Adequate Flare?

I'm trying to flare 3/8" fuel lines using the Imperial 2-piece flaring tool & a couple drops of oil. I've practice at least 20 flares, and I think I must be doing something wrong.

I've watched several videos, followed the VAF threads as well as the instructions that come with the tool and section 5 of the KAI. I've tried cranking on the tool both lightly and as hard as I can. I've tried starting with the end of the tubing flush with the top of tool and with it slightly above it.

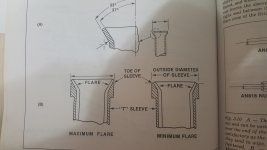

Attached below are photos of my best flare next to a T.S. Flightlines flare (on the right), and I'm obviously not getting as much of a "neck" on my flares. The last photo is my flare with a sleeve.

My questions are whether my flares are likely to be adequate or not. If not, any tips would be appreciated. I'm also wondering if I just need to break down and buy the Rolo-Flare tool which is the alternative flaring tool carried by Aircraft Spruce.

I'm trying to flare 3/8" fuel lines using the Imperial 2-piece flaring tool & a couple drops of oil. I've practice at least 20 flares, and I think I must be doing something wrong.

I've watched several videos, followed the VAF threads as well as the instructions that come with the tool and section 5 of the KAI. I've tried cranking on the tool both lightly and as hard as I can. I've tried starting with the end of the tubing flush with the top of tool and with it slightly above it.

Attached below are photos of my best flare next to a T.S. Flightlines flare (on the right), and I'm obviously not getting as much of a "neck" on my flares. The last photo is my flare with a sleeve.

My questions are whether my flares are likely to be adequate or not. If not, any tips would be appreciated. I'm also wondering if I just need to break down and buy the Rolo-Flare tool which is the alternative flaring tool carried by Aircraft Spruce.

Attachments

Last edited: