Larry DeCamp

Well Known Member

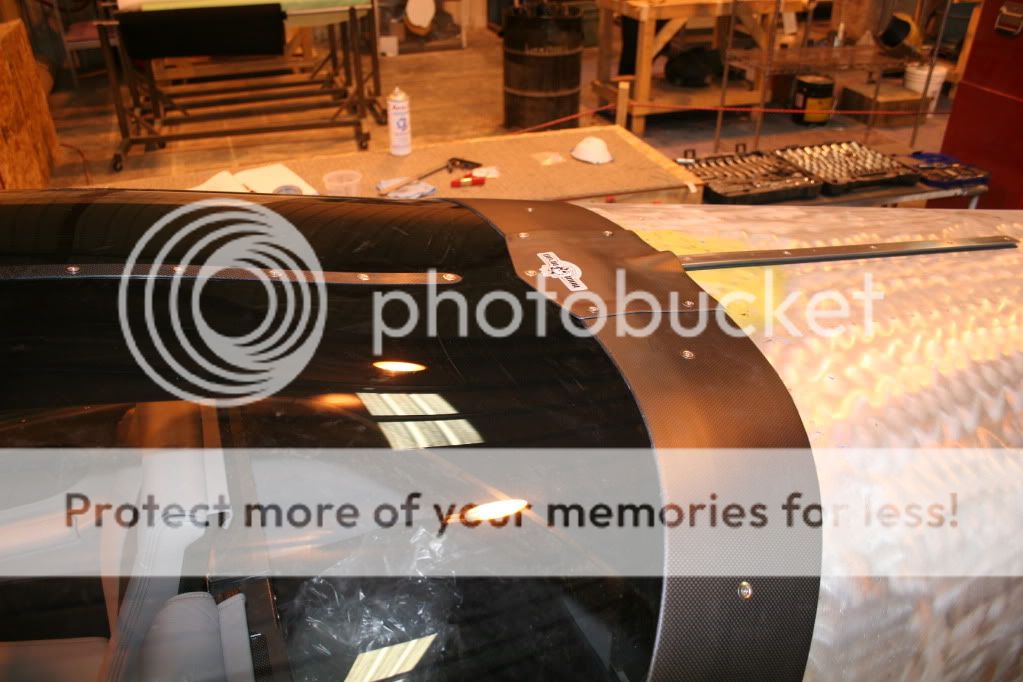

I started on my canopy install today using a TODD'S CANOPY. It does not conform well to the vans aluminum frame structure, but that is not important to me. While pondering the task, I resolved that Van's design was developed to secure plexi canopy and ALUMINUM SHEET to a tube with rivets. Today most builders use composite material for the skirt.

Varieze, Longeze and Cozy have used the composite approach with acceptable results. Therefore, I plan to build the entire canopy skirt structure with E-glass and maybe some carbon. Please point out the errors in my logic....Larry

Varieze, Longeze and Cozy have used the composite approach with acceptable results. Therefore, I plan to build the entire canopy skirt structure with E-glass and maybe some carbon. Please point out the errors in my logic....Larry