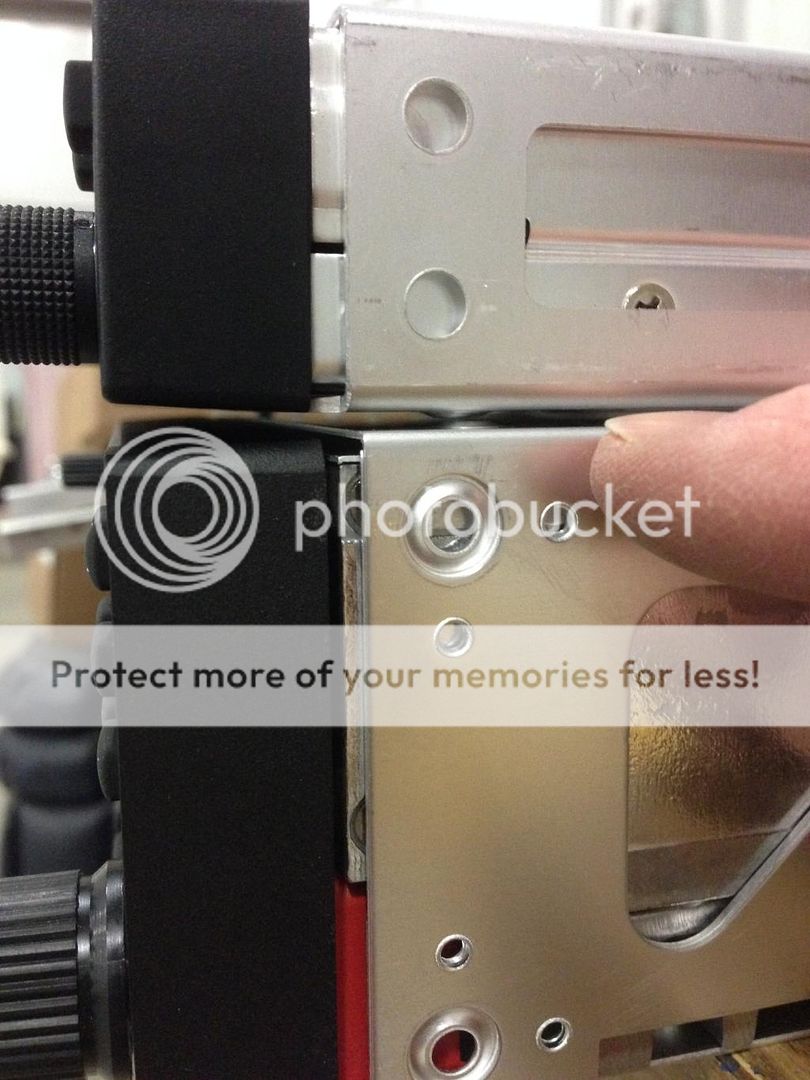

While trying to line up (the 400W bezel seems slightly taller/thicker) a GTR200 on top of a 400W, the front bumps (I'm assuming it's a spacer bump for removing/installation and cooling) interfere with each other when the bezel faces are flush. The bumps are are riding on top of each other making it hard to position the stack for securing and the gap between the 2 units looks kinda big.

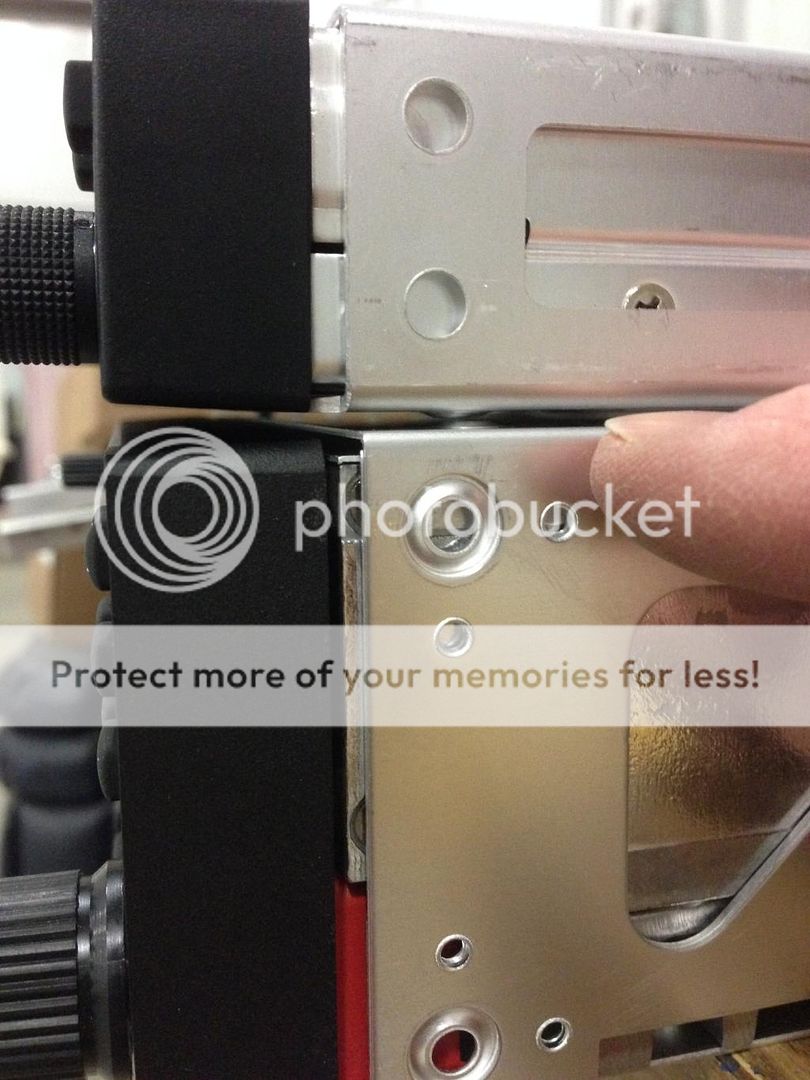

The bumps on the rear of the unit fit much nicer together.

Can I file the bumps off of one on the trays to get the racks to sit nicer and reduce the gap between them?

Am I doing something wrong?

Thanks, Andy

The bumps on the rear of the unit fit much nicer together.

Can I file the bumps off of one on the trays to get the racks to sit nicer and reduce the gap between them?

Am I doing something wrong?

Thanks, Andy