Strike69

Active Member

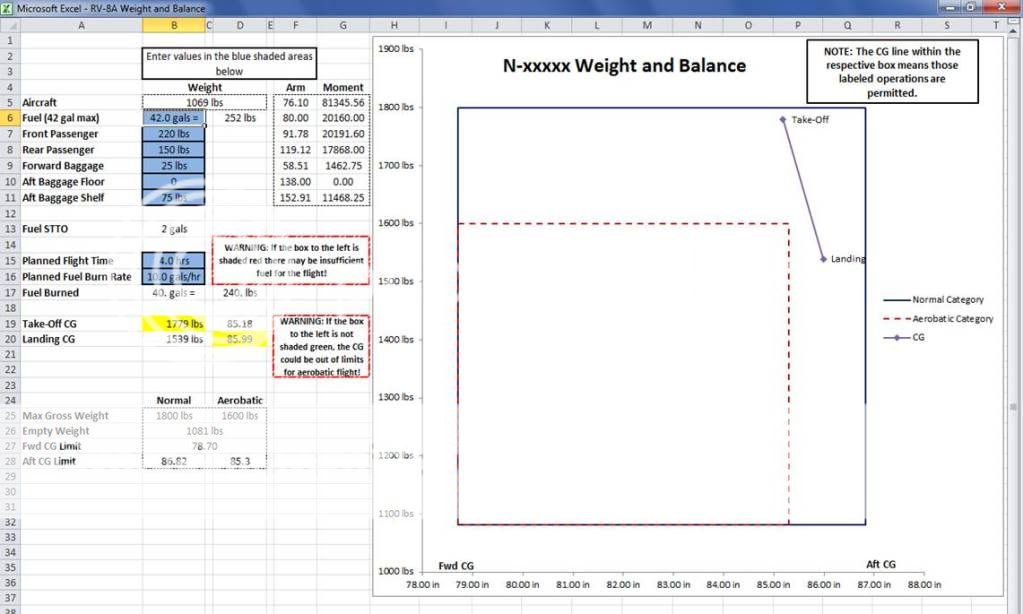

RV-8A #83243 N-251WM

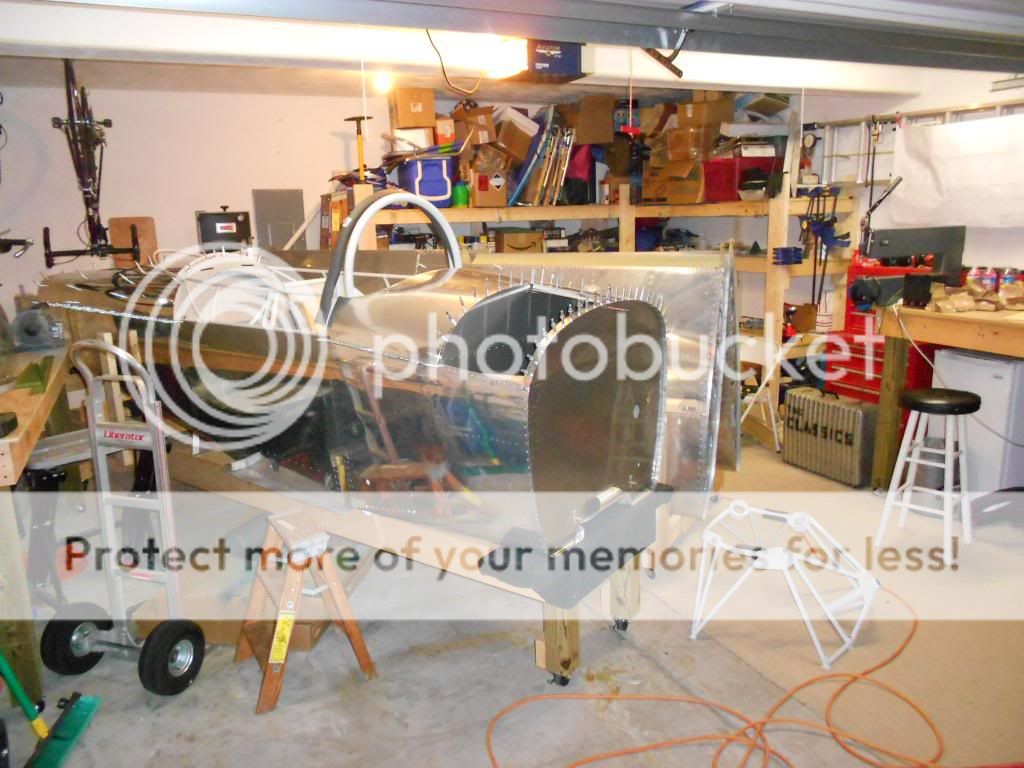

As my kids returned to their mother on Chirstmas Eve, I embarked on my journey of creating N-251WM (res). With all the ways to publish on the web, I think hosting the builds ON this site makes the most sense. I look forward to sharing my progress. Although I will providde updates here, I am still tracking my daily progress the old fashion way:

So far: 71 hrs since 12/24/11

Completed: Horizontal and vertical stabs (except for fiberglass) and parts for the elevators and rudder ready for priming.

Had to take a break when I realized the 1/2 car garage was not going to be big enough. Fortunately the lease was up and the landlord was selling. Now my new shop is set up and I'm ready to crank up the production again.

Now back to work ...

As my kids returned to their mother on Chirstmas Eve, I embarked on my journey of creating N-251WM (res). With all the ways to publish on the web, I think hosting the builds ON this site makes the most sense. I look forward to sharing my progress. Although I will providde updates here, I am still tracking my daily progress the old fashion way:

So far: 71 hrs since 12/24/11

Completed: Horizontal and vertical stabs (except for fiberglass) and parts for the elevators and rudder ready for priming.

Had to take a break when I realized the 1/2 car garage was not going to be big enough. Fortunately the lease was up and the landlord was selling. Now my new shop is set up and I'm ready to crank up the production again.

Now back to work ...

Last edited by a moderator: