koupster

Well Known Member

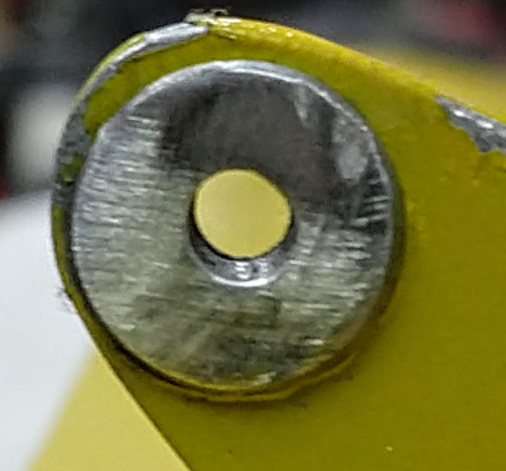

My trim tab had quite a bit of play. The hole in the arm had probably been drilled with a # 30 drill bit (.1285) and was elongated a bit from wear. The clevis pin measured .122.

The hole in the arm was drilled out and a shortened -6 rivet was inserted. A # 32 drill bit (0.116) was used to start a hole in the factory head.

The rivet was squeezed, and through drilled with a # 32 drill bit. The factory head was ground to enable the assembly to fit back in the clevis, and the hole was reamed to .122.

All the play between the clevis and the trim tab arm is gone, and the clevis pin now runs in the .140 thick manufactured bushing rather than the two pieces of .032? aluminum that make up the arm.

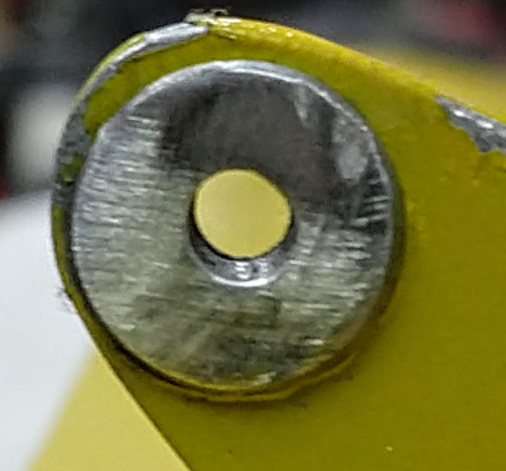

The hole in the arm was drilled out and a shortened -6 rivet was inserted. A # 32 drill bit (0.116) was used to start a hole in the factory head.

The rivet was squeezed, and through drilled with a # 32 drill bit. The factory head was ground to enable the assembly to fit back in the clevis, and the hole was reamed to .122.

All the play between the clevis and the trim tab arm is gone, and the clevis pin now runs in the .140 thick manufactured bushing rather than the two pieces of .032? aluminum that make up the arm.

Last edited: