Mike S

Senior Curmudgeon

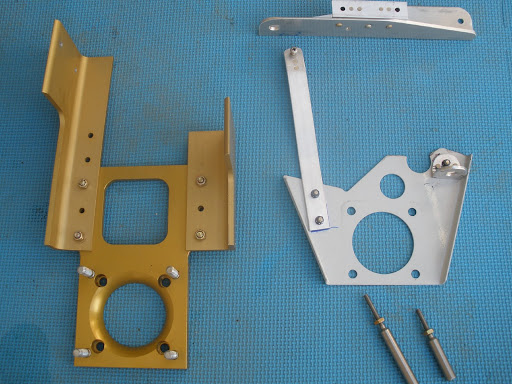

So, what do you do if there is a BIG hole in your lower cowl???

How about covering it up with something like this???

Now, you are probably wondering why would I want to cut up a perfectly good cowl, and add a new hunk of plastic to it??

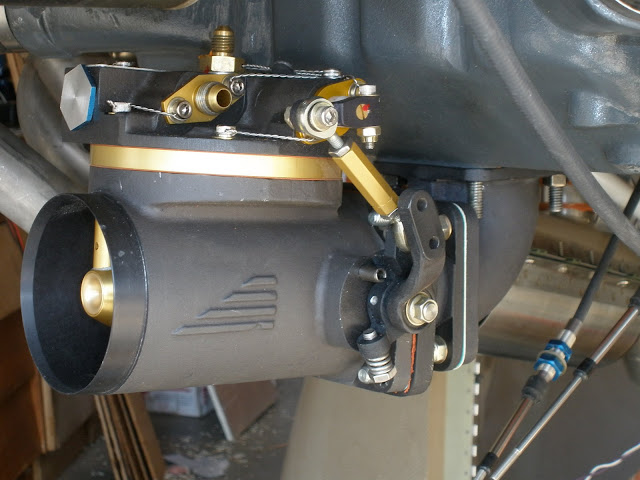

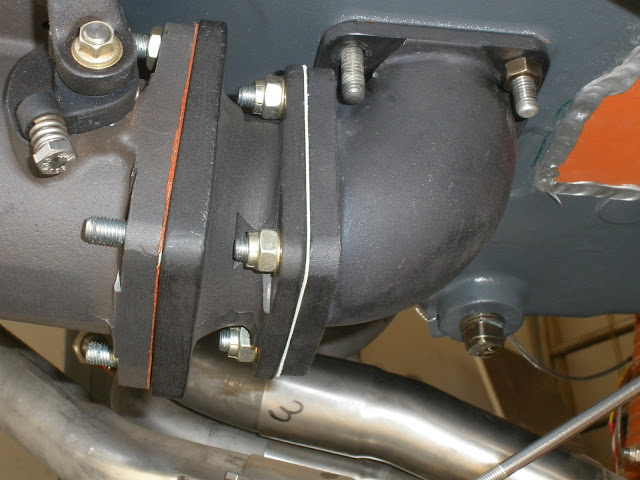

Maybe, just maybe, it is to accommodate something like this???

O.K., not exactly like the above, but so close most folks might not see the difference, and besides, I dont have a shot of the finished unit yet.

What does it all mean???

Rod Bower, the ram air guy, is working up a package for the RV 10.

If interested, contact Rod for details.

How about covering it up with something like this???

Now, you are probably wondering why would I want to cut up a perfectly good cowl, and add a new hunk of plastic to it??

Maybe, just maybe, it is to accommodate something like this???

O.K., not exactly like the above, but so close most folks might not see the difference, and besides, I dont have a shot of the finished unit yet.

What does it all mean???

Rod Bower, the ram air guy, is working up a package for the RV 10.

If interested, contact Rod for details.

Last edited: