Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

zip tie abrasion?

- Thread starter prkaye

- Start date

well, yes and no. mostly no though in my opinion. Zip ties are used by OEMs all the time without much trouble. I do know that zip ties on engine mounts will cut into the metal after some time in use(use adel clamps there) I have personally not seen zip ties cut into wiring in an aircraft but my 1993 truck did have that happen to it, I assume the tefzel wire you are most likely using will not have that problem. Wax string is a good alternative, its very clean looking and you wont cut your arms later when working on something around it. If you use zip ties get yourself a pair of snap on flush cut dykes, yes get the snap on ones as they are the best, a true flush cut will give you a nice smooth zip tie finish. Or get yourself a set of cable tie tensioner/cutters.

wil

Well Known Member

A United Airlines supervisor in their electronics shop advised us a an EAA meeting not to use zip ties on wire bundles. He said Boeing and United Airlines forbid zip tie use. Airbus on the other hand uses zip ties. United Airlines replaces all Airbus zip ties, and hand ties the wire bundles during maintenance.

I don't know if an RV would have the high frequency vibrations that an airliner experiences, I rather doubt it. I will still hand tie all my wire bundles in my RV, just in case.

I don't know if an RV would have the high frequency vibrations that an airliner experiences, I rather doubt it. I will still hand tie all my wire bundles in my RV, just in case.

Depends ?

If you are putting them around a bundle to hold the wires together, there should be no movement and thus no possiblity of abraision. If you are securing a bundle to a stationary object, tiedown, attach point, etc, then there might be some possiblity of abraision via the movement between the wire bundle and the attach point. I used a wrap of velcro at the attach point on the bundle and then the tie around that just to make sure but I think it overkill.

Metal abaision on the motor mount etc. comes from grit getting under the tie and then movement creating a grinding action!

soooo I'm told

Just my .02

Bill S

7a finishing

If you are putting them around a bundle to hold the wires together, there should be no movement and thus no possiblity of abraision. If you are securing a bundle to a stationary object, tiedown, attach point, etc, then there might be some possiblity of abraision via the movement between the wire bundle and the attach point. I used a wrap of velcro at the attach point on the bundle and then the tie around that just to make sure but I think it overkill.

Metal abaision on the motor mount etc. comes from grit getting under the tie and then movement creating a grinding action!

soooo I'm told

Just my .02

Bill S

7a finishing

briand

Well Known Member

Any special kind of knot or string to use? Thanks for the info!

http://www.aeroelectric.com/articles/cable_lace/cable_lace.html

http://www.aircraftspruce.com/catalog/elpages/BreydenLacingTapes.php

I'm using P/N 11-12170

RVG8tor

Well Known Member

Zip ties and big iron

I am not sure the info about Boeing is correct. I fly the 757-ER and since building I look at this stuff all the time. Behind one of our big panels is all kinds of wire bundles and there area zip ties everywhere so I think it is accepted practice now. Gary of Aerotronic prefers wax lace cord but he said if I were going to use a zip tie use a long enough one so you can loop it over itself before engaging the zip lock. This will help keep you from zipping it too tight. The issue with ware with zip ties is that if you get them too tight then you can get ware through the insulation. I am by not means an expert just passing along what I learned from Gary. I am using zip ties as temporary holders then I am going back with lace cord for the final assembly.

The know I learned was to make a loop out of the cord ("us shape") but this around cord and pull the tail through the loop, not wrap the tails in opposite directions around the wire bundle and finish with know on top, I use a square know but there might be some other fancy know to use here. I think AC 43 shows a clove hitch kind of knot but I am using what the guy that does panels for a living taught me, very simple and effective. I am just getting my first wire runs tied up in the tail.

Cheers

I am not sure the info about Boeing is correct. I fly the 757-ER and since building I look at this stuff all the time. Behind one of our big panels is all kinds of wire bundles and there area zip ties everywhere so I think it is accepted practice now. Gary of Aerotronic prefers wax lace cord but he said if I were going to use a zip tie use a long enough one so you can loop it over itself before engaging the zip lock. This will help keep you from zipping it too tight. The issue with ware with zip ties is that if you get them too tight then you can get ware through the insulation. I am by not means an expert just passing along what I learned from Gary. I am using zip ties as temporary holders then I am going back with lace cord for the final assembly.

The know I learned was to make a loop out of the cord ("us shape") but this around cord and pull the tail through the loop, not wrap the tails in opposite directions around the wire bundle and finish with know on top, I use a square know but there might be some other fancy know to use here. I think AC 43 shows a clove hitch kind of knot but I am using what the guy that does panels for a living taught me, very simple and effective. I am just getting my first wire runs tied up in the tail.

Cheers

az_gila

Well Known Member

AC 43.13 - aka "The Bible"...

...says it's certainly OK --

Chapter 11 of the AC

Table 11-22 give the appropriate Mil-Spec - MS3367 -- and, amazingly enough, this is one instance where the Aviation Dept. of Ace Hardware actually sells aviation approved items....

http://www.acehardware.com/product/index.jsp?productId=3766893

...I've also seen the Mil-Spec ties in the Aviation Dept. of Home Depot - just stay away from the cheap import ones.

I like the look of string ties though, but ty-raps are usually quicker to install.

Is there a serious risk associated with the possibility of nylon zip ties chaffing through wire insulation if I use them for wire bundling?

...says it's certainly OK --

Chapter 11 of the AC

Table 11-22 give the appropriate Mil-Spec - MS3367 -- and, amazingly enough, this is one instance where the Aviation Dept. of Ace Hardware actually sells aviation approved items....

http://www.acehardware.com/product/index.jsp?productId=3766893

...I've also seen the Mil-Spec ties in the Aviation Dept. of Home Depot - just stay away from the cheap import ones.

I like the look of string ties though, but ty-raps are usually quicker to install.

BoilermakerRV

Well Known Member

Kitplanes

Stein did a nice write up on wiring in the August 2009 issue of Kitplanes. There's even a nice pictorial description of tying the lacing cord.

Good luck!

Any special kind of knot or string to use? Thanks for the info!

Stein did a nice write up on wiring in the August 2009 issue of Kitplanes. There's even a nice pictorial description of tying the lacing cord.

Good luck!

