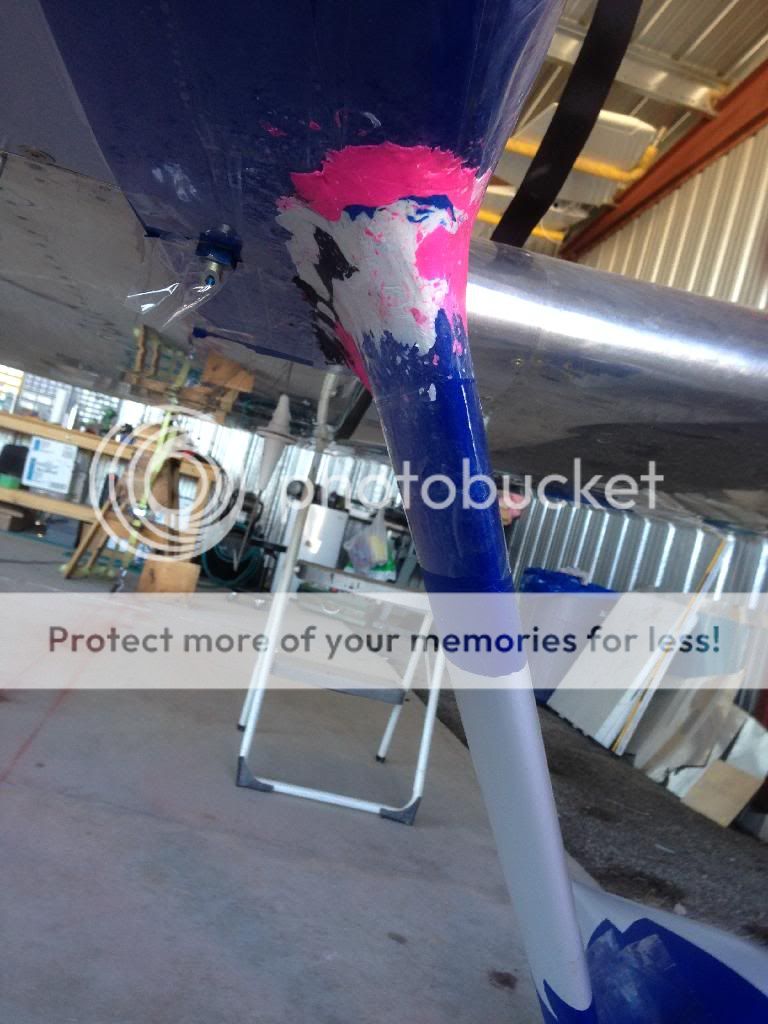

Thanks Vlad, we have the same taste in paint schemes! Here's a photo I took today of the other side.

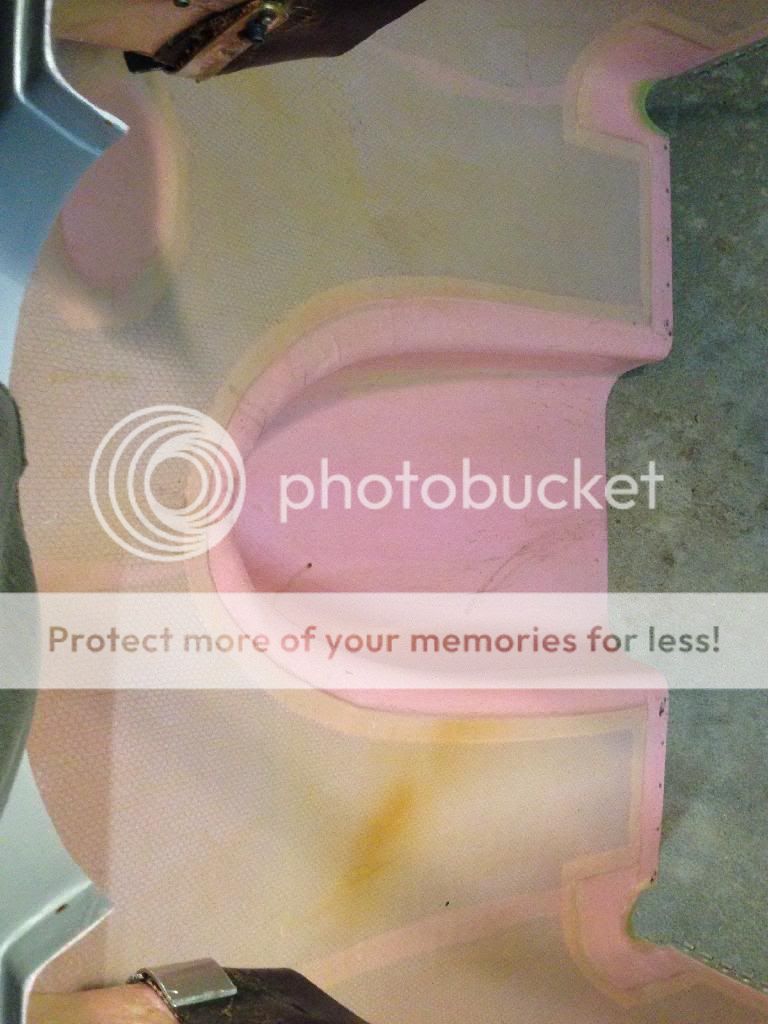

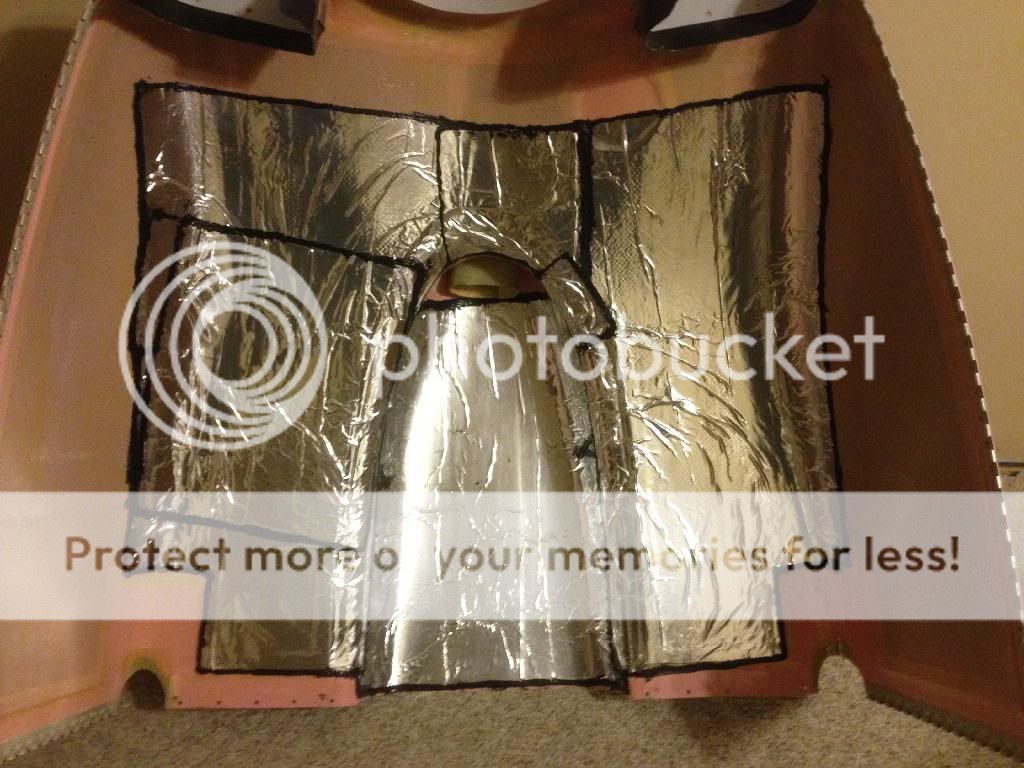

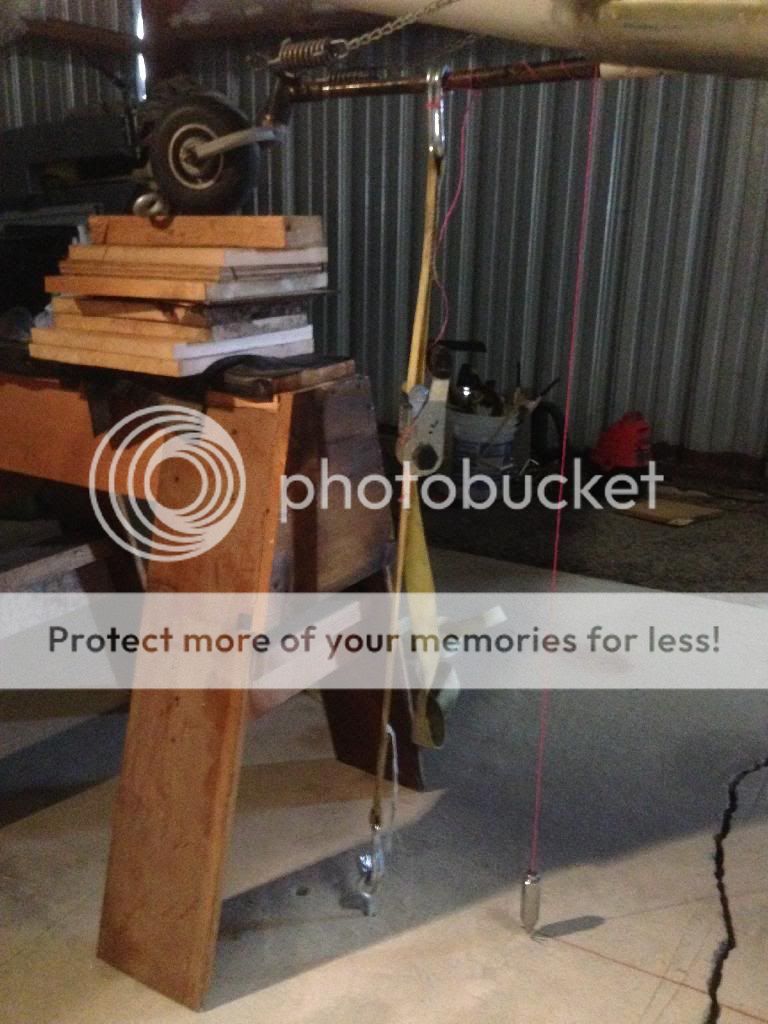

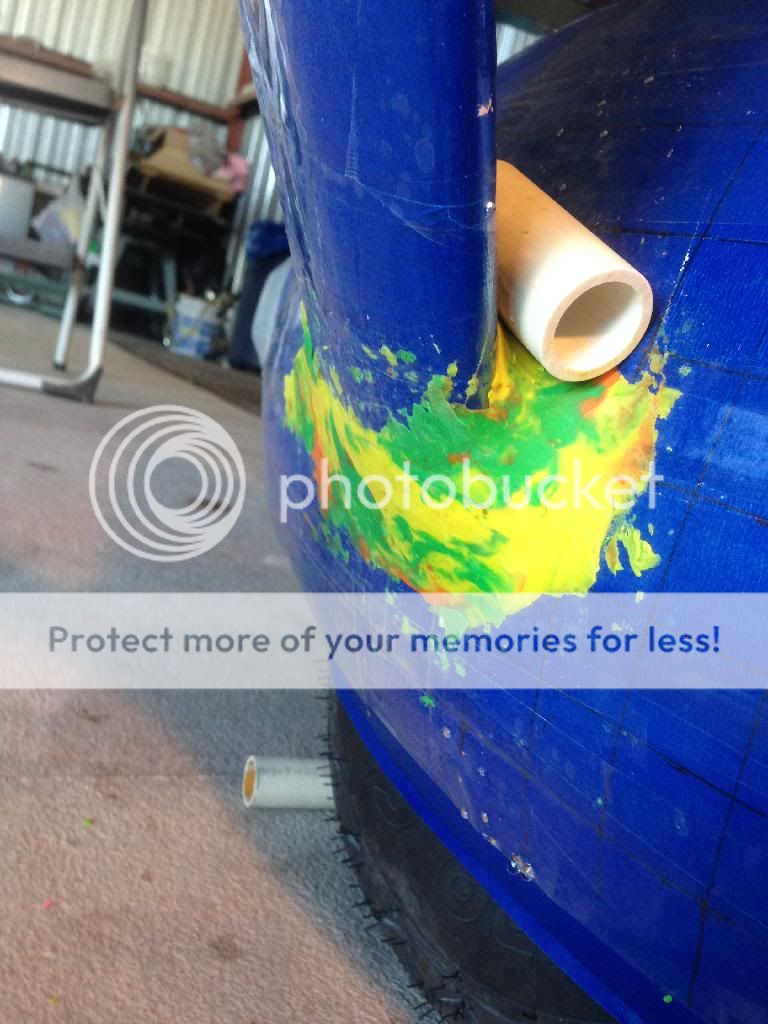

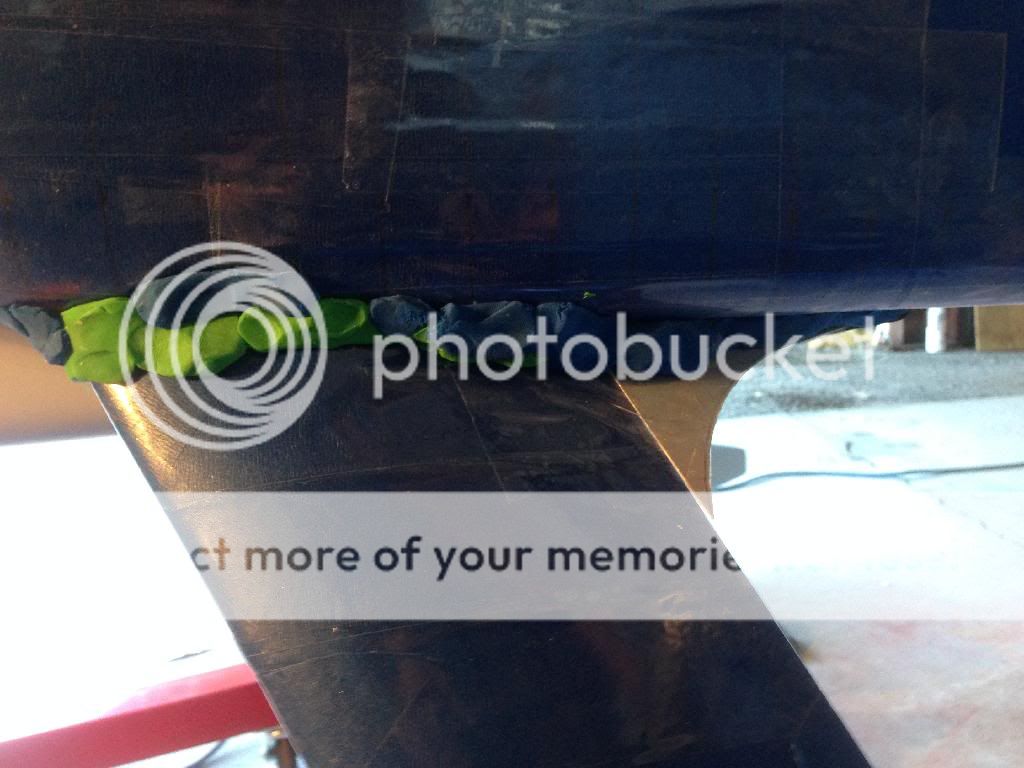

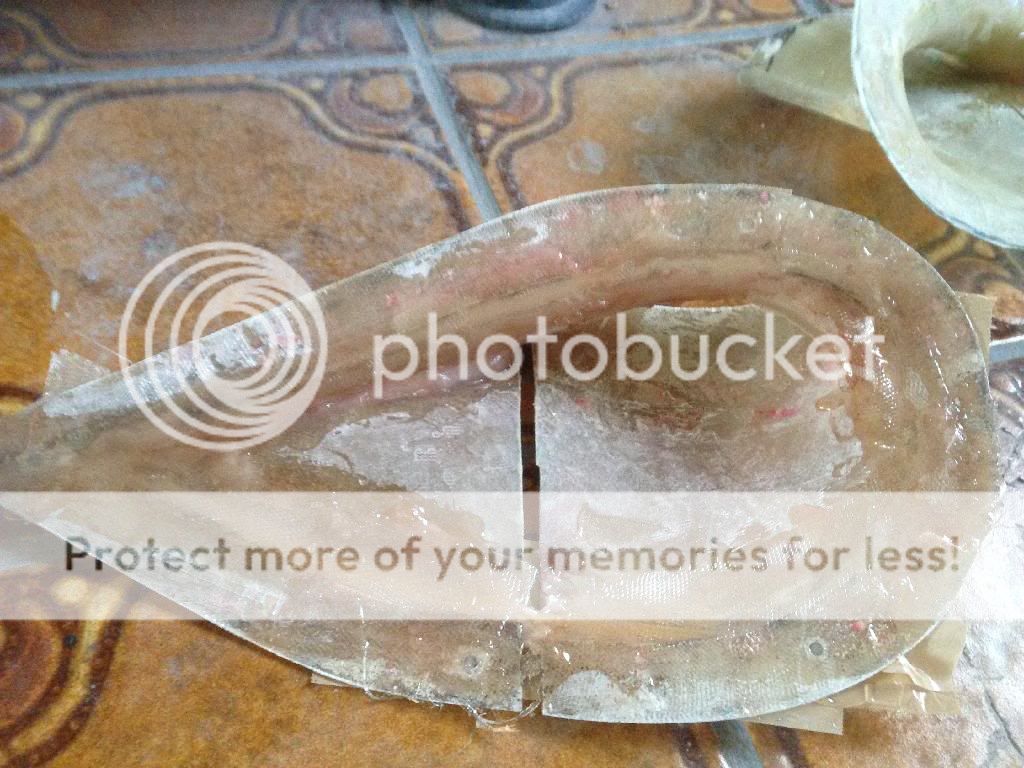

Here's the only pics I found while I was making them.

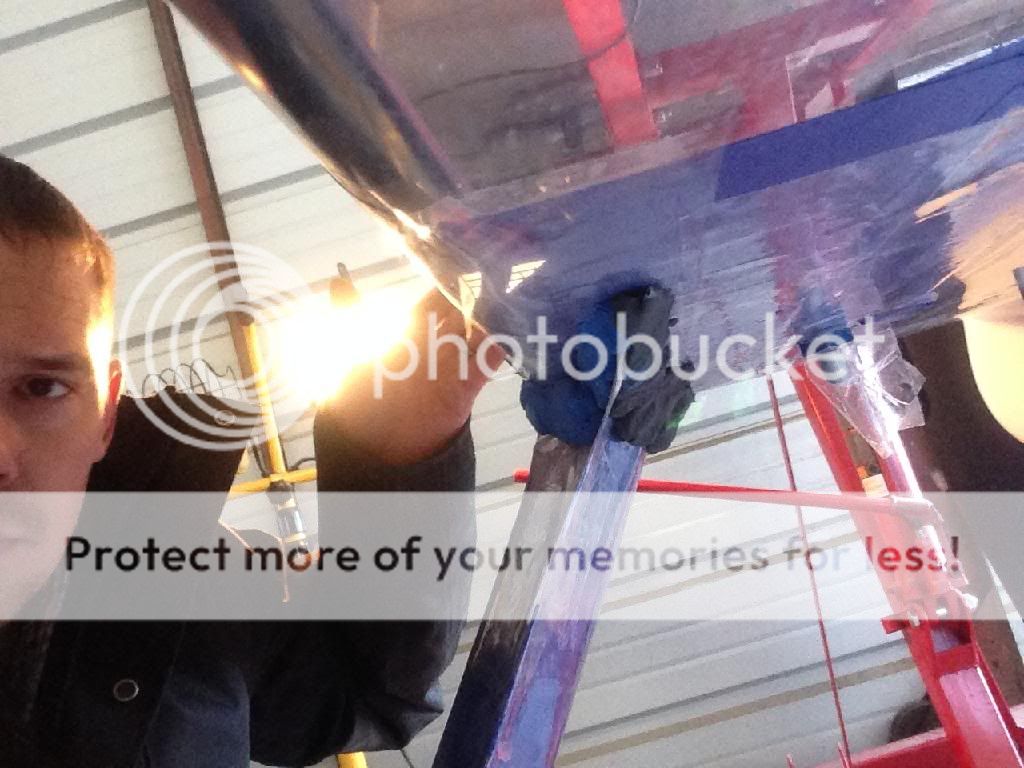

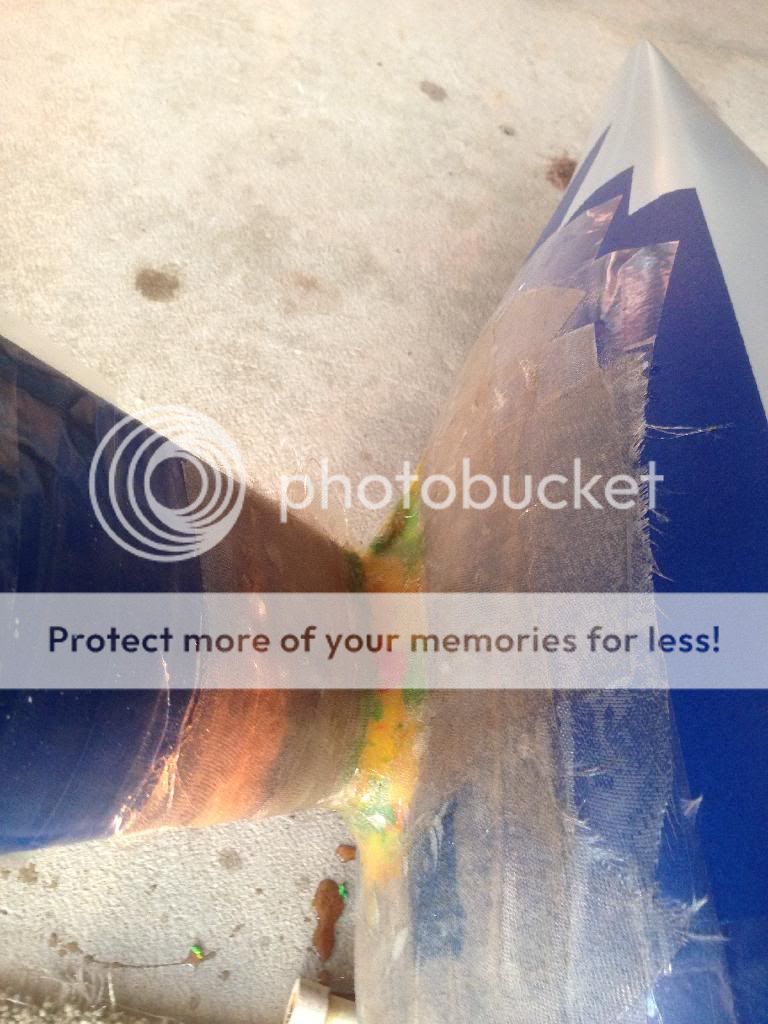

Basically I cut a construction paper template until it was close, used that to cut out some scrap .063 (it was about the same thickness of the fiberglass). Then I used the back of my vise (about the size of a beer can) and dead blow hammer to beat the curve into it. I basically beat it in two planes, one around the spinner back plate and one towards the pointy part of the spinner. Pretty easy overall, if it didn't fit right I just hit it harder!

Here's the only pics I found while I was making them.

Basically I cut a construction paper template until it was close, used that to cut out some scrap .063 (it was about the same thickness of the fiberglass). Then I used the back of my vise (about the size of a beer can) and dead blow hammer to beat the curve into it. I basically beat it in two planes, one around the spinner back plate and one towards the pointy part of the spinner. Pretty easy overall, if it didn't fit right I just hit it harder!

Last edited: