TangoUniform

Member

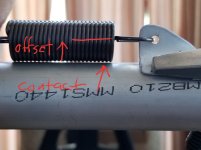

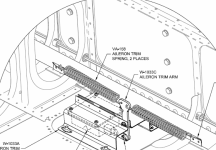

I’m attempting to install the OP-38 Aileron Trim System and am struggling with getting the two bias springs connected to both the right aileron torque tube and the trim servo operating arm. I’ve double checked the dimensions between the spring attach tabs (6” either side of the center position) and they’re correct. It requires a seemingly unreasonable amount of force to extend the springs; I seriously wonder if I’ll rip the attach taps off the torque tube. And then good luck trying to connect the second spring to the actuator arm.

Has anyone else struggled with this? Have I overlooked something? Any tips on how to get the springs connected? Any suggestions or guidance would be much appreciated.

TU

Has anyone else struggled with this? Have I overlooked something? Any tips on how to get the springs connected? Any suggestions or guidance would be much appreciated.

TU