bddalm

Member

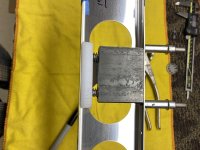

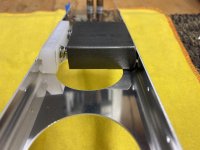

We completed the right aileron last week. Notice anything? We used solid rivets instead of the recommended pop rivets. How did we do it you ask? With this...

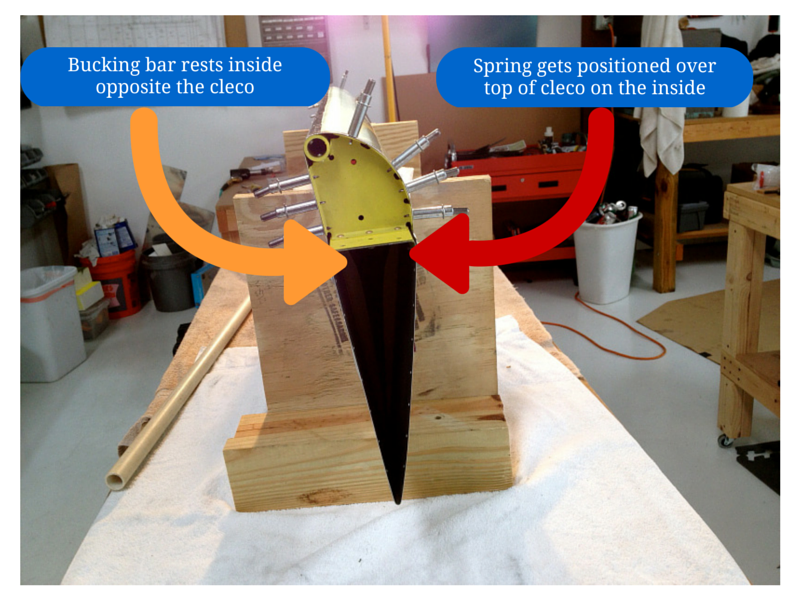

It is a spring loaded bucking bar. There is a hole at the end of the spring. You position the spring over the top of the cleco on one side of the aileron and buck the rivet on the opposite side of the aileron like so...

Next work detail = working on the right flap.