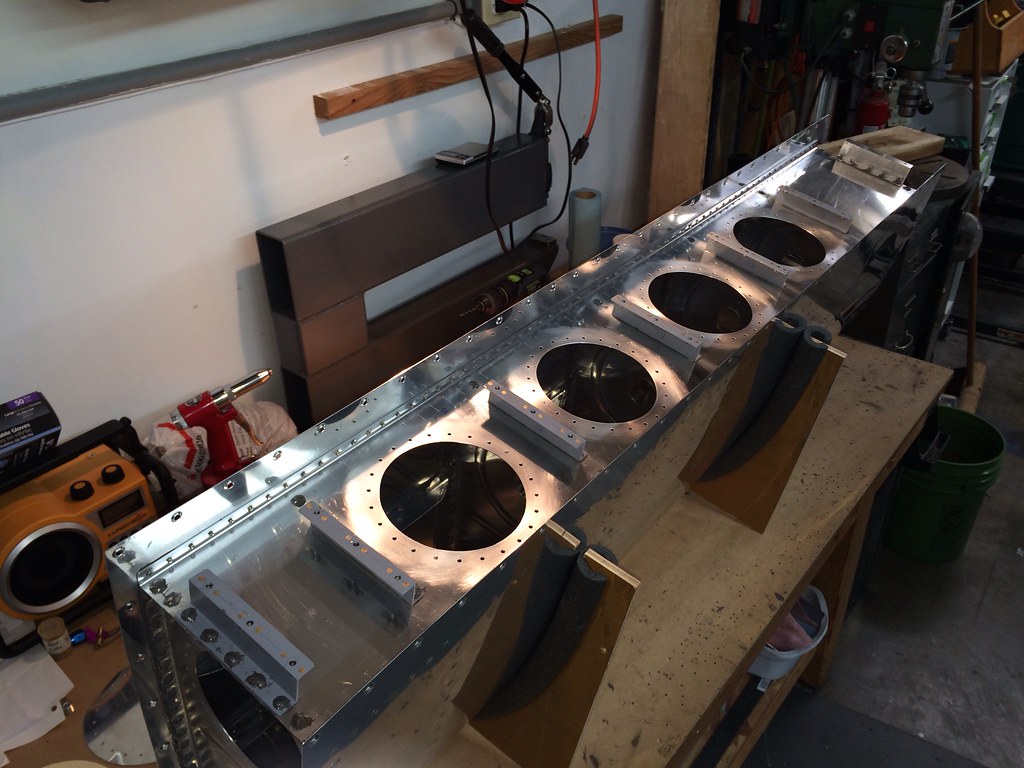

I built the tanks of my slow build RV-6 in 1999. The plane has been flying since September of 2002, and that’s about how long the top of the left fuel tank has been leaking. Just a little blue around one screw when I top the tank off to the very, very top and leave it overnight. Nothing to lose sleep over. Then about two months ago the right tank started leaking on the bottom when it had more than four gallons or so in it. ‘Head pressure leak’ one of my petrochemical engineer friends called it….

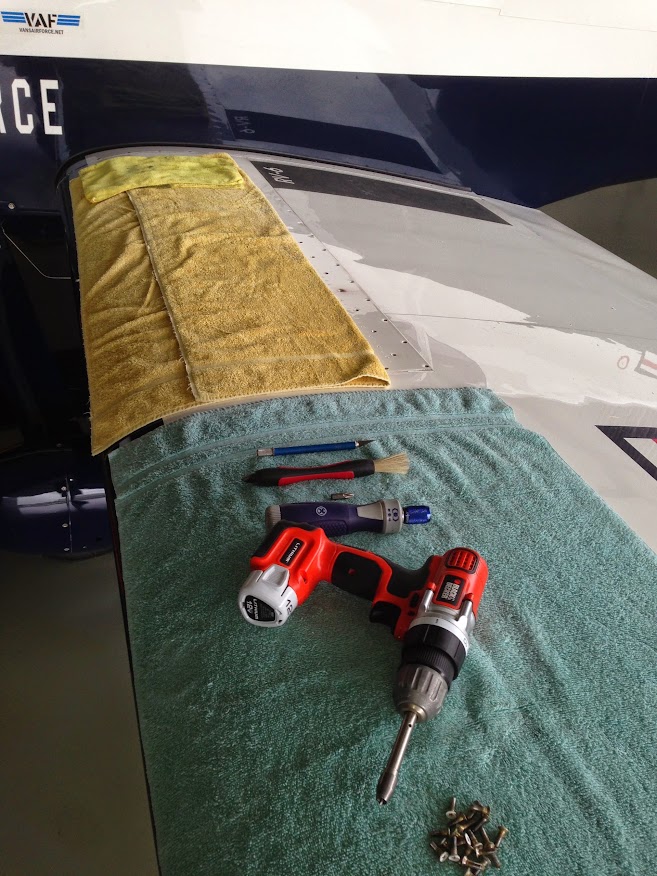

About eight years ago I bought the #8 ‘paint cutting’ bit (link) from Avery that helps you get painted-over screws out a little cleaner – the screws that hold on my tank were painted in place. Thick, way too thick, car paint. Yesterday I used the bit it for the first time.

You can’t say I rush into things <g>.

Anywho, I took some pictures with the iPhone, then uploaded them later to a folder online.

I’ll add updated pics periodically if you’re completely bored at work. Ordering ‘Tank Repair Kits’ from the mothership shortly.

v/r,

dr

Link to pics: https://picasaweb.google.com/103898861220286871615/TankRepair

About eight years ago I bought the #8 ‘paint cutting’ bit (link) from Avery that helps you get painted-over screws out a little cleaner – the screws that hold on my tank were painted in place. Thick, way too thick, car paint. Yesterday I used the bit it for the first time.

You can’t say I rush into things <g>.

Anywho, I took some pictures with the iPhone, then uploaded them later to a folder online.

I’ll add updated pics periodically if you’re completely bored at work. Ordering ‘Tank Repair Kits’ from the mothership shortly.

v/r,

dr

Link to pics: https://picasaweb.google.com/103898861220286871615/TankRepair

Last edited: