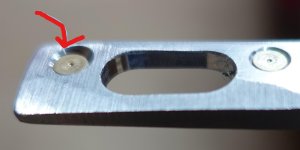

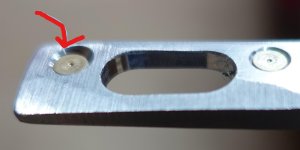

I over-countersunk the tapered hole on the RV-14 right elevator trailing edge wedge. Hole size seems fine but the dimpled test coupon slides around. I can't imagine this is a critical structural area, so tell me the quickest/simplest/cheapest way to repair this so I can move on. Possible solutions I've learned about:

1. Get a new wedge ($100 with shipping and a 1-month wait, no thanks)

2. Go up to a AD4 (there would be edge distance issues)

3. Fill with epoxy and re-countersink (I don't have any epoxy and don't know what kind to get)

Thanks!

UPDATE: See post #6 for Van's reply.

1. Get a new wedge ($100 with shipping and a 1-month wait, no thanks)

2. Go up to a AD4 (there would be edge distance issues)

3. Fill with epoxy and re-countersink (I don't have any epoxy and don't know what kind to get)

Thanks!

UPDATE: See post #6 for Van's reply.

Last edited: