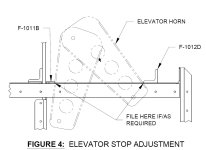

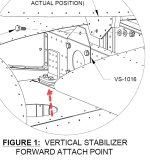

After mounting the horizontal stab on the bench as directed and installing the left and right elevators, I checked the travel and easily made the 30 degrees up and 25 degrees down with no binding or rubbing. Once I mounted the horizontal stab on the tail cone, I had an issue with the elevator stop not allowing the elevator horns from traveling back far enough to get the min 25 degrees up elevator according to what would be required to pass inspection. According to tech support, it is permissible to move the elevator stop back and even modify the aft deck. Having done that and being able to now get the required travel, I continued on and installed the pushrod. Well now the pushrod comes in contact with the the top of the hole that it travels through and prevents the elevator from traveling more than 24 degrees up. Has anyone heard of this problem before? It seems like the elevator horns are not welded correctly at the right angle.

Attachments

Last edited: