flyboy1963

Well Known Member

Had to start a new thread, the old ones seem DOA.

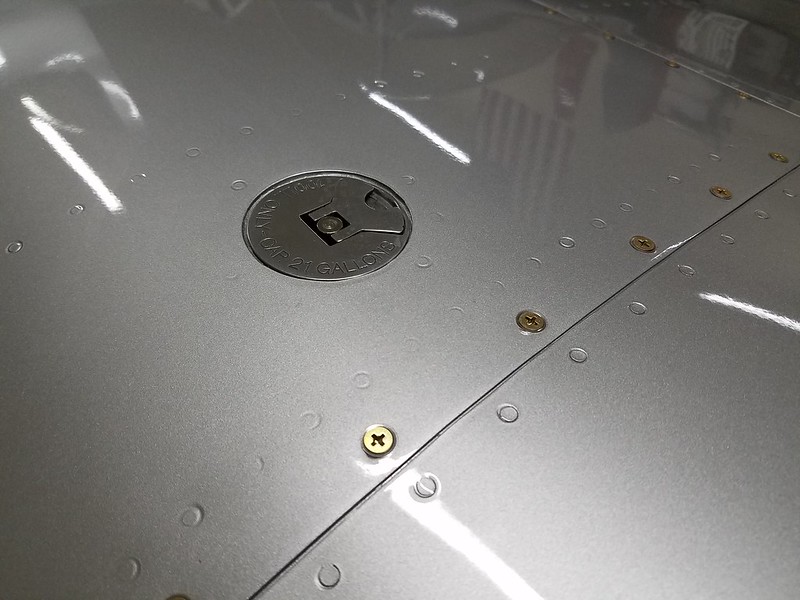

problem: RV-9 with left gauge not reading correctly.

there seem to be numerous references to pulling the fuel sender for inspection/repair, and the larger cover plate for various reasons ( leaks) ...but I can't see how you'd do this with the tank in place?

please educate me....can it be done, or not worth it, as I can see it being hard to re-install correctly, and seal etc.

thanks to all who read and/or advise!

problem: RV-9 with left gauge not reading correctly.

there seem to be numerous references to pulling the fuel sender for inspection/repair, and the larger cover plate for various reasons ( leaks) ...but I can't see how you'd do this with the tank in place?

please educate me....can it be done, or not worth it, as I can see it being hard to re-install correctly, and seal etc.

thanks to all who read and/or advise!