Section 22: Ailerons

I could not find these plans errors on either the wiki nor the "gotcha's" excel file.

Please excuse me if i have misunderstood the plans or if they have already been identified.

I am working of the aileron plans rev 4/15/2013.

22-02

After step 3 there is an identical step 7. The intent is clear to buff out the facets in the flanges - just a typo.

22-03:

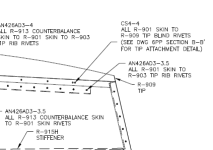

Step 1 asks you to dimple the 0.98 holes in the main ribs (these are the #40 ones). Nowhere on the page does it ask you to dimple 120 degrees the #30 holes in the rib webs (there are 6 holes which connect the upper A-1005A ribs to the lower A-1005-B ribs later on with pull rivets). These are identified to be dimpled in Figure 2 callouts. I dimpled these 100 degrees at this point because i didn't have a 120 degree dimple die.

22-05:

(at this point you have the nose skin clecod to the nose ribs and the 2 end holes of the counterbalance only. You have removed the spar, and you are about to drill the 2 mini tabs at the front of each of the nose ribs to the counterbalance).

22-05:

(at this point you have the nose skin clecod to the nose ribs and the 2 end holes of the counterbalance only. You have removed the spar, and you are about to drill the 2 mini tabs at the front of each of the nose ribs to the counterbalance).

Step 1: you drill the lower tab only - i used a 6" long #40 through the lower #30 hole in the aft rib flange (where it would connect to the spar). You then cleco the counterbalance to this rib through the hole you just drilled. You then remove the nose skin.

If you do this, you end up with 2 nose ribs held to the counterbalance with only 1 cleco and it's impossible to keep the ribs aligned.

What i did, is i clecod the nose rib to the counterbalance through the #40 hole i just drilled, then i re-installed the spar to the ribs only (not the skin).

Then i removed the nose skin. This kept the ribs in a much better alignment for the next step 2.

22-05 Figure 1 - This supports step 2; you are supposed to have the nose skin removed, but the image shows the skin still in place.

2 scenarios here: With the skin in place i could not see a way to get a drill bit in to mark the top tab hole to the counterbalance? Perhaps there is a way and in Step 1 you are not supposed to remove the nose skin (which would solve the alignment problem for the nose ribs). Not sure of the intent here. Or, you are supposed to remove the skin to get access to mark this hole, but then you have wobbly unaligned ribs. ???

Step 2: Mark the hole of the top flange etc - this works fine with the nose skin removed and the spar clecod in position as i indicated.

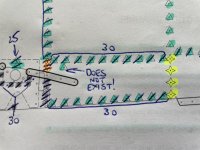

22-07:

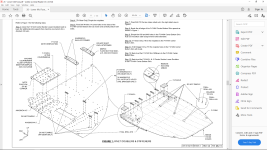

Figure 1 title is "final-drill spar and nose ribs" but there is no instruction step to do this. I assume it is not needed. Also, you are supposed to place the aileron, right side up, on the table with the nose to spar clecos hanging off the edge of the board. Then somehow cleco on the trailing edge? I am not sure how i can do this unless i have a skinny table, thinner than the chord of the aileron? (if anything can shed some light on what they are getting at, that would be great).

Another query if anyone knows, which way did people install the screws and nuts for the counterbalance? Screw heads in the tube, or on the rib flange?

Apologies if i haven't understood the plans properly or if these have already been flagged. Compared to the other plans sections, it feels like these ones are not as polished as the others - I know we are supposed to be expert builders by this stage of the build of course