Bob,

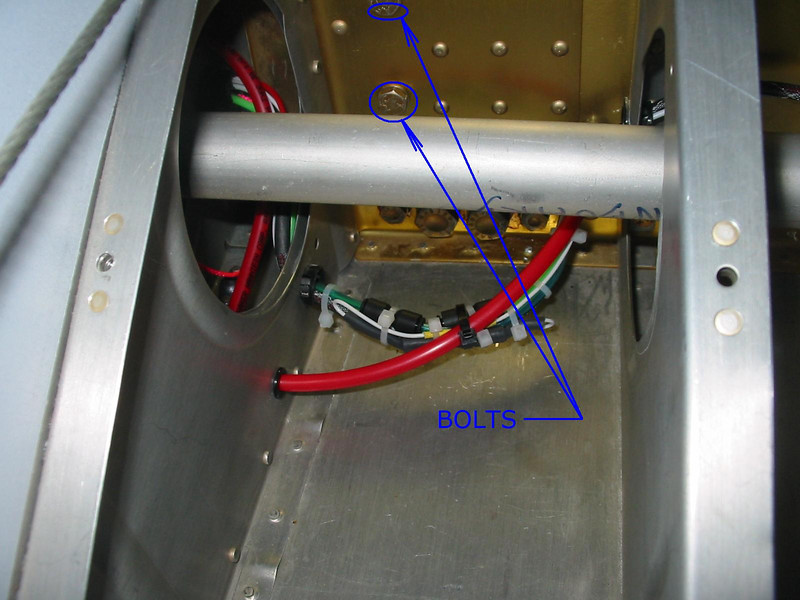

Are you referring to QA as it relates to the materials sent from Vans or are you thinking in terms of the builder? Either way your comment sounds like a non-builder comment. I say that because as a builder, I missed the install on my plane. I agree my QA was lacking in regards to these bolts but I know how I missed the installation of these bolts. However, I would absolutely disagree with you if you are implying there was a QA problem with the kit materials Vans sends to builders.

It is my impression you are thinking when installing these bolts there would be X number in the kit and if you had 4 bolts in your bin left over you know something is missing on the airplane. Well perhaps in a professional manufacturing facility there would be multiple people along with multiple procedures in place that would track all hardware at all times. As much as I would like to operate like that in my shop I am afraid it doesn't work quite that way. I have bins that house all types and sizes of bolts. When I need a 4-13A bolt I walk over to the 4-13A bolt bin and take one out. There may be 5, 10, 15, who knows how many bolts sitting in that bin. Definitely not just the exact amount needed to install the wing spar.

So, if you are thinking there should be better QA in order to know exactly how many 4-13A bolts Vans had in the kit, in my shop those Vans bolts ended up in a bin with a bunch of other 4-13A bolts from Aircraft Spruce (and yes they are all new bolts). I have to take responsibility for not installing these bolts. I was the builder. I was the person doing the work and following the plans. And the plans do indeed call out these bolts. Somehow I missed them. I don't like it for a minute that I did. At the same time I am thankful for a resource such as this forum that gives me the opportunity to have people I don't even know press me to stay on top of these type of issues and to be critical of my work. Without any of this I would still be ignorant of these missing bolts. Who knows the consequences of that behavior? Honestly I don't know how anyone can build, own or fly any of these planes without having the access to other builders and pilots like we find on this forum.

Perhaps if I had prepped the wing install better by gathering all called out hardware and placing them in separate containers on a "build" table I would have been better prepared for the QA examination of the build. Given this was my first RV build that idea is something I will take to any future RV build for sure, if I ever do build another RV. The saying goes: "Ignorance is bliss, but with knowledge comes wisdome". Well I consider myself a little less ignorant now and just a bit wiser having made this mistake, the many others I made to this point and, I am sure, from the ones I will make in the future. I will never be able to avoid making mistakes, but when I do make a mistake again I hope I never stop learning from it.

Live Long and Prosper!