Gary 40274

Well Known Member

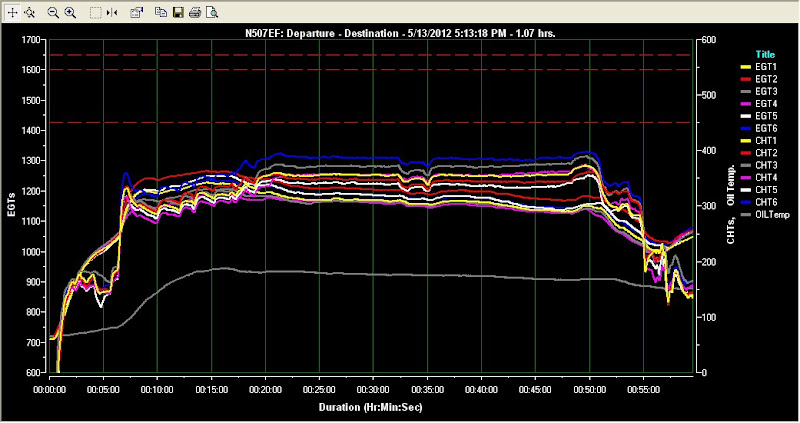

As a lot of RV10 folks do, I have high oil temps. My Cyl temps never get above 380 even on very hot days in climb. My oil however keeps climbing up until I throttle back at about 220. Many attemps have been tried, by many folks to cool the engines better, most only partially successful.

I have the 2006 oilcooler in the standard Vans setup. I decided test wether the cooler was at capacity by increasing air flow over it with a cooling fan from an ATV. The fan really blows lots of air.

My tests to date indicate no additional cooling when I turn the fan on vs when I turn it off.

Just another data point in the search for excedllance.

Gary Specketer

I have the 2006 oilcooler in the standard Vans setup. I decided test wether the cooler was at capacity by increasing air flow over it with a cooling fan from an ATV. The fan really blows lots of air.

My tests to date indicate no additional cooling when I turn the fan on vs when I turn it off.

Just another data point in the search for excedllance.

Gary Specketer