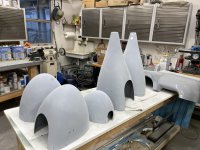

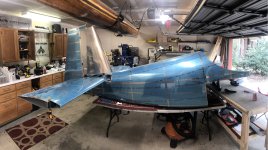

I permanently attached my wheel pant leg fairings to the wheelpants, splitting them along the separation line between the front and rear pieces. Makes it much easier to remove the wheel pants. Something to consider.

That's a great idea! Do you have photos?

Thanks,

S