AlexPeterson

Well Known Member

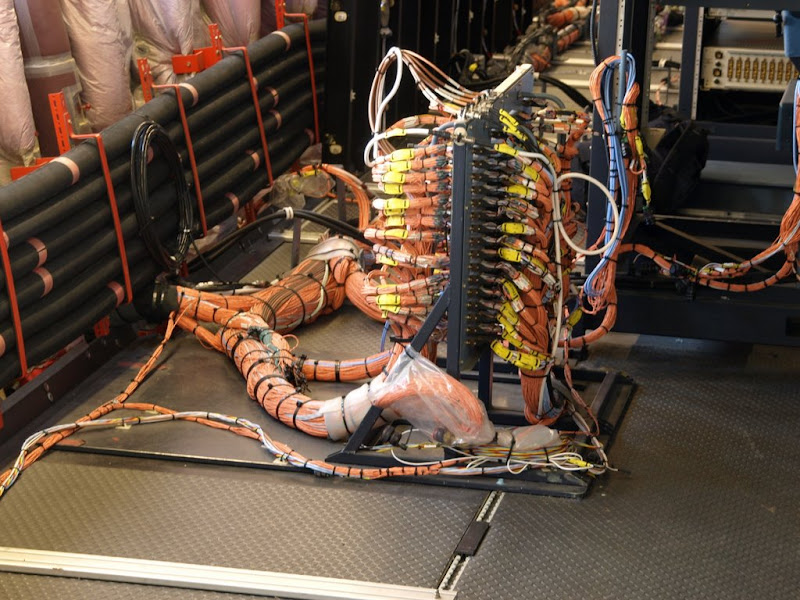

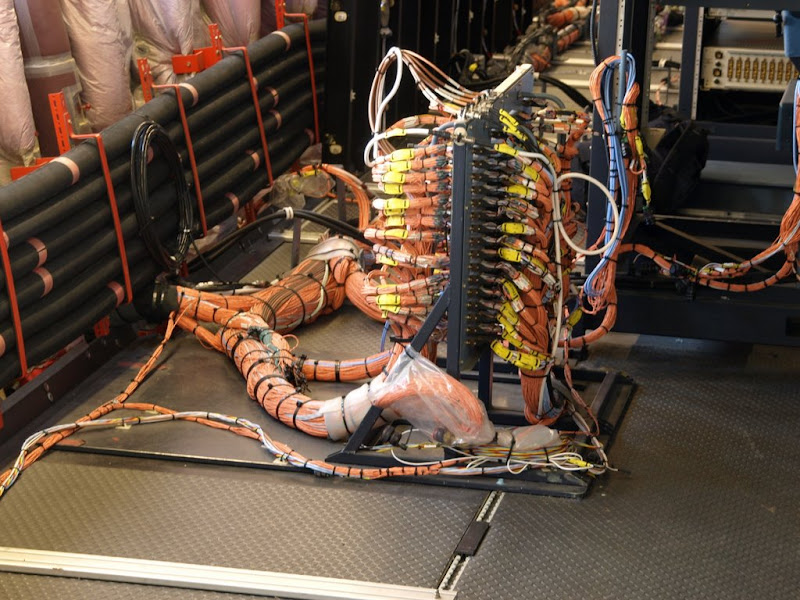

Here's a wiring nightmare in the A380 test plane (this obviously won't remain once the normal interior is put in:

This picture is shot looking left into a cargo door near the nose gear, lots of zip ties.

This picture is shot looking left into a cargo door near the nose gear, lots of zip ties.

LifeofReiley

Well Known Member

Old wives tale... tie wraps will give you service long after you and I are gone.

carguy614

Well Known Member

Wire ties and the engine mount.

I was told by 2 seperate A&P's, and an FAA inspector to make sure that there is a piece of tape around the engine mount tubes at every zip tie location if you decide to secure your wiring that way. I prefer the adel route, but a narrow band of that awesome Gorilla tape under the tie will certainly protect the tube, and it gives the bundle a stabilizing grip as well. I keep an eye on this whenever I have the cowl off. So far, so good!!

Also, I have used the Cobra tie. It traps the sharp end and lies flat on the bundle. Can't pull them up as tight as the standard ones though. Really neat, but I have mixed emotions....

HTH,

Chris

I was told by 2 seperate A&P's, and an FAA inspector to make sure that there is a piece of tape around the engine mount tubes at every zip tie location if you decide to secure your wiring that way. I prefer the adel route, but a narrow band of that awesome Gorilla tape under the tie will certainly protect the tube, and it gives the bundle a stabilizing grip as well. I keep an eye on this whenever I have the cowl off. So far, so good!!

Also, I have used the Cobra tie. It traps the sharp end and lies flat on the bundle. Can't pull them up as tight as the standard ones though. Really neat, but I have mixed emotions....

HTH,

Chris

Rick6a

Well Known Member

Same result either way....

For bundling most wires, zip ties will work just fine. I prefer using lacing cord (aft of the firewall) because it is the material of choice used on virtually all the military aircraft I once helped build. Once you get the hang of tieing the knot, (clove hitch/square knot) it is a really quick and simple way to secure wire bundles and with no sharp tabs to cut your arm on later. The only tool required is scissors or pocket knife. I can't count the number of times I've cut away knots to add or subtract wires to a given bundle. You can quickly change the number or alter knot spacing on the slightest of a whims. Certainly all this can all be done with nylon zip ties but to me it comes down to what I perceive as a cosmetic issue. Lacing cord with its signature "pigtail" sprouting from the center of the knot just seems more "military" to me....... I will still hand tie all my wire bundles in my RV, just in case.

Here's a wiring nightmare in the A380 test plane (this obviously won't remain once the normal interior is put in:

This picture is shot looking left into a cargo door near the nose gear, lots of zip ties.

Looks like most of the zip ties are on the orange (flight test) wires. All the production wiring is braided and secured with adel clamps, as I would expect.

Jamie

Well Known Member

Table 11-22 give the appropriate Mil-Spec - MS3367 -- and, amazingly enough, this is one instance where the Aviation Dept. of Ace Hardware actually sells aviation approved items....

My local Frys electronics also has MS3367 zip ties.

Bubblehead

Well Known Member

It looks like on the 380 where the zip ties are used there is some sort of wrap under them. What do they use for the wrap?

Pilottonny

Well Known Member

Tie-raps are fun!

I used cable ties all over. Made sure they are nice and thight so that nothing can vibrate, chafe or move around. I have no doubts this will be OK for many decades! I used a couple of thousend of them, added a few wires to the bundle: snip, snip, snip and add new ties around the new bundle,..... and so on.

Look under the bonnet of your car: lots of tie-raps there and they are not chafing through anything! Not through the wires nor through anything else.

I looked under the "bonnet" of a 1970's C152, a couple of weeks ago, guess what?: Loads of tie-raps! Been ther for many, many years without any problem!

At the moment I am no loosing any sleep over it.

Regards, Tonny.

I used cable ties all over. Made sure they are nice and thight so that nothing can vibrate, chafe or move around. I have no doubts this will be OK for many decades! I used a couple of thousend of them, added a few wires to the bundle: snip, snip, snip and add new ties around the new bundle,..... and so on.

Look under the bonnet of your car: lots of tie-raps there and they are not chafing through anything! Not through the wires nor through anything else.

I looked under the "bonnet" of a 1970's C152, a couple of weeks ago, guess what?: Loads of tie-raps! Been ther for many, many years without any problem!

At the moment I am no loosing any sleep over it.

Regards, Tonny.

Frank Smidler

Well Known Member

Evidence of wire tie wearing through engine mount?

I was looking at a friend's 2008 Champ yesterday and it had wire ties attached directly to the engine mount. Apparently it is not an FAA requirement to put tape on the tube prior to installing the tie Wraps or they would not be allowed to do it on a brand new aircraft. That said, I prefer to put Safety tape on the engine mount prior to installing the tie wraps if for no other reason than to keep the paint from wearing. For all the old wives tales of wire ties wearing through engine mounts has anyone ever actually seen this? Does anyone have picture evidence and info on the circumstances?

I was told by 2 seperate A&P's, and an FAA inspector to make sure that there is a piece of tape around the engine mount tubes at every zip tie location if you decide to secure your wiring that way. I prefer the adel route, but a narrow band of that awesome Gorilla tape under the tie will certainly protect the tube, and it gives the bundle a stabilizing grip as well.

I was looking at a friend's 2008 Champ yesterday and it had wire ties attached directly to the engine mount. Apparently it is not an FAA requirement to put tape on the tube prior to installing the tie Wraps or they would not be allowed to do it on a brand new aircraft. That said, I prefer to put Safety tape on the engine mount prior to installing the tie wraps if for no other reason than to keep the paint from wearing. For all the old wives tales of wire ties wearing through engine mounts has anyone ever actually seen this? Does anyone have picture evidence and info on the circumstances?

For bundling most wires, zip ties will work just fine. I prefer using lacing cord (aft of the firewall) because it is the material of choice used on virtually all the military aircraft I once helped build. Once you get the hang of tieing the knot, (clove hitch/square knot) it is a really quick and simple way to secure wire bundles and with no sharp tabs to cut your arm on later. The only tool required is scissors or pocket knife. I can't count the number of times I've cut away knots to add or subtract wires to a given bundle. You can quickly change the number or alter knot spacing on the slightest of a whims. Certainly all this can all be done with nylon zip ties but to me it comes down to what I perceive as a cosmetic issue. Lacing cord with its signature "pigtail" sprouting from the center of the knot just seems more "military" to me.

That is how we tie up the harnesses on all our engines here at the shop.

(Pratt & Whitney Overhaul and Repair)