As I have indicated in my previous post regarding the Viking 110 engine, depending on the use case of the airplane and specifically the way the airplane is maneuvered (turn, bank or pitch change rate) several parts in the engine to gearbox coupling are too weak and need to be addressed.

I have not yet obtained quotes for parts since I do not yet have negotiated blueprints which have been quoted. But for the sake of giving owners something to think about we need to give some indicative numbers you could work with and consider your direction with the engine.

All costs assuming batch quantities of ~20 per run.

Stage 1: The flywheel, damper and gearbox input shaft coupling:

Here are my assumptions:

CrMo billet flywheel with thicker web and added rim mass to suppress some engine input torsional vibration: cost $250

Centraflex size 16 rubber coupling cost $120 (off the shelf) - price corrected 2/04/2023

Splined adapter made from CrMo or alternate grade steel to couple Centraflex damper to gearbox input splines Cost $250

Thus for approximately $620 you will be able to replace the weak parts with engineered parts and quit recycling inappropriate automotive spare parts for this application.

Stage 2: addressing the gearbox mount

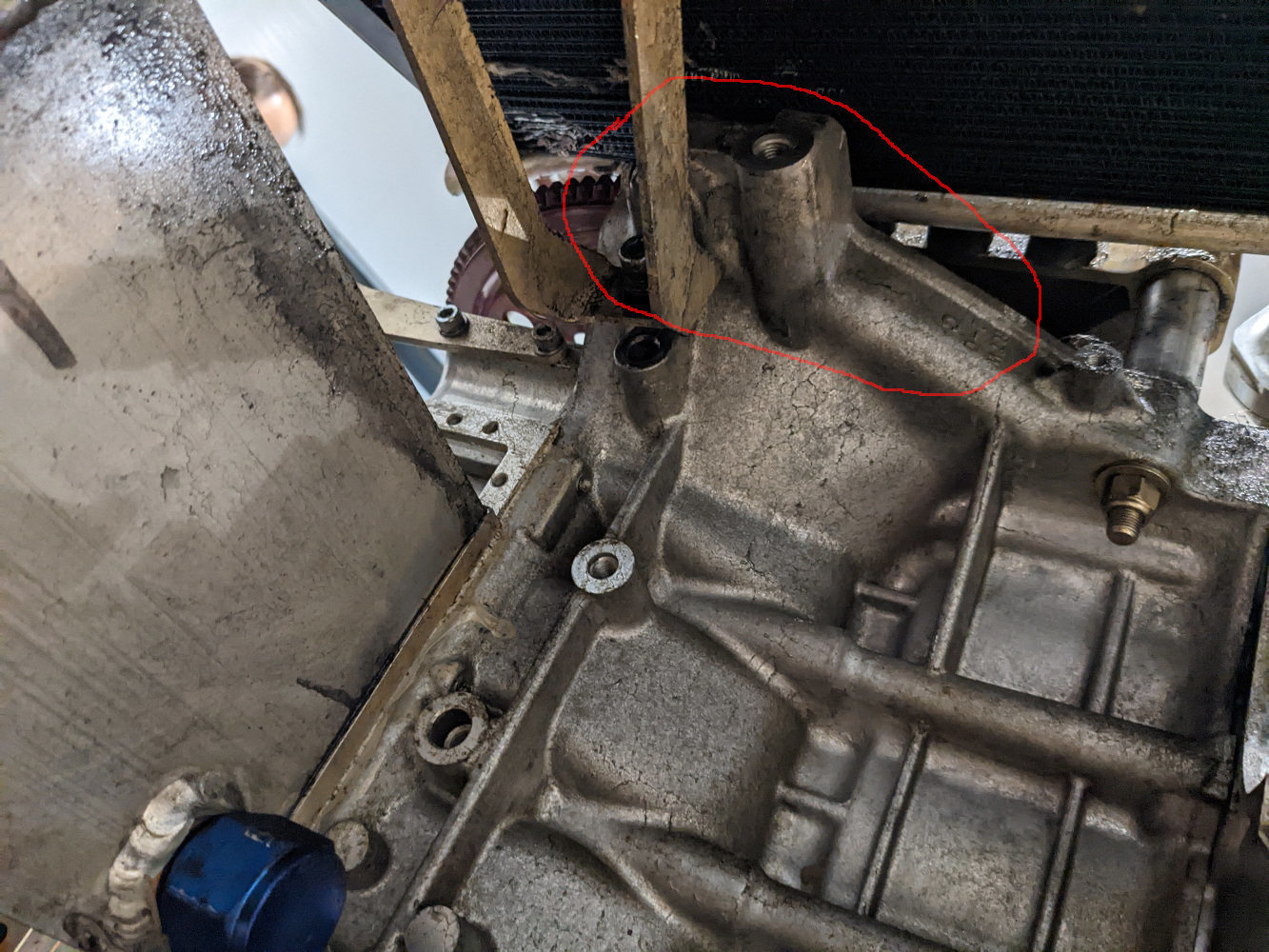

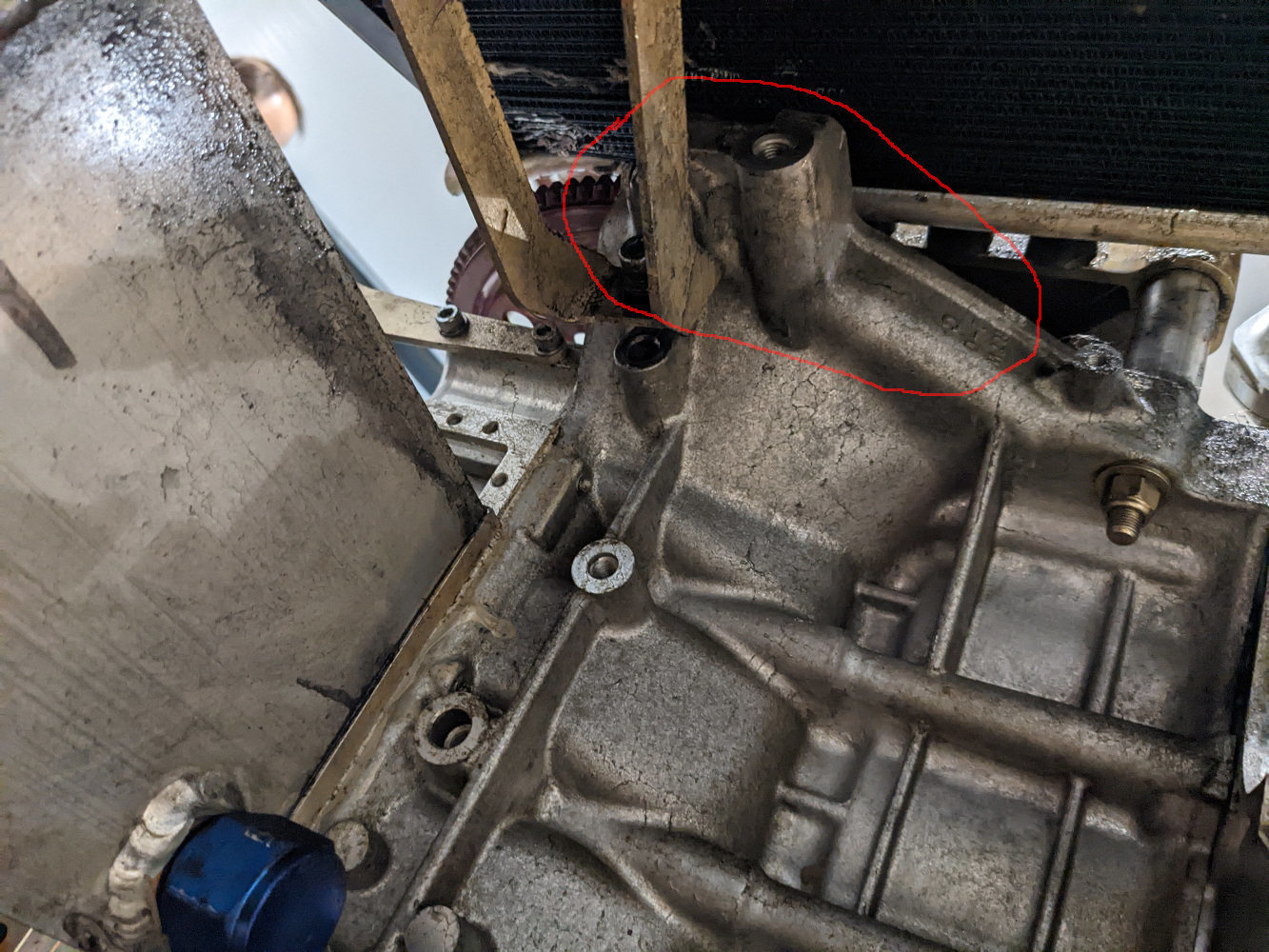

With reference to the attached image above, all Viking 110 engines had the section of the block flange casting cut off while being built. The image is of an unmodified block on which all of the Viking 110 parts have been assembled. Now the first problem that one can see is that this position for the gearbox mount falls right in the center of the radiator. The piece of the block itself is not in the way, but the support that would extend forward to the gearbox mounting plate will go through the radiator. Thus a solution for how to handle the radiator would need to be found or it would mean the tear-up of the radiator install itself and doing something different. What I am sure everyone would consider a "high effort" change.

Besides this radiator issue, the fact of course that pretty much every engine out there does not even possess that piece of the block since it was sliced off back in the Viking assembly room. I am assuming with a hand held band saw of some description since its just aluminum.

So there are 2 potential ways to address this problem. The "easy" way, is to buy a replacement engine for about $1000 and usually another $300 shipping so that you have a core with a complete block. The less easy way, is to buy just a replacement block and then prep the block for a rebuild by honing the cylinders and replacing at the very least the rings, bearings gaskets and seals. A lot more labor hours and one has to question if it would be worth it considering all the new parts one has to buy and whether the quality of the workmanship is going to be comparable to what you get with a factory assembled engine.

Then there is a 3rd possible solution but which may be subject to installation/airframe specific potential clashes.

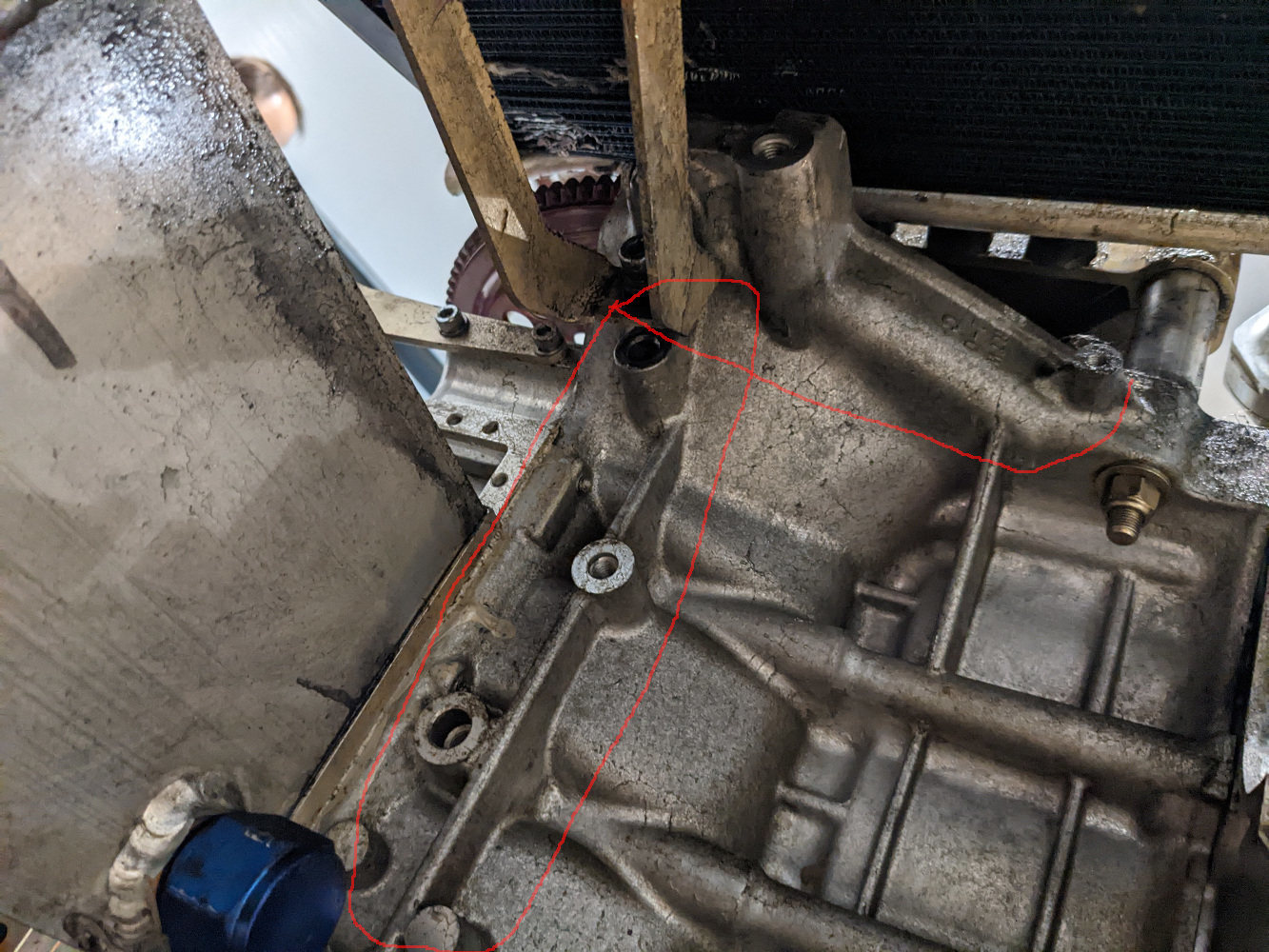

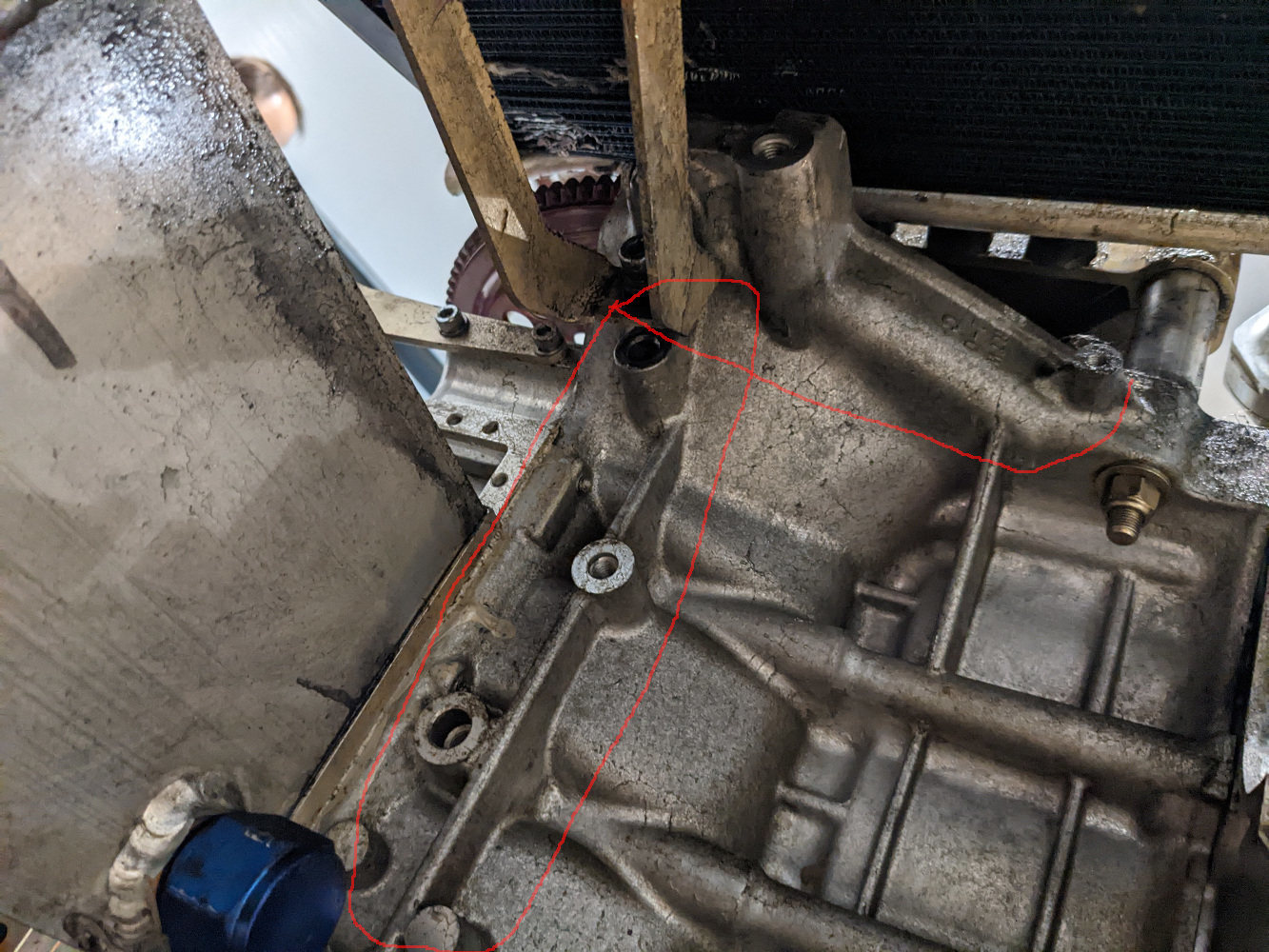

With reference to the second image above, note that there are several fastener bosses on the side of the block. One of these fastener positions is used to hold the bracket that supports the radiator. It may be possible to make a bracket that attaches to these fastener positions and creates a mounting position for the extra attachment for the gearbox. This solution would be compatible with all engines that have had the chunk of block sliced off but if during the install these fastener positions were used for some reason we would need to figure out how to resolve the conflict and allow a bracket to be installed in this position. The trick with integrating the radiator will still have to be resolved. It will likely take a custom radiator with a few rows of the core removed to make space for the support and blanking plates added to keep the air flowing through the core.

I dont yet know what the cost would be to modify a radiator, if any of you have contacts to experts in the radiator business we may be able to resolve this issue together. It would allow your engine to otherwise stay untouched and I cant see the bracket and new radiator costing more than the $1300 previously discussed for a replacement engine so you can get the missing chunk of block back.

Finally, to use the 5th attachment point, the gearbox would need to get a new back plate. It means disassembly of the gearbox, removing the cover and all the parts in it, pressing off the drive flange, then putting new bearings into the new back plate and onto the rear end of both gearbox shafts before putting it all back together. I'm sure everyone knows how Viking feels about anyone working on their gearbox, so of course your engine could no longer be called a Viking nor your gearbox.

My request is for feedback regarding the gearbox mount proposals. To accomplish any of this we would need to get together at least 20 prospective owners to allow a batch of product to be made. If we follow the 3rd path that used the side mounted bracket to stabilize the gearbox I am assuming it would be $700 for the gearbox back plate and $350 for the side mounting bracket. So combined with the phase 1 parts, one would be looking at approximately $2000 for both phases of the corrective action. If everything goes well, maybe less. Labor not included of course.

Please give me your opinions and indicate whether you would be interested in being in the first batch of 20 sets. The larger the batch, the more economical it will be because set up costs could be amortised. There will be a self funded prototype of course so that we know everything works, fits and is looking good from a torsional vibration point of view.

Thank you. If interested in being in the first batch, please send me a PM here on the forum and provide contact information.

I have not yet obtained quotes for parts since I do not yet have negotiated blueprints which have been quoted. But for the sake of giving owners something to think about we need to give some indicative numbers you could work with and consider your direction with the engine.

All costs assuming batch quantities of ~20 per run.

Stage 1: The flywheel, damper and gearbox input shaft coupling:

Here are my assumptions:

CrMo billet flywheel with thicker web and added rim mass to suppress some engine input torsional vibration: cost $250

Centraflex size 16 rubber coupling cost $120 (off the shelf) - price corrected 2/04/2023

Splined adapter made from CrMo or alternate grade steel to couple Centraflex damper to gearbox input splines Cost $250

Thus for approximately $620 you will be able to replace the weak parts with engineered parts and quit recycling inappropriate automotive spare parts for this application.

Stage 2: addressing the gearbox mount

With reference to the attached image above, all Viking 110 engines had the section of the block flange casting cut off while being built. The image is of an unmodified block on which all of the Viking 110 parts have been assembled. Now the first problem that one can see is that this position for the gearbox mount falls right in the center of the radiator. The piece of the block itself is not in the way, but the support that would extend forward to the gearbox mounting plate will go through the radiator. Thus a solution for how to handle the radiator would need to be found or it would mean the tear-up of the radiator install itself and doing something different. What I am sure everyone would consider a "high effort" change.

Besides this radiator issue, the fact of course that pretty much every engine out there does not even possess that piece of the block since it was sliced off back in the Viking assembly room. I am assuming with a hand held band saw of some description since its just aluminum.

So there are 2 potential ways to address this problem. The "easy" way, is to buy a replacement engine for about $1000 and usually another $300 shipping so that you have a core with a complete block. The less easy way, is to buy just a replacement block and then prep the block for a rebuild by honing the cylinders and replacing at the very least the rings, bearings gaskets and seals. A lot more labor hours and one has to question if it would be worth it considering all the new parts one has to buy and whether the quality of the workmanship is going to be comparable to what you get with a factory assembled engine.

Then there is a 3rd possible solution but which may be subject to installation/airframe specific potential clashes.

With reference to the second image above, note that there are several fastener bosses on the side of the block. One of these fastener positions is used to hold the bracket that supports the radiator. It may be possible to make a bracket that attaches to these fastener positions and creates a mounting position for the extra attachment for the gearbox. This solution would be compatible with all engines that have had the chunk of block sliced off but if during the install these fastener positions were used for some reason we would need to figure out how to resolve the conflict and allow a bracket to be installed in this position. The trick with integrating the radiator will still have to be resolved. It will likely take a custom radiator with a few rows of the core removed to make space for the support and blanking plates added to keep the air flowing through the core.

I dont yet know what the cost would be to modify a radiator, if any of you have contacts to experts in the radiator business we may be able to resolve this issue together. It would allow your engine to otherwise stay untouched and I cant see the bracket and new radiator costing more than the $1300 previously discussed for a replacement engine so you can get the missing chunk of block back.

Finally, to use the 5th attachment point, the gearbox would need to get a new back plate. It means disassembly of the gearbox, removing the cover and all the parts in it, pressing off the drive flange, then putting new bearings into the new back plate and onto the rear end of both gearbox shafts before putting it all back together. I'm sure everyone knows how Viking feels about anyone working on their gearbox, so of course your engine could no longer be called a Viking nor your gearbox.

My request is for feedback regarding the gearbox mount proposals. To accomplish any of this we would need to get together at least 20 prospective owners to allow a batch of product to be made. If we follow the 3rd path that used the side mounted bracket to stabilize the gearbox I am assuming it would be $700 for the gearbox back plate and $350 for the side mounting bracket. So combined with the phase 1 parts, one would be looking at approximately $2000 for both phases of the corrective action. If everything goes well, maybe less. Labor not included of course.

Please give me your opinions and indicate whether you would be interested in being in the first batch of 20 sets. The larger the batch, the more economical it will be because set up costs could be amortised. There will be a self funded prototype of course so that we know everything works, fits and is looking good from a torsional vibration point of view.

Thank you. If interested in being in the first batch, please send me a PM here on the forum and provide contact information.

Last edited: