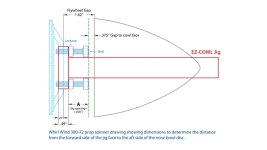

I am trying to determine beforehand the spacing I need from my engine flywheel and the front of the cowl lip to mount a WW200RV propeller. I have talked to the WW folks the answer's I get are,

"The distance from the rear bulkhead to the mounting flange of the propeller is 1.600 inches" ?? &

"you need approx. 1.6 inches from the front of the flywheel to the edge of the cowling." This one I at least understand.

I have measured from the front of my flywheel and I have 1.7 inches, (stock VANS cowl) but don't know for sure it that's the correct place to measure.

I'm just trying to determine if I may need some sort of spacer.

Does anybody have a photo of their WW200RV installed or can you furnish information on what I'm really supposed to measure.

"The distance from the rear bulkhead to the mounting flange of the propeller is 1.600 inches" ?? &

"you need approx. 1.6 inches from the front of the flywheel to the edge of the cowling." This one I at least understand.

I have measured from the front of my flywheel and I have 1.7 inches, (stock VANS cowl) but don't know for sure it that's the correct place to measure.

I'm just trying to determine if I may need some sort of spacer.

Does anybody have a photo of their WW200RV installed or can you furnish information on what I'm really supposed to measure.