Kahuna

Moderatoring

8 years and ~2k hours of flying the Super 8 and its time for an engine overhaul. I have never experienced one of these (sold my RV-6A a few hundred hours before it was ready.)

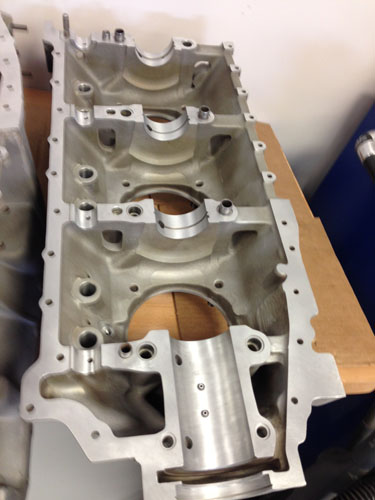

The engine has been very good to me and its only troubles over the years I have induced. I have become very attached to the reliability and performance of this IO-540. I picked up the motor from a shop in Florida back in the days where 540's were cheap. Certified and yellow tagged with accessories for $17,500. Those days are of course over, thank you Vans RV-10.

Those days are of course over, thank you Vans RV-10.

First few hundred hours were on 1LSE and one mag, then ~300 hours when the mag died, I went dual LSE.

My typically flight is all in to altitude then LOP 2300RPM to my destination so this engine has spent a vast majority of its time LOP. The other times is flying shows with the team ROP and a also a loafing RPM of 2300. CHT's have been kept below 400 generally unless I get on one of my hard altitude climbs to the FL's and I would generally see low 400's to 410 at worst. I have always felt I have treated the engine with respect. Compressions always in the mid 70s with the occasional mid 60 reading that would come back to mid 70's at the next check. Oil consumption was difficult to measure since I spend much of my time upside down with the neg g's tossing a bit even with the inverted oil. Long flights I would see about 1qt over 6 hours and was consistent over its life.

Reaching its 2k hour point, I felt it was time for an overhaul. The engine was not telling me it needed one. I was. The time is right for me during this off season. I can not afford an engine problem March - November.

Back in January I met Jimmy Brod (JB) in Sebring Fl at a show. JB and his dad have run an engine shop, JB Aircraft Services, there for decades. After just a few minutes of talking with JB, I decided that if I ever rebuilt my motor, this is the guy I want working on it. A quiet, humble, down to earth pair of father & son team. You all know how we are about our engines. I dont let anyone touch it that I don't trust my life with. And up until now, no one has touched it but me. I routinely take 'leap of faith' risks flying night ops over inhospitable terrain, hours over open water, IFR ops with no outs below. It has got to be reliable day in and day out.

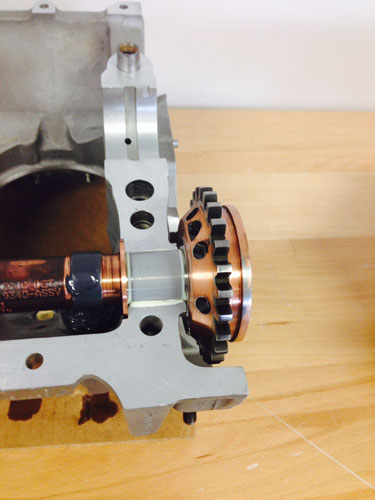

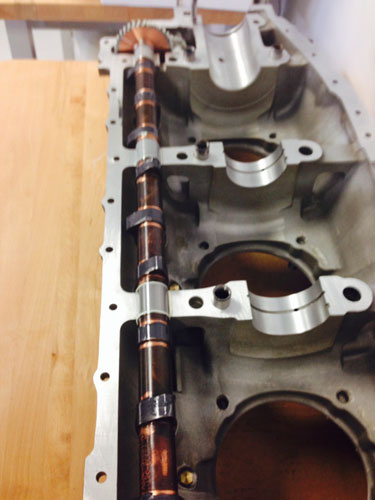

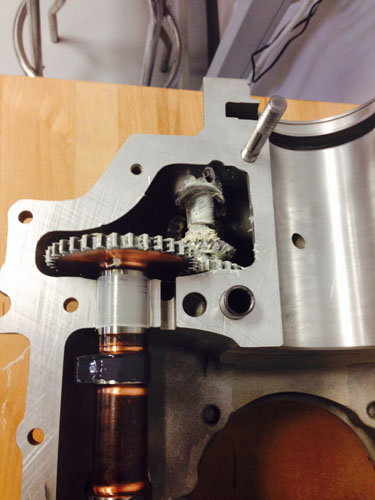

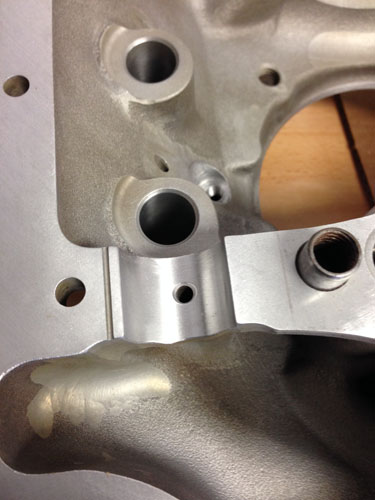

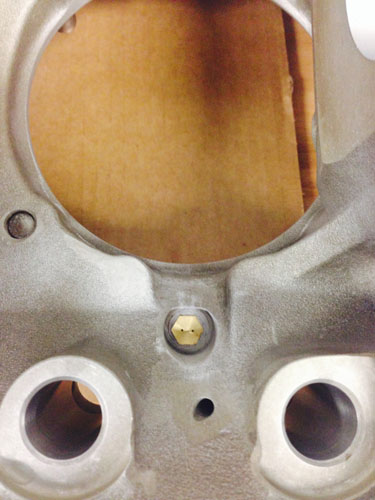

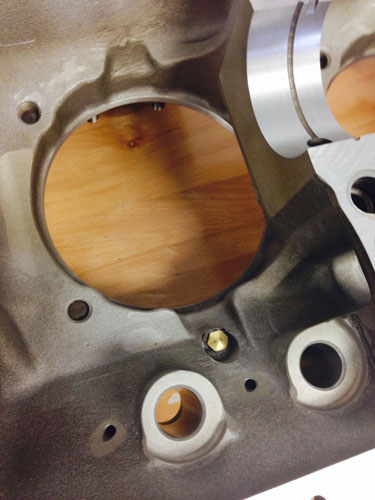

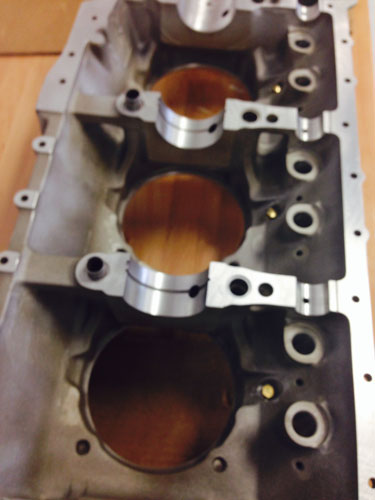

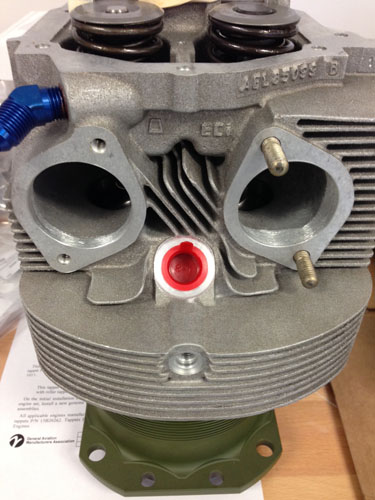

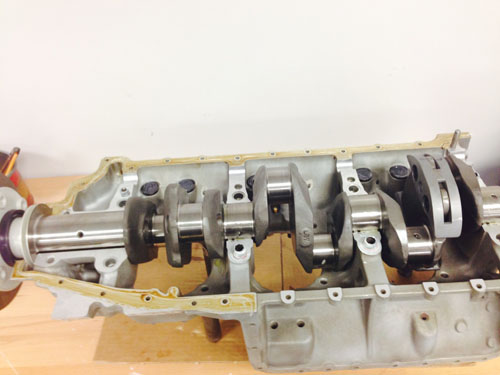

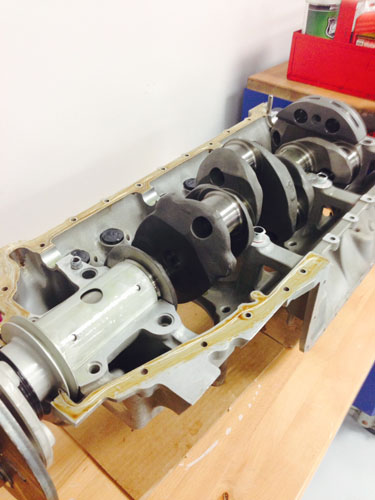

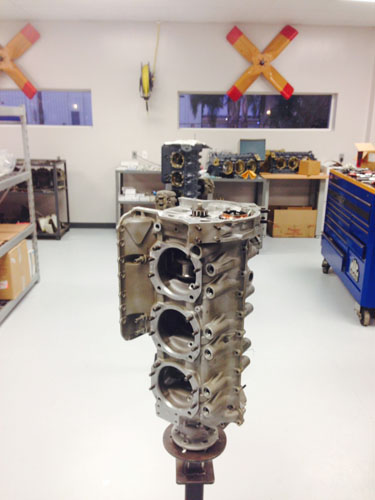

So off came the motor with the plan to have JB do the overhaul with mostly ECI parts. I have never gone through this process before. I thought I might document that here and report the findings.

