Route... Well it was not direct.

Awesome overview. thanks. I'm registered for March classes.

What route did you take to get there and back?

Everyone else can skip over this - it has no technical merit.

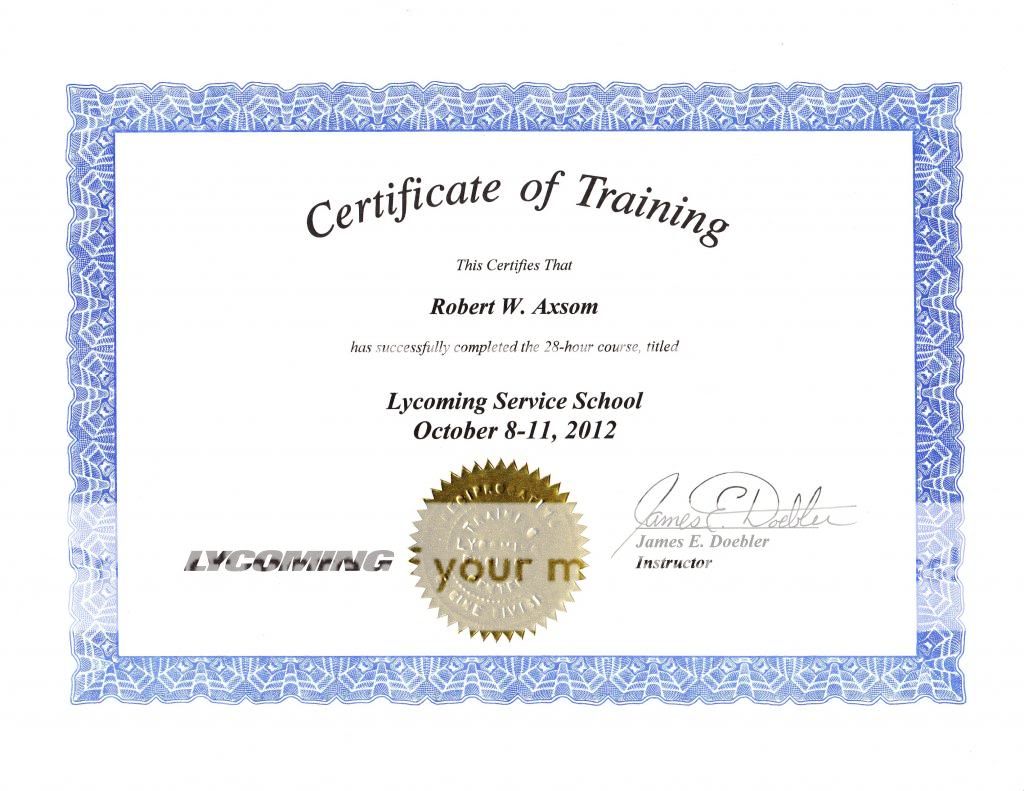

The classes are conducted in a series 8 times per year and the first class is 4 days long in a classroom but with a

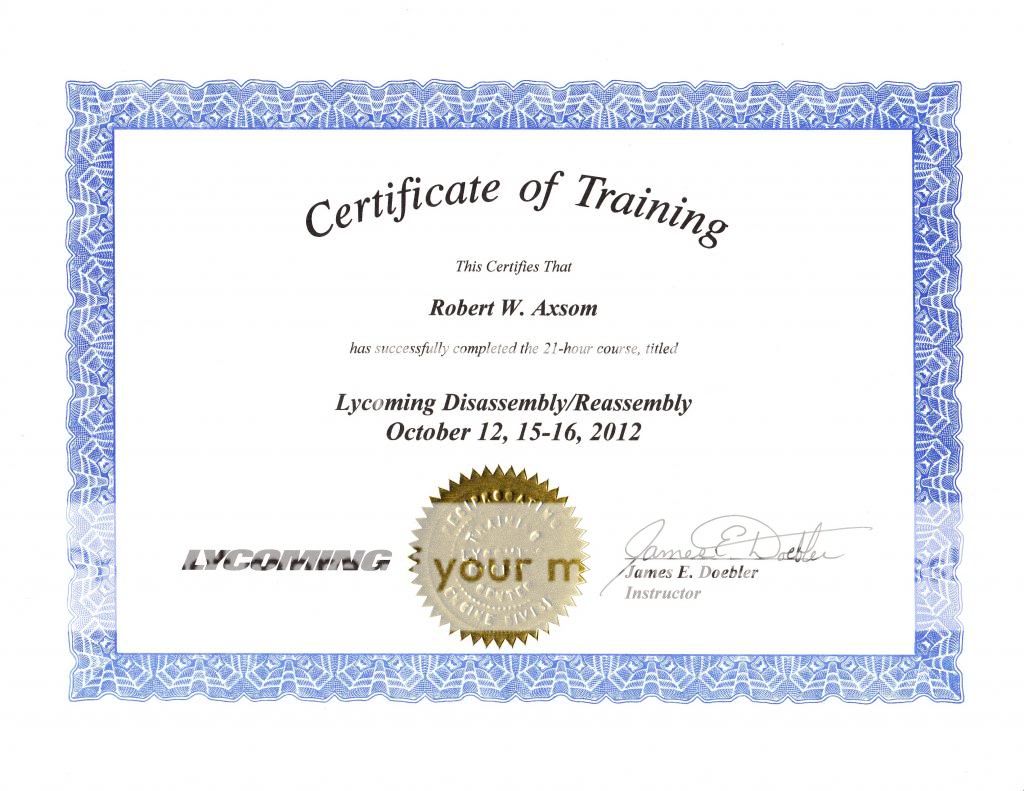

very experienced and open instructor and real hardware. It must be taken before you are allowed to take the Disassembly/Reassembly class which lasts 3 days but the classes may be taken with an unlimited time gap between the two.

I signed up for the classes at the earliest possible date (January 2013) and got on the waiting list for any cancellations. The first 4 day class (Lycoming Service School) opened up a few weeks ago beginning on October 8 and I got the call. You probably don't know it but I am also flying in every SARL race this year that is not in schedule conflict with another SARL race. There were two races scheduled on October 6 in Waupaca, WI and Galveston, TX and two more scheduled on October 13 in Cleveland, TX and Wickenburg, AZ. I had signed up for the Waupaca and Cleveland races. I saw right away that this would work and I took the opening in the Lycoming Service School class Class. I made my reservations for Waupaca, WI, Williamsport, PA and Cleveland Texas for rental cars and motels on October 1. I went to the SARL website and got the course information and went through the race preparation, looked at the general travel routes and ordered over $200 worth of sectional charts, Low altitude IFR charts and books of Terminal Procedures (approach plates) to fly from Fayetteville, Arkansas to Waupaca, Wisconsin on October 4, then continue to Willaimsport, Pensylvania after the race for the start of school on Monday Qctober 8 and then fly to Cleveland, Texas (just north of Houston) after the class let out on Thursday October 11. Comfortably tight but certainly doable. I was set and looking forward to it.

On October 2 a lady from the school called and said they had a cancelation for the Disassembly/Reassembly course beginning on Friday October 12 and completing on Monday and Tuesday October 15 and 16. She needed an answer so she could take care of filling the opening by continuing down the waiting list if necessary. I said I will take it.

I ran through the possible scenarios in my mind and concluded that I could enter the 10-6 race at Galvaston fly the plane to Cleveland, Texas, tie the plane down fueled up and ready to race, get a rental car and a room for the night in Cleveland, TX, get an early commercial flight to Williamsport on Sunday October 7 arriving early enough to get a few hours of sleep and be ready for class on Monday. Then On Friday evening I would fly commercially back to Houston pick up my rental car from the parking lot and drive back to Cleveland check back into my motel get a few hours of sleep then go to the airport early for final preps, briefing and the race. Then after the race I would fly the Blue Bird back to Williamsport check in to the motel get a few hours of sleep and be in class on Monday Oct. 15. It was definitely not comfortable but it seemed doable if the commercial flights worked out and the weather was adequate for my flying.

There are no direct flights between Williamsport and Houston. I cancelled my motel and car reservations at Waupaca and modified those at Cleveland and Williamsport. I got a two airplane flight to Harrisburg PA via DC and a rental car to drive to Williamsport and back and a two airplane flight to Houston via Charlotte, NC that made it possible. I would get back into Houston at midnight if everything worked as planned.

OK I won't give you the agonizing details but for the actual route I flew south over Fort Smith, Texarkana, Lufkin following Victor Airways on an IFR flight plan and in solid IMC (I love TruTrak) starting 300 ft above the runway at Fayetteville's Drake Field (FYV). At Lufkin the clouds started breaking up and the controller offered direct to Cleveland. I got there got the rental car (truck actually - it was Texas after all) parked it at the airport with all of my unessential race baggage, put 10 gallons of Fuel in each tank (I wanted to show good faith at Galveston by buying fuel) and flew to Galveston for the next morning's race. I do not have lights in race configuration but I got there early enough to start a test run around the course (which was very beneficial). After turn 9 I had one red light come on for low fuel so I could see turn 10 at an outlet to the Gulf and no reason for doing anything but switching to the other tank and heading for the airport. Everything went well there and after the race I flew to Cleveland without landing. I made a telephone call for wakeup at 0300 but it never came. I woke up on my own somewhere between 4 and 5 am threw some clothes in a bag and raced to the Bush airport without the usual morning brush, shave and shower. I made it on the flight, the transfer, and drive to Williamsport.

When class let out on Friday I reversed the drive to Harrisburg and caught the flight with transfer to Houston. I got to bed between 2 and 3 am and after a few hours of sleep went to the airport installed the fresh air vent covers and removed the two Nav antenna elements, attended the briefing and flew the race. After the race I was delayed in getting to the fuel pump by the ramp marshals so I removed the fresh air vent covers, reinstalled my Nav antenna elements transfered all of my baggage from the truck to the plane while waiting. After refueling I got a weather/TFR briefing on the phone and planned to fly as direct as VFR weather would allow with a forecast 40 kt wind blowing direct from Cleveland to Williamsport - somebody was in my corner. I started out higher over Tennessee I could see a broken layer below that didn't have a visible end. A quick check with flight watch on 122.0 confirmed my suspicion and I went down to 3,500 and continued on. Abeam London, Kentucky I could see darkening skies ahead extending down to the mountains of Kentucky and West Virginia. I did not have a convenient "out" in that direction so I turned to London and remained over night. I felt wide awake and razor sharp but when I finally laid down after eating dinner at Frisch's Big Boy with nothing but peanut butter & cheese crackers in flight all day I slept a straight 10 hours. I called for a weather briefing Sunday morning and I was told visual conditions existed all the way to my destination so I cut the briefing short and got in the air as soon as possible. It was a nonstop VFR flight the rest of the way with overcast but not threateningly so.

To be continued

Bob Axsom