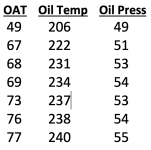

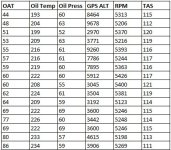

I have documented OAT, Oil Temp, and Oil Press in stabilized cruise flight at near gross weight and 3000’ MSL. Rotax states 260F Max Allowed Oil Temp with 190-230F Normal Range. I have been using Full Synthetic Mobil1 4T 10W40 for last 650 hours.

Note items #1 and #4 in section 6 of Rotax Service Instruction below:

Rotax Service Instruction Titled: Selection of Suitable Operating Fluids for ROTAX® Engine Type 916 i (Series), 915 i (Series), 912 i (Series), 912 and 914 (Series). The publication is dated May 28, 2021. pdf file is d06902.pdf in the Technical Documentation Section of

https://www.flyrotax.com.

Section 6 states:

6) General Engine Operation Requirements and Operating Tips

1. Keep the engine oil temperature below 120 °C (250 °F) over most of the operating period.

2. Always ensure that the oil type used is adequate for climatic conditions and peak engine operating temperatures. If operational oil temperatures exceed 120 °C (250 °F), use of a mineral or petroleum based oil is not recommended.

3. For turbocharged engines ensure an adequate running cool-down period to prevent deposits by coking of oil.

4. When operating with unleaded fuels or MOGAS and when engine oil temperatures often exceed 120 °C (250 °F) use of a high quality full synthetic oil is recommended.

5. To avoid formation of condensation water in the engine oil, the oil temperature must rise at least once every operational day to at least 100 °C (212 °F).

6. Avoid extended use of carburetor air pre-heating when safe and reasonable.

7. Automotive fuels have seasonal blends and MUST be used in the correct season. Failure to do so can cause hard starting or serious issues like vapor lock.

8. Depending on the type of fuel used, operating conditions, and the demands of the engine mission profile it may be necessary to increase the frequency of oil changes to avoid the excessive build- up of lead and other residues in the engine oil. Always adjust the engine oil change intervals to avoid excessive build-up of sludge in the engine oil.

-