Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No throttle-prop bracket?

- Thread starter bret

- Start date

I've seen it done, but IMO the main panel real estate is rather dear. That small throttle-mixture bracket that is standard issue (slung under the center panel) has never been in my way getting in or out.

What I definitely would NOT want is one of those console-like structures extending from the panel to the fuel valve location. That WOULD be in the way.

What I definitely would NOT want is one of those console-like structures extending from the panel to the fuel valve location. That WOULD be in the way.

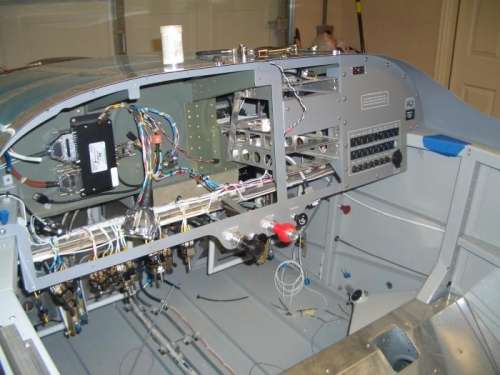

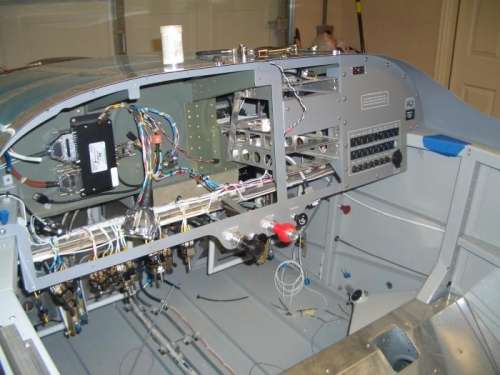

You mean like this? I tried the Vans-standard little bracket that hangs under the panel and holds the cables, to me it just looked unrefined and dinky and I didn't like it. There is plenty room to make it "look right" and work correctly, IMHO. It wasn't really an issue of making more room, but making it aesthetically pleasing.

Planecrazy232

Well Known Member

When doing a panel upgrade (which in any airplane is inevitable) as I am doing now, it sure is nice to just pull out the panel and not have to disconnect and un-install every control that is mounted in the instrument panel.

If you do a fit check in the cockpit, you will find that removing the drop down portion of the panel will have no improvement in leg room.

If you do a fit check in the cockpit, you will find that removing the drop down portion of the panel will have no improvement in leg room.

When doing a panel upgrade (which in any airplane is inevitable) as I am doing now, it sure is nice to just pull out the panel and not have to disconnect and un-install every control that is mounted in the instrument panel.

If you do a fit check in the cockpit, you will find that removing the drop down portion of the panel will have no improvement in leg room.

This is true - I just didn't like the way it looked. I will accept the extra hour of time it will cost me to disconnect and reconnect those cables in the event of a panel rebuild in order to have it look just the way I want.

Beauty is in the eye of the beholder, and all that...

I will accept the extra hour of time it will cost me to disconnect and reconnect those cables in the event of a panel rebuild in order to have it look just the way I want.

One hour?

I wish.

But yes, that is the great thing about experimental aircraft. Each builder/modifier can chose what is important to them......

loosen one bolt at throttle, two cable nuts at sump, one nut at panel and 4 screws at FW eye. I can have my throttle cable out in 5 min. if the cowl is off..........

I wasn't going to argue the point, but my experience is the same as yours.

Nor am I....

I have done it a few times

on a few different RV's

What ever work being done is times 3 different controls

And we all know that 5 minutes is a major exaggeration

I have done it a few times

on a few different RV's

What ever work being done is times 3 different controls

And we all know that 5 minutes is a major exaggeration

skylor

Well Known Member

Cable Time

Having removed and replaced cables a few times, I agree with Scott that this always takes longer than it seems like it should (granted, I have an -8 which is a little more difficult).

Don't forget that in addition to the rod-end fastener and the bracket jamb-nuts there is also the firewall feed-through to contend with. In addition, sometimes there are additional p-clamps on the cable or wires secured to them. Finally, adjusting the cable upon reinstallation always ends up being a little finicky. This is definitely not a 5 minute task!

Nor am I....

I have done it a few times

on a few different RV's

What ever work being done is times 3 different controls

And we all know that 5 minutes is a major exaggeration

Having removed and replaced cables a few times, I agree with Scott that this always takes longer than it seems like it should (granted, I have an -8 which is a little more difficult).

Don't forget that in addition to the rod-end fastener and the bracket jamb-nuts there is also the firewall feed-through to contend with. In addition, sometimes there are additional p-clamps on the cable or wires secured to them. Finally, adjusting the cable upon reinstallation always ends up being a little finicky. This is definitely not a 5 minute task!

rightrudder

Well Known Member

Personally, I like the Van's drop-down panel. But putting the controls in the main panel might lessen the chance of an errant passenger pant leg snagging on one of the knobs during ingress. To each his/her own.

flyboy1963

Well Known Member

yup, I'm a dork!!!

...yes, snag my pantleg on the throttle at least 50% of the time getting in.

I guess I need to modify my technique eh?

the drop down throttle quad is great, except in a crash, where it will hack up your legs at the knee. Good time to put some kind of rounded , soft return on the edge of the sub-panel if you are modifying things.

...yes, snag my pantleg on the throttle at least 50% of the time getting in.

I guess I need to modify my technique eh?

the drop down throttle quad is great, except in a crash, where it will hack up your legs at the knee. Good time to put some kind of rounded , soft return on the edge of the sub-panel if you are modifying things.

meloosifah

Well Known Member

I have flown in only one -7 and only one time - however, I would categorically insist that the stupid throttle bracket below the panel DOES interfere with my legs. I like to pull my feet off the pedals and definitely CANNOT do so with that bracket. When I was considering a -6 or -7 to build that bracket was definitely not on my order list. I am building an -8 now - I am not sure how any -7 builder can talk about valuable panel real estate. You guys are all spoiled with your side-by-sides!

WingsOnWheels

Well Known Member

I incorporated mine into the panel as well, but they are part of the substructure for the removable panel sections. A little bit the best of both worlds. That said, during the build it would have been nice to have the controls on a separate piece. Once complete though, it has no advantage in my setup.

bret

Well Known Member

Mount the cables in a subpanel and inset it. Drop the small panel and cables in a clump and remove the instument panel without disturbing any rigging. Maybe you can rip a cable loose in five minutes (uncowled). You ain't gonna rig one back up in five.

That's a good idea! sub panel on the panel lower portion.