Step one. Take lots of pictures so I can get things back to their respective places on reinstall.

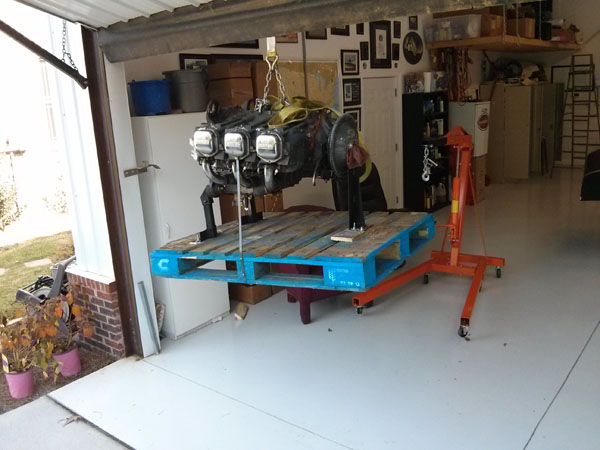

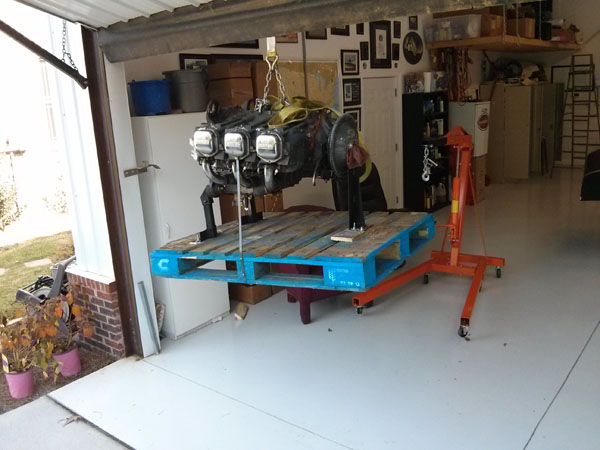

Step 2. Pull the motor. Time to pull single handed was 3 hours start to finished on pallet. I didnt break any records. This includes taking the time to tag everything. Here is the engine hanging from my bi-fold door ready to back up the pickup truck. Engine hoist is not tall enough to get this into my pickup truck.

Then truck it down to my local Yellow freight terminal to shipping to JB.

The engine has been very good to me and its only troubles over the years I have induced. I have become very attached to the reliability and performance of this IO-540. I picked up the motor from a shop in Florida back in the days where 540's were cheap. Certified and yellow tagged with accessories for $17,500.

First few hundred hours were on 1LSE and one mag, then ~300 hours when the mag died, I went dual LSE.

My typically flight is all in to altitude then LOP 2300RPM to my destination so this engine has spent a vast majority of its time LOP. The other times is flying shows with the team ROP and a also a loafing RPM of 2300. CHT's have been kept below 400 generally unless I get on one of my hard altitude climbs to the FL's and I would generally see low 400's to 410 at worst. I have always felt I have treated the engine with respect. Compressions always in the mid 70s with the occasional mid 60 reading that would come back to mid 70's at the next check. Oil consumption was difficult to measure since I spend much of my time upside down with the neg g's tossing a bit even with the inverted oil. Long flights I would see about 1qt over 6 hours and was consistent over its life.

Reaching its 2k hour point, I felt it was time for an overhaul. The engine was not telling me it needed one. I was. The time is right for me during this off season. I can not afford an engine problem March - November.

Back in January I met Jimmy Brod (JB) in Sebring Fl at a show. JB and his dad have run an engine shop, JB Aircraft Services, there for decades. After just a few minutes of talking with JB, I decided that if I ever rebuilt my motor, this is the guy I want working on it. A quiet, humble, down to earth pair of father & son team. You all know how we are about our engines. I dont let anyone touch it that I don't trust my life with. And up until now, no one has touched it but me. I routinely take 'leap of faith' risks flying night ops over inhospitable terrain, hours over open water, IFR ops with no outs below. It has got to be reliable day in and day out.

So off came the motor with the plan to have JB do the overhaul with mostly ECI parts. I have never gone through this process before. I thought I might document that here and report the findings.

Step one. Take lots of pictures so I can get things back to their respective places on reinstall.

Step 2. Pull the motor. Time to pull single handed was 3 hours start to finished on pallet. I didnt break any records. This includes taking the time to tag everything. Here is the engine hanging from my bi-fold door ready to back up the pickup truck. Engine hoist is not tall enough to get this into my pickup truck.

Then truck it down to my local Yellow freight terminal to shipping to JB.

Last edited: