Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do I need Alternate Air?

- Thread starter idleup

- Start date

Peter.Fruehling

Well Known Member

Matt if you want your engine to continue running if you fly in to snow, then you need it. If you don't need to keep your engine running then don't worry about it.

In all seriousness, what is the advantage to not putting it in?

- Peter

In all seriousness, what is the advantage to not putting it in?

- Peter

TX7A

Well Known Member

Matt,

It's pretty much a choice 'thing'.

Do a search & you'll find much information & opinions about alt. air.

I believe Van's had issues with the setup a few years back but now have a better solution. I will say that I have seen some very elegant solutions to the alt. air gate as opposed to Van's current system.

Like I said, do a search & you'll find lots.

It's pretty much a choice 'thing'.

Do a search & you'll find much information & opinions about alt. air.

I believe Van's had issues with the setup a few years back but now have a better solution. I will say that I have seen some very elegant solutions to the alt. air gate as opposed to Van's current system.

Like I said, do a search & you'll find lots.

pazmanyflyer

Well Known Member

Safety my friend

Anything that blocks the air intake is a problem. Bird, plastic bags in dust devils and such. If your main air intake is blocked then your alt air gives you the option to continue safe flight.

Anything that blocks the air intake is a problem. Bird, plastic bags in dust devils and such. If your main air intake is blocked then your alt air gives you the option to continue safe flight.

Toobuilder

Well Known Member

I don't know the advantage of not putting it in, I was just confused as to why some people have it and others do not...

There are advantages to not installing it, just like there are advantages to the contrary. Like many things in aviation, it's a compromise that is best decided by a cost/benefit analysis (in this case, "cost" is measured as "effort").

Some reasons to "not" install -

Weight

Complexity

More maintenance

Possible reduction in performance (leaking FAB = reduced MP)

Possible engine damage (Dirt -Leaking FAB or FOD)

Higher cost

To some these are trivial concerns, while others might think differently.

I currently fly without alternate air, but I'd like to have it if it does not interfere with my induction design. I also consider flight in any condition that would ice up and block my filter as an "emergency", so the risk of not having one is pretty low for me.

The bottom line is it is up to you.

Personally, I don't like the non-resettable alternate air. It just bugs me. It can get pulled and have the cable pushed back in so you don't know it. Then you get unfiltered air for however long its open. I do think you should have an alternate though. I like automatic alternates, but I have replaced a couple turbos that've ingested pieces of alternate doors (magnets, rivets, springs), so whatever kind of contraption you put in downstream of the filter has to be a good one.

Jamie

Well Known Member

Aerhead mentioned a good reason a lot of people don't put it in (I'm not saying you should or shouldn't). If you have alternate air it bypasses the filter (obviously). If anything in that mechanism breaks (hinge, rivet, whatever), there's a good chance it can get sucked up into the engine.

FredMagare

Well Known Member

Aerhead mentioned a good reason a lot of people don't put it in (I'm not saying you should or shouldn't). If you have alternate air it bypasses the filter (obviously). If anything in that mechanism breaks (hinge, rivet, whatever), there's a good chance it can get sucked up into the engine.

I'm not sure that your statement is true about bypassing the filter. If I recall what I've seen from other's pictures, alternate air simply blocks the through-cowl intake scoop and pulls/redirects engine cooling air into the FAB.... The result is warmer air in the intake (as well as lower MP) which may be necessary for the curtailment of carb icing.

Toobuilder

Well Known Member

I like the thought of an "automatic" alternate air, so I built one for the HB. It sealed nicely when closed, and worked seamlessly when needed. It was subject to wear during normal flight though, and the failure mode was sure to send a bunch of hardware through the servo. It worked great, but I never could get around the single point failure aspect of it. It was ultimately replaced with a section of tube. Right or wrong, I'd rather spend a ?little? time worrying about ice buildup or the freak birdstrike than the ever-present FOD time bomb living just upstream from my servo inlet.

Toobuilder

Well Known Member

I'm not sure that your statement is true about bypassing the filter. If I recall what I've seen from other's pictures, alternate air simply blocks the through-cowl intake scoop and pulls/redirects engine cooling air into the FAB.... The result is warmer air in the intake (as well as lower MP) which may be necessary for the curtailment of carb icing.

That is one type; but the "ultimate" purpose of alternate air is to bypass the filter (often the cause of the blockage) and let the engine breathe.

I'm not sure that your statement is true about bypassing the filter. If I recall what I've seen from other's pictures, alternate air simply blocks the through-cowl intake scoop and pulls/redirects engine cooling air into the FAB.... The result is warmer air in the intake (as well as lower MP) which may be necessary for the curtailment of carb icing.

Agreed completely. My alternate air has a fine mesh screen which prevents any sizable object to enter the intake but I can hardly think of a circumstance that this can happen. The suction of the intake is hardly of the same pressure as the exit air thru the cowl & gravity, so it will take a huge bad luck for any object to break away just as the alternate air is open and to be right in that vicinity to be sucked inside. Of course my setup is for a horizontal induction and slightly different setup the vertical induction.

I'm not sure that your statement is true about bypassing the filter. If I recall what I've seen from other's pictures, alternate air simply blocks the through-cowl intake scoop and pulls/redirects engine cooling air into the FAB.... The result is warmer air in the intake (as well as lower MP) which may be necessary for the curtailment of carb icing.

Fred, you're talking about the Carb Heat door on the stock (updraft) FAB - not the alternate air door, which draws air from the bottom of the FAB, through the center of the filter.

There should be lots of posts on this in the archives - hasn't been talked about a lot in th past couple of years, but a common item of debate about four or five years ago. The original design had the "automatic" door that was held shut by a magnet, and got sucked open if the filter was blocked. Unfortunately, the vibration environment caused wear, and eventually, several shed magnets and screws that were sucked in to the engine. The later design is cable operated.

I think there have been a couple of instances in the history of the RV's where the intake/filter was blocked, so each builder decides if they need the alternate path or not, based on the odds.

Paul

This thread seems to be the definitive one.

I copied the sliding gate idea used by Captain Avgas. An interesting little side project that pushed out my first flight date a few hours. I'm mostly concerned about ingesting birds, since that's happened to a few pilots around here (lots of birds in the Sacramento Valley). I won't make a case for having one though. The reasons for not doing so are pretty compelling too.

I copied the sliding gate idea used by Captain Avgas. An interesting little side project that pushed out my first flight date a few hours. I'm mostly concerned about ingesting birds, since that's happened to a few pilots around here (lots of birds in the Sacramento Valley). I won't make a case for having one though. The reasons for not doing so are pretty compelling too.

FredMagare

Well Known Member

Fred, you're talking about the Carb Heat door on the stock (updraft) FAB - not the alternate air door, which draws air from the bottom of the FAB, through the center of the filter.

Well, certainly that can't be right...it makes too much sense!

Thanks for explanation, Paul. "Learning has occurred!"

Just thinking about your explanation regarding the "alternate air" setup...what's to keep whatever it is that's blocking the filter to not get sucked-up the alternate air door when opened?

Last edited:

Toobuilder

Well Known Member

...Just thinking about your explanation regarding the "alternate air" setup...what's to keep whatever it is that's blocking the filter to not get sucked-up the alternate air door when opened?

Because whatever is blocking the filter is on the inside of the FAB, but on the "outside" of the filter... The alternate air door opens from "inside" the filter to the "outside" of the FAB.

L.Adamson

Well Known Member

Just thinking about your explanation regarding the "alternate air" setup...what's to keep whatever it is that's blocking the filter to not get sucked-up the alternate air door when opened?

In the case, of my carbed alternate air.....

The alternate air goes up through the "donut" hole of the air filter straight into the carb. The regular air, bird, or snow is up against the outsides of the donut (circumference) in the air box.

L.Adamson --- RV6A

Well, certainly that can't be right...it makes too much sense!

Thanks for explanation, Paul. "Learning has occurred!"

Just thinking about your explanation regarding the "alternate air" setup...what's to keep whatever it is that's blocking the filter to not get sucked-up the alternate air door when opened?

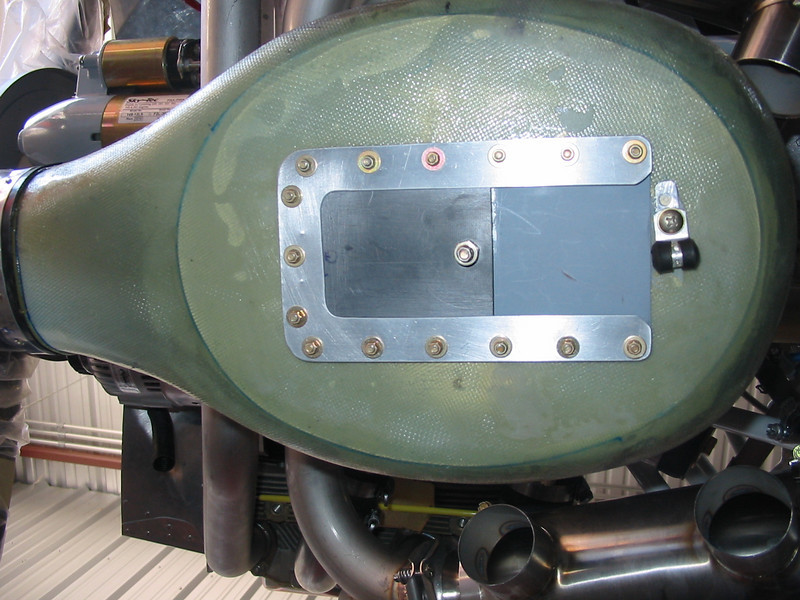

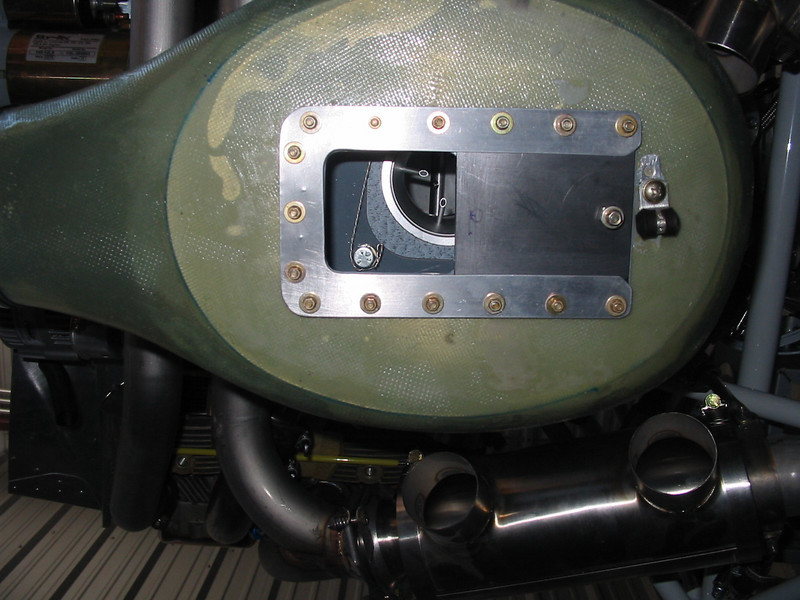

Maybe a couple of photos of my setup would be worth a few hundred words

So if something blocked the inlet/filter, I could pull the cable (obviously not yet installed on the above photos) and air would have a straight shot at the fuel injector servo.

pierre smith

Well Known Member

Nice work Lars...

...and it seems that there's little chance of any part of that getting "sucked" into the engine.

Best,

...and it seems that there's little chance of any part of that getting "sucked" into the engine.

Best,

just accidentally i fabricated the van's standard alt air and mounted it to my horizontal FAB yesterday.

after looking at it during lunch break... i just do not see how anything from that could fall into the inside of the snorkel and get sucked by the engine.

the chance will be greater to get hit by an asteroid. don't worry.

Kay

after looking at it during lunch break... i just do not see how anything from that could fall into the inside of the snorkel and get sucked by the engine.

the chance will be greater to get hit by an asteroid. don't worry.

Kay

Hey, that looks pretty great. I'm working on the alternate air door for my horizontal induction engine right now, so this is very timely. I might try to copy some of the ideas above since I'm not thrilled with the factory design.

Just wondering, what prevents a loose screw from being sucked up into the engine with this design? Is there a layer of glass over the screw heads inside the airbox?

thanks,

mcb

Just wondering, what prevents a loose screw from being sucked up into the engine with this design? Is there a layer of glass over the screw heads inside the airbox?

thanks,

mcb

Hey, that looks pretty great. I'm working on the alternate air door for my horizontal induction engine right now, so this is very timely. I might try to copy some of the ideas above since I'm not thrilled with the factory design.

Just wondering, what prevents a loose screw from being sucked up into the engine with this design? Is there a layer of glass over the screw heads inside the airbox?

thanks,

mcb

Technically, nothing prevents a screw from being sucked in. But I bonded a piece of .020 aluminum to the inside (visible in the photos, where you can even see the air bubbles where I did a less-than-stellar clamping job) which is dimpled for the #6 screws. So the fiberglass is sandwiched. On the outside, though it's hard to see, I used all-metal locknuts with screws long enough that several threads are showing. And high temp loctite, just because. The Adel clamp and its nutplate are outside the filter area. The cable clamping screw on the door is captured- the opening is small enough that it is never exposed to the interior, so the screw can't come out even if the nut comes off. None of that is perfect. This will be an assembly closely watched, once I'm running.

FredMagare

Well Known Member

This picturely certainly clears-up my confusion! Seems like a few hours of work for an additional safety measure. Why not install it? If something is sucked into the intake (let's say...an unnoticed plastic bag) that later shifts and chokes the air filter, opening the Carb Heat door would not alleviate the problem but this certainly would!

Captain Avgas

Well Known Member

Here are a couple of Pix of my alternate air slider which Lars previously referred to.

My device differs marginally from Lars' design in a number of small ways as follows:

1) I have used 1/8" rivets instead of screws and nuts.

2) I have rotated the mechanism on the FAB so that the control cable does not conflict with the aircraft nose leg assembly (A model).

3) I have placed the fasteners for the control cable adel clamp outside of the filter.

4) I have a bridge on the slider mechanism.

I'm not suggesting that any of these differences are improvements but they may be food for thought.

One thing is for sure. I'd rather have no alternate air at all than instal Van's terrible device. I can't believe they couldn't come up with a better design on their second attempt.

My device differs marginally from Lars' design in a number of small ways as follows:

1) I have used 1/8" rivets instead of screws and nuts.

2) I have rotated the mechanism on the FAB so that the control cable does not conflict with the aircraft nose leg assembly (A model).

3) I have placed the fasteners for the control cable adel clamp outside of the filter.

4) I have a bridge on the slider mechanism.

I'm not suggesting that any of these differences are improvements but they may be food for thought.

One thing is for sure. I'd rather have no alternate air at all than instal Van's terrible device. I can't believe they couldn't come up with a better design on their second attempt.

Here are a couple of Pix of my alternate air slider which Lars previously referred to.

My device differs marginally from Lars' design in a number of small ways as follows:

1) I have used 1/8" rivets instead of screws and nuts.

2) I have rotated the mechanism on the FAB so that the control cable does not conflict with the aircraft nose leg assembly (A model).

3) I have placed the fasteners for the control cable adel clamp outside of the filter.

4) I have a bridge on the slider mechanism.

I'm not suggesting that any of these differences are improvements but they may be food for thought.

One thing is for sure. I'd rather have no alternate air at all than instal Van's terrible device. I can't believe they couldn't come up with a better design on their second attempt.

I stared at the alternate air door packaged with my FAB, not liking it one bit. I wasn't surprised to see threads here questioning its utility. Bob, your posts in the thread I linked previously were the inspiration for my interpretation. Thanks for that.

Only one other thing to add- ref item 3, above: Likewise, on my airbox. All control cable fastening hardware is outboard of the filter.

Well, one other thing: seeing yours makes me think about painting mine. Without, it's really ugly.

Captain Avgas

Well Known Member

Well, one other thing: seeing yours makes me think about painting mine. Without, it's really ugly.

Lars, I'd be as comfortable with your effort as I would with mine. I think they're probably both bullet-proof.

It's nice to see that you used metal locknuts (I assume that in due course you'll torque mark them). I didn't use any nylock nuts FWF on my aircraft. Nor did I use any at the disc brakes.

Lars, I'd be as comfortable with your effort as I would with mine. I think they're probably both bullet-proof.

It's nice to see that you used metal locknuts (I assume that in due course you'll torque mark them). I didn't use any nylock nuts FWF on my aircraft. Nor did I use any at the disc brakes.

Already done, since those photos were taken. I have a limitless supply of Torque-Seal thanks to my neighbor the A&P, so I'm liberal with the stuff. No nylocks FWF.

Guys, can I offer a bit of philosophy?

Parts not on the airplane never give trouble.

One key goal is to eliminate the chance of (1) blocking the throttle bore with a loose large part or (2) ingesting a small part. I'd suggest the best way to do both is to simply eliminate the parts.

For example, do these designs really need the large aluminum sheet inside the bottom of the box? Why is it there, really? There is a chance it will crack and perhaps shed a section; the whole bottom of the box is moving like a drum head. Why not a few additional plies of glass fabric on the inside to thicken and stiffen the belly of the box?

Do the slider rails really need fasteners? Why not composite slides bonded to the outside of the box?

Parts not on the airplane never give trouble.

One key goal is to eliminate the chance of (1) blocking the throttle bore with a loose large part or (2) ingesting a small part. I'd suggest the best way to do both is to simply eliminate the parts.

For example, do these designs really need the large aluminum sheet inside the bottom of the box? Why is it there, really? There is a chance it will crack and perhaps shed a section; the whole bottom of the box is moving like a drum head. Why not a few additional plies of glass fabric on the inside to thicken and stiffen the belly of the box?

Do the slider rails really need fasteners? Why not composite slides bonded to the outside of the box?

Captain Avgas

Well Known Member

Captain Avgas

Well Known Member

Guys, can I offer a bit of philosophy?

Parts not on the airplane never give trouble.

One key goal is to eliminate the chance of (1) blocking the throttle bore with a loose large part or (2) ingesting a small part. I'd suggest the best way to do both is to simply eliminate the parts.

For example, do these designs really need the large aluminum sheet inside the bottom of the box? Why is it there, really? There is a chance it will crack and perhaps shed a section; the whole bottom of the box is moving like a drum head. Why not a few additional plies of glass fabric on the inside to thicken and stiffen the belly of the box?

Do the slider rails really need fasteners? Why not composite slides bonded to the outside of the box?

Dan, as usual, your comments have considerable merit. In the final analysis only time in service proves any new design (even yours

I opted for the plate inside because I had read of a number of instances where the filter had worn into the composite FAB, in some instances allowing unfiltered air to pass....and in some instances wearing right through the bottom of the FAB. So the plate inside (which extends out beyond the filter) is to prevent wear of the composite and also to act as a backing plate for the fasteners. I doubt that the plate will crack because it is not subjected to any significant flexural action. The plate that is most likely to crack (and often does) is the main plate bolted to the fuel injector/carburettor that supports the whole FAB. This latter plate often cracks because the FAB is relatively restrained (and therefore unable to accomodate full engine movement) at the FAB to cowl inlet mating (another poor design in my opinion).

Of course the easiest and fastest thing to do is leave out the alternate air altogether (as many builders do). Just take your chances. In my case I didn't think that was a sensible option because I fly a fair bit of IFR and I know how easy it is to end up flying through snow despite the best laid plans to avoid the stuff.

Alternate air is like a fire extinguisher....one will probably never need it in a lifetime of flying....but if one DOES need it, and it is not available, then that lifetime can be dramatically shortened.

Last edited:

Guys, can I offer a bit of philosophy?

Parts not on the airplane never give trouble.

One key goal is to eliminate the chance of (1) blocking the throttle bore with a loose large part or (2) ingesting a small part. I'd suggest the best way to do both is to simply eliminate the parts.

For example, do these designs really need the large aluminum sheet inside the bottom of the box? Why is it there, really? There is a chance it will crack and perhaps shed a section; the whole bottom of the box is moving like a drum head. Why not a few additional plies of glass fabric on the inside to thicken and stiffen the belly of the box?

Do the slider rails really need fasteners? Why not composite slides bonded to the outside of the box?

Mmmm... all composite... When I put mine together, I had a lot less confidence in my composite skills. What is trivial for the accomplished is daunting to the neophyte. It didn't even occur to me to use glass. Were I to do it again, I'd take that on. In fact I'd probably pull a splash mold off the Van's part and make a new one out of epoxy, which I prefer to the poly/vinyl ester Van's uses.

As for the interior aluminum sheet, I did it for the same reason Bob described. I've seen a couple that were worn through, or nearly so. Of course it could have been for other reasons that I didn't observe- perhaps the filter element wasn't captured well enough on those, for example. That could lead to relative movement. Throw in some grit accumulated from ground operations and you have a sanding machine. Which could happen with my aluminum sheet, though my filter is jammed in there tightly.

Bob also mentioned top plate failures. I had to make a replacement anyway in order to move the FAB to clear the lower cowl, so I made it out of 4130 (picked up some weight there, by a factor of 3 compared the same thickness aluminum). That was based on stories about that plate failing, as we've discussed in other threads. Story about that: I called Van's to order a replacement upper plate (the tennis racket shaped part) due to a blunder. When I placed the order, I was asked if I was sure if I had the correct part number. I confirmed and asked why the question. I was told that they sell lots of replacement top plates. Seems it is indeed pretty common.