High_Flyer

Well Known Member

Hello Gents,

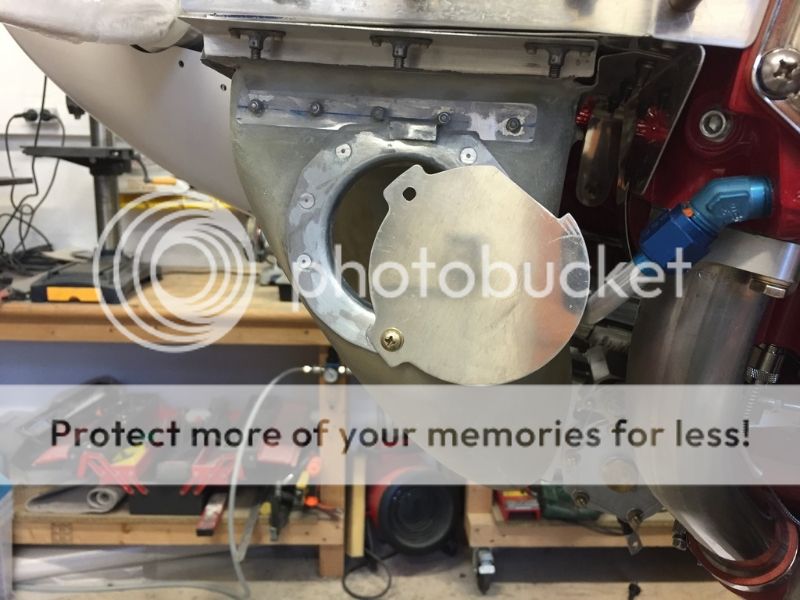

I've just modified the snorkel for my RV-7 with an IO-375 (aerosportpower) engine.

Big disapointement when I checked the alternate air : the alt air door doesn't open fully because it is restricted by the oil pipe coming from cylinder 2

Please refer to the pictures below:

Question: with the opening which is a bit less than 3/4 of an inch would this be enough for the engine to breathe properly (ie enough air to the injection intake) if I need to activate the alternate air??

Thank you.

Alain (in France)

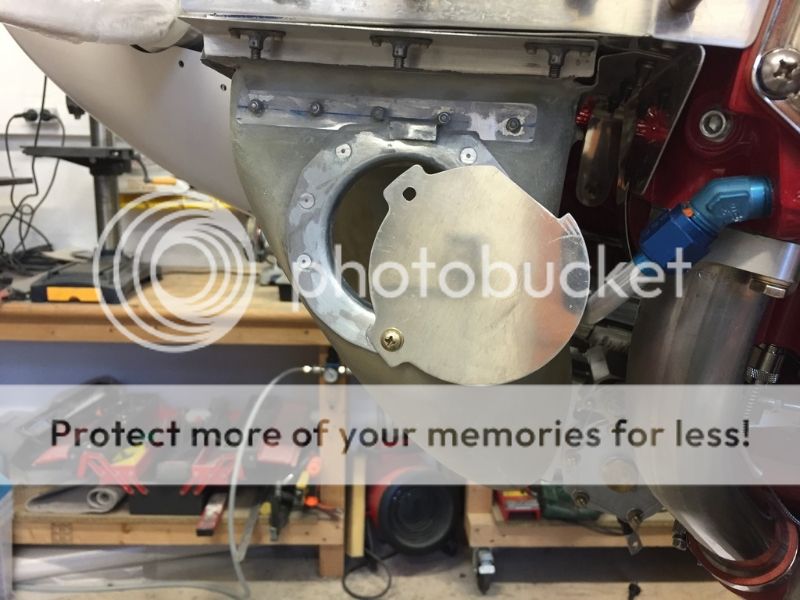

I've just modified the snorkel for my RV-7 with an IO-375 (aerosportpower) engine.

Big disapointement when I checked the alternate air : the alt air door doesn't open fully because it is restricted by the oil pipe coming from cylinder 2

Please refer to the pictures below:

Question: with the opening which is a bit less than 3/4 of an inch would this be enough for the engine to breathe properly (ie enough air to the injection intake) if I need to activate the alternate air??

Thank you.

Alain (in France)