BillL

Well Known Member

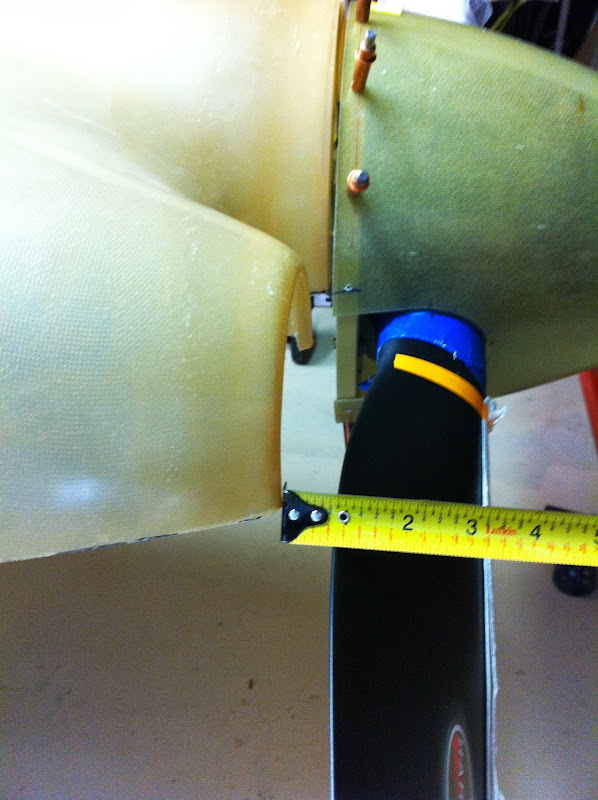

The wide cord on the Hartzell composite blade results in an issue. It appears that in the low pitch mode (10deg) that the back side of the blade is 7/8" from the front of the SJ cowl. The high pitch is 27.5deg and the cord at this point is 8 inches. By calculation, going to high pitch will move the back side of that blade 1.15". Soooo, I need to create some clearance, and it may get worse with the inlet rings installed.

Options:

1. cut the cowl just behind the spinner and move everything back .6 inches.

(my favorite)

2. somehow move the cooling inlets back .6 inches.

3. extend the spinner .6 and move the entire cowl back, yes 0.6 inches.

4. Other??

What have others done to address this issue?

BTW- I have the 2.5 in extension to reduce cowl interference possibilities.

Options:

1. cut the cowl just behind the spinner and move everything back .6 inches.

(my favorite)

2. somehow move the cooling inlets back .6 inches.

3. extend the spinner .6 and move the entire cowl back, yes 0.6 inches.

4. Other??

What have others done to address this issue?

BTW- I have the 2.5 in extension to reduce cowl interference possibilities.