Hi guys, I’ve been working through the fluting of the ribs and drilling of the counterweight for the flaperons. A military sheet metal guy gave me this technique that I want to share with everyone (I’ve seen many different techniques to include marking the holes and drilling on a drill press). This works well and makes clean holes without elongating the skin holes. Use a drill bushing #30, a drill bushing housing, 2.75 inch number 30 drill bit and two layers of painters tape to protect the skin. I used oil on the drill bit and also a slow speed to drill the holes. Have a few drill bits at the ready, the stainless dulls the bits fairly quickly.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flaperon Counterweight Drilling Technique

- Thread starter JMS1198

- Start date

BobbyLucas

Well Known Member

I also found that starting with a smaller drill bit, say #40, and then finishing with the #30 produced much cleaner holes in the skin. Starting with a small spotting drill might help as well as those shouldn't wander. I seem to remember I also used a spring-loaded center punch to help the bit stay in one place.

RFSchaller

Well Known Member

Here’s another tip. Start drilling with cheap Harbor Freight drill bits until you work your way up to the final size which is drilled by the expensive aircraft bit. No sense burning up expensive drill bits.

BryanStearns

Member

Housing source?

I’ll be doing my counterweights shortly, so this tip’s timely - thanks!

I’ve found a few sources for #30 slip-fit drill bushings (Yard Store, Aircraft Tool Supply), but I haven’t been able to find a housing that looks like yours — all I’ve found are the plastic egg-cup style, which looks like it has three “legs” around its round base that might not sit squarely on the curved skin. Any suggestions?

I’ll be doing my counterweights shortly, so this tip’s timely - thanks!

I’ve found a few sources for #30 slip-fit drill bushings (Yard Store, Aircraft Tool Supply), but I haven’t been able to find a housing that looks like yours — all I’ve found are the plastic egg-cup style, which looks like it has three “legs” around its round base that might not sit squarely on the curved skin. Any suggestions?

Marc Bourget

Well Known Member

For the less experienced, compared to drilling steel, the drilling stainless approach is slower drill speed with more pressure.

Stainless work hardens fast and the idea is to increase the pressure to keep cutting "under" the last pass - hopefully encountering fresh, "un-hardened" material each rotation.

My good reference, a Boeing guide, is at the office but, as always, practice on some scrap.

The drill bit you "extend" may be your own!

Stainless work hardens fast and the idea is to increase the pressure to keep cutting "under" the last pass - hopefully encountering fresh, "un-hardened" material each rotation.

My good reference, a Boeing guide, is at the office but, as always, practice on some scrap.

The drill bit you "extend" may be your own!

This is most timely as I just started drilling these today, thanks! I'm finding that drilling leaves a significant burr on the inside of the tube, unfortunately. I can file this down on the holes near the ends, but does anyone have advice for deburring the other 11 holes in the tube? I found a thread from 18 years ago (!) suggesting just shoving another tube through the pipe. Is that still the best advice?

This is most timely as I just started drilling these today, thanks! I'm finding that drilling leaves a significant burr on the inside of the tube, unfortunately. I can file this down on the holes near the ends, but does anyone have advice for deburring the other 11 holes in the tube? I found a thread from 18 years ago (!) suggesting just shoving another tube through the pipe. Is that still the best advice?

I just went through this. I attached a file (taped) to the end of a broom handle and ran it up and down the inside of the tube. No visible burrs after.

YMMV

BillL

Well Known Member

Hi guys, I’ve been working through the fluting of the ribs and drilling of the counterweight for the flaperons. A military sheet metal guy gave me this technique that I want to share with everyone (I’ve seen many different techniques to include marking the holes and drilling on a drill press). This works well and makes clean holes without elongating the skin holes. Use a drill bushing #30, a drill bushing housing, 2.75 inch number 30 drill bit and two layers of painters tape to protect the skin. I used oil on the drill bit and also a slow speed to drill the holes. Have a few drill bits at the ready, the stainless dulls the bits fairly quickly.

Joe, thanks for the tip, but on a sidebar - can you say what the brand/part number of that clever drill guide in the photo?

Thanks!!

Marc Bourget

Well Known Member

The idea behind deburring is to remove stress risers in/on ? the lower exit of the hole drilled into the tube.

Once the material gets thin enough, the drill doesn't cut any more, it tears the metal. That creates stress risers. Knocking off these torn remnants is not the same as deburring the hole.

You're better off if you achieve a chamfer on the inside of the tube.

They make deburring tools for just this purpose.

FWIW

Once the material gets thin enough, the drill doesn't cut any more, it tears the metal. That creates stress risers. Knocking off these torn remnants is not the same as deburring the hole.

You're better off if you achieve a chamfer on the inside of the tube.

They make deburring tools for just this purpose.

FWIW

Debur from the outside. This tool allows you to debur both sides of a hole from the outside, using the correct hooked blade.

https://www.cleavelandtool.com/products/3pc-aluminum-deburr-handle?_pos=7&_sid=88b985755&_ss=r

https://www.cleavelandtool.com/products/3pc-aluminum-deburr-handle?_pos=7&_sid=88b985755&_ss=r

BobbyLucas

Well Known Member

Another tool made specifically for this task: Noga Reversible Deburring Tool (mini)

https://www.amazon.com/NOGA-Reversi...noga+reversible+deburring+tool,aps,119&sr=8-2

https://www.amazon.com/NOGA-Reversi...noga+reversible+deburring+tool,aps,119&sr=8-2

RFSchaller

Well Known Member

If you don’t have the fancy tool to keep the tube from rolling you can epoxy two parallel 1X2’s on a Piece of 2X4 with a1/2” gap in between and lay the tube in the gap to keep it from rolling while drilling.

If you don’t have the fancy tool to keep the tube from rolling you can epoxy two parallel 1X2’s on a Piece of 2X4 with a1/2” gap in between and lay the tube in the gap to keep it from rolling while drilling.

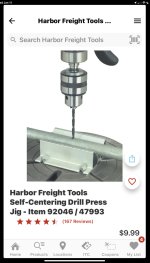

In the aviation aisle at HF…

Harbor Freight Tools Self-Centering Drill Press Jig - Item 92046 / 47993 https://hftools.com/app92046

Attachments

I’m going to save some people a couple of hours of head scratching too…when building the right flaperon, the instructions say mirror the left, however this needs some interpretation. As confirmed by DOG Aviation, who called Vans, you have to switch the position of the left and right ribs (outer to inner and vice Versa, on the A1204 and the A1210) you will know that it’s correct because the A1207R will fit properly (I devoted two hours to this last night, running in place).

In the aviation aisle at HF…

Harbor Freight Tools Self-Centering Drill Press Jig - Item 92046 / 47993 https://hftools.com/app92046

This thread is super helpful and I'm sure saved me from having to re-order parts. Thanks to all for posting tips.