RudiGreyling

Well Known Member

Hi RVators,

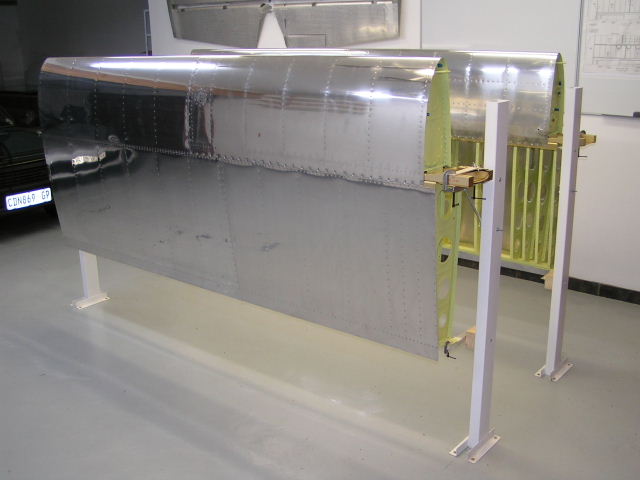

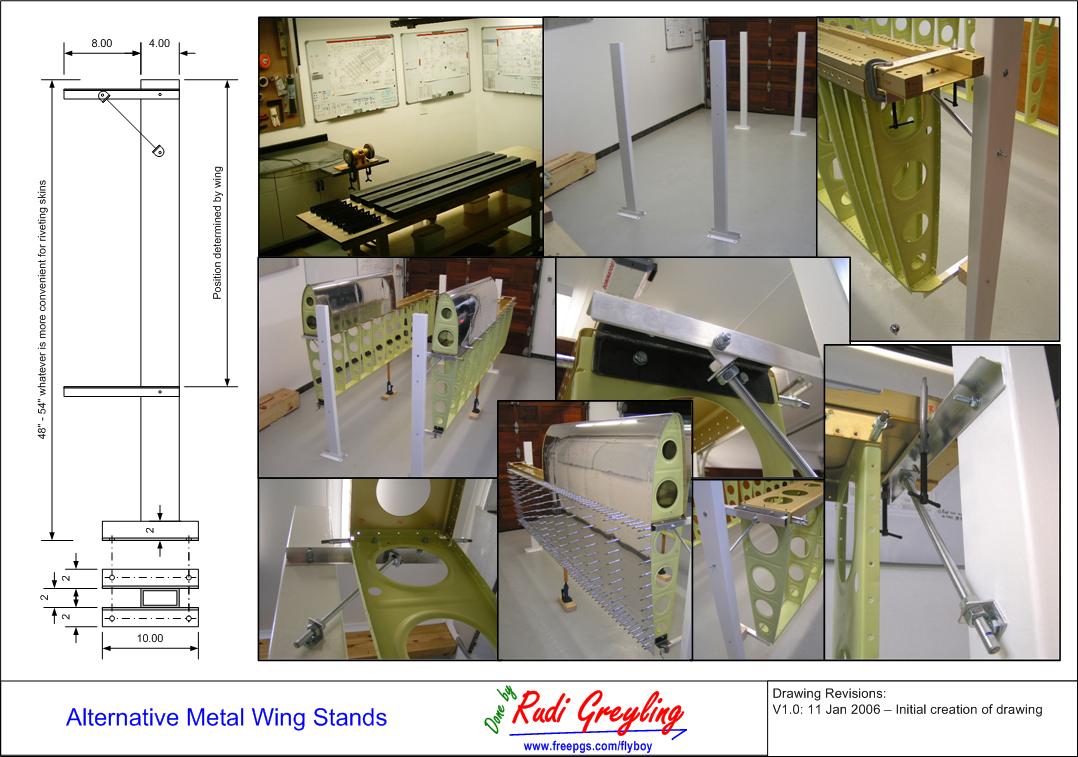

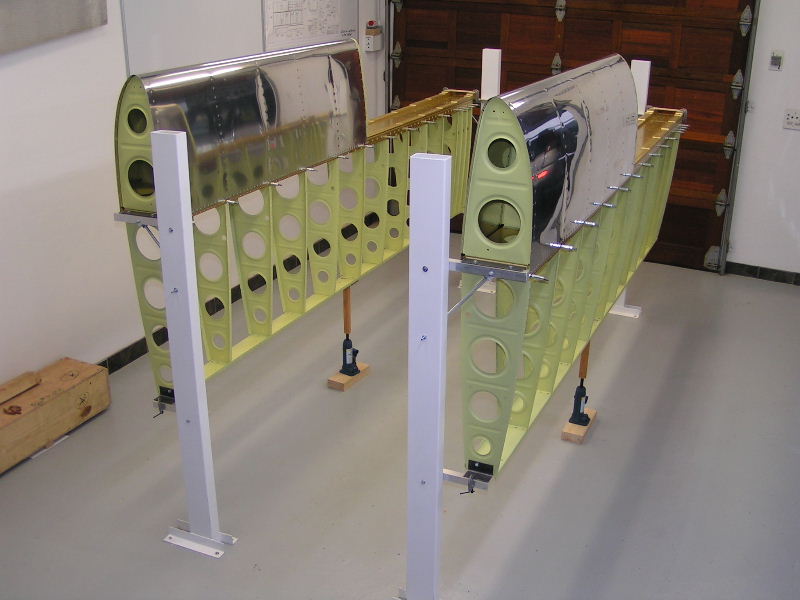

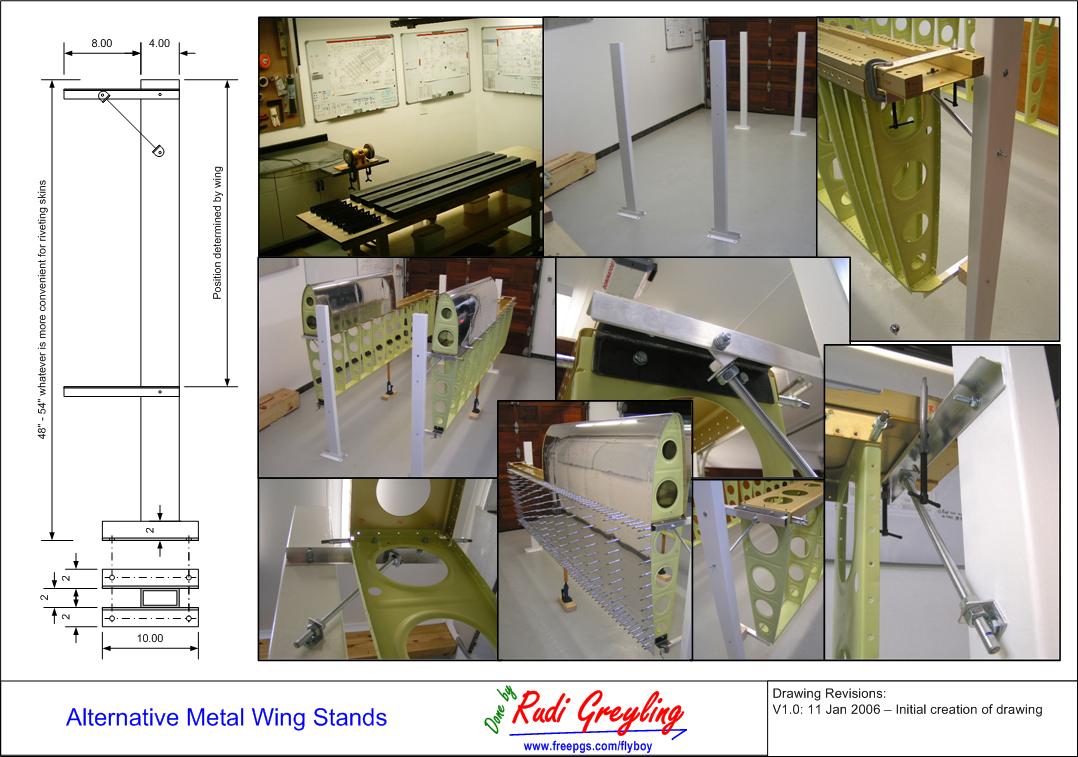

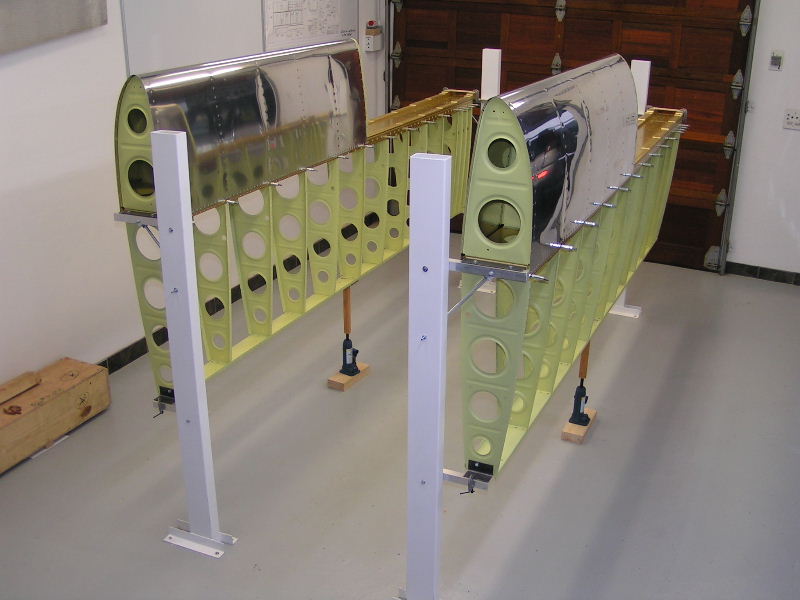

I had a lot of queries on my alternative wing metal wing stands. It is not a replacement for Van's design, just an alternative. I just had to make a set of stands that did not have to be supported on the top i.e. the ceiling because my garage door needs to open. The idea is not new, I used a lot of ideas out there and consolidate it and simply created it. These stands are made out of 2x4 steel post welded to 2x2 steel angle feet and bolted to the floor. The horisontal arm is adjustable on a threaded rod to level out after mounting the posts on the floor. Check your Van's drawings for mounting the wing and the distance between the posts. Good Luck!

PS: the website has changed it is now www.RudiGreyling.com

Additional High Resolution pictures can be seen on my website http://www.rudigreyling.com/rv7.htm Just click on the TIPS section on the left and follow the link to the wing stands.

Please ask any question in THIS post in order to keep the information together for guys coming after us. If need be I will update the above drawing with revisions, if something is unclear, so that the latest drawing is always on top.

Kind Regards

Rudi

I had a lot of queries on my alternative wing metal wing stands. It is not a replacement for Van's design, just an alternative. I just had to make a set of stands that did not have to be supported on the top i.e. the ceiling because my garage door needs to open. The idea is not new, I used a lot of ideas out there and consolidate it and simply created it. These stands are made out of 2x4 steel post welded to 2x2 steel angle feet and bolted to the floor. The horisontal arm is adjustable on a threaded rod to level out after mounting the posts on the floor. Check your Van's drawings for mounting the wing and the distance between the posts. Good Luck!

PS: the website has changed it is now www.RudiGreyling.com

Additional High Resolution pictures can be seen on my website http://www.rudigreyling.com/rv7.htm Just click on the TIPS section on the left and follow the link to the wing stands.

Please ask any question in THIS post in order to keep the information together for guys coming after us. If need be I will update the above drawing with revisions, if something is unclear, so that the latest drawing is always on top.

Kind Regards

Rudi

Last edited: