Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tip: Fiberglass Fabrication

- Thread starter DanH

- Start date

Chris Hill

Well Known Member

Thanks. Fiberglassing an 8 (gear legs and tail ) to finish up for painting

islandmonkey

Well Known Member

There is so much good information in this thread, many thanks Dan. I propose that this should be made a sticky. How about it mods?

Geico266

Well Known Member

Anyone working on fiberglass now or in the future should benchmark this thread. I have referred to it dozens of times to refresh my feeble mind on how to kill pin holes and help people with the RV-12 canopy.

With over 14,000 hits I sure am not the only one referring to this thread several times. I vote for a sticky designation or a technical forum and this be placed at the top for fiberglass.

Thanks Dan.

With over 14,000 hits I sure am not the only one referring to this thread several times. I vote for a sticky designation or a technical forum and this be placed at the top for fiberglass.

Thanks Dan.

rocketbob

Well Known Member

Just want to add to this thread. Over the last few months I have switched over to doing all of my layups with carbon fiber. Much stronger, lighter, wets out better, and generally is easier to work with than fiberglass. More expensive, but if your time is worth anything, you'll find that it isn't all that much more expensive.

I get my carbon supplies from a local supplier that does phone orders. www.avtcomposites.com They are very knowledgeable and their prices beat hands-down the major homebuilder suppliers. On carbon fiber cloth their prices are nearly half as much.

I get my carbon supplies from a local supplier that does phone orders. www.avtcomposites.com They are very knowledgeable and their prices beat hands-down the major homebuilder suppliers. On carbon fiber cloth their prices are nearly half as much.

broken1234

Active Member

One caution with carbon fiber... if you are new to composite work, learn with glass so you can see your air bubbles. My experience training in composites has shown that most people with no prior glass experience leave much more trapped air, and their layups are usually wetter (meaning heavier than necessary.)

Brad Simmons

Airframes Inc.

Milan, TN

Brad Simmons

Airframes Inc.

Milan, TN

Urethane foam

I finally decided to try the urethane foam DanH recommended at the beginning of this thread, and it works great! I've always used pink insulation foam for making plugs, but I think I'm a changed man.

The 4oz foam is significantly lighter than the insulation-in-a-can stuff you buy at the hardware store, but it's a really good balance of "sandability" and durability.

In cases where some of the foam will be permanently encased in the layup, I think it would be a good idea to scrape a layer of dry micro into the surface of the urethane foam before the first layer of cloth. Otherwise, I think the foam would soak up a lot of heavy epoxy resin into the pores exposed during sanding, and introduce bubbles into the layup. But I tend to make stuff complicated.

Thanks for the tip, Dan!

M

I finally decided to try the urethane foam DanH recommended at the beginning of this thread, and it works great! I've always used pink insulation foam for making plugs, but I think I'm a changed man.

The 4oz foam is significantly lighter than the insulation-in-a-can stuff you buy at the hardware store, but it's a really good balance of "sandability" and durability.

In cases where some of the foam will be permanently encased in the layup, I think it would be a good idea to scrape a layer of dry micro into the surface of the urethane foam before the first layer of cloth. Otherwise, I think the foam would soak up a lot of heavy epoxy resin into the pores exposed during sanding, and introduce bubbles into the layup. But I tend to make stuff complicated.

Thanks for the tip, Dan!

M

Polyester high build primers or glazing putty??

Dan et al,

A pilot friend has a body shop and mostly uses polyester primer and polyester putty/glazing compound (ACS has one called "Prestec Polyester Sanding Primer" http://www.aircraftspruce.com/catalog/cspages/hibuildPrimers.php).

So I primed some fiberglass parts (destined for inside the cowling with my Subaru) with DP40 per your examples above. Of course this revealed a few pinholes and other imperfections. I was needing some training in spraygun technique so took the primed airfilter box to his shop where we applied 5 coats of his polyester high build primer (probably PPG). It sanded out beautifully with most of the pinholes filled.

I think the main reason he was using the polyester primer was cost when compared to the PPG K36. He still wants me to apply a couple of coats of the K36 before painting with a single stage two part PPG paint.

I could not find any reference to anything "polyester" in all your writings. What sayest thou oh wise sage?

Oh yeah, when the micro on the outside of the part seemed like it would take way too long to finish I also used some Marson "Platinum Premium Lightweight Filler" to prep the part for the DP40. All I could see that you used was micro. (Maybe I just did not put enough micro on so all the prep work could be accomplised with one application?) What about the few pinholes you did have? How did you fill those few remaining holdouts?

So my part has these "layers" at this time: fiberglass, micro and body filler, DP40, and a few pinholes left to fill. Next would be the K36 and single stage paint finish. What SHOULD be the sequence for the future?

Hope this is not too confusing.

Dan et al,

A pilot friend has a body shop and mostly uses polyester primer and polyester putty/glazing compound (ACS has one called "Prestec Polyester Sanding Primer" http://www.aircraftspruce.com/catalog/cspages/hibuildPrimers.php).

So I primed some fiberglass parts (destined for inside the cowling with my Subaru) with DP40 per your examples above. Of course this revealed a few pinholes and other imperfections. I was needing some training in spraygun technique so took the primed airfilter box to his shop where we applied 5 coats of his polyester high build primer (probably PPG). It sanded out beautifully with most of the pinholes filled.

I think the main reason he was using the polyester primer was cost when compared to the PPG K36. He still wants me to apply a couple of coats of the K36 before painting with a single stage two part PPG paint.

I could not find any reference to anything "polyester" in all your writings. What sayest thou oh wise sage?

Oh yeah, when the micro on the outside of the part seemed like it would take way too long to finish I also used some Marson "Platinum Premium Lightweight Filler" to prep the part for the DP40. All I could see that you used was micro. (Maybe I just did not put enough micro on so all the prep work could be accomplised with one application?) What about the few pinholes you did have? How did you fill those few remaining holdouts?

So my part has these "layers" at this time: fiberglass, micro and body filler, DP40, and a few pinholes left to fill. Next would be the K36 and single stage paint finish. What SHOULD be the sequence for the future?

Hope this is not too confusing.

I could not find any reference to anything "polyester" in all your writings. What sayest thou oh wise sage?

It's like that E6Ti...it's generally found in old used cars.

Last edited:

az_gila

Well Known Member

It's like that E6Ti...it's generally found in old used cars.

Dan.. the Prestec polyester primer is used in sailplane refinishing and followed up with Prestec polyester paint.

It does seem to be the exception about using polyester over epoxy, but has been well proven over several decades on German sailplanes.

The Prestec paint does not yellow like some of the German factory sailplane finishes.

The company nmae is actually Simtec and they are a small outfit in the LA basin area, sort of near Aircraft Spruce. They were very easy to deal with directly.

http://www.simteccoatings.com/Productlist.ivnu

And Allen also asked:

"What about the few pinholes you did have? How did you fill those few remaining holdouts?" Polyester is out so what to use?

No, polyester is not out. As I've written before, polyester filler has three uses in my own shop.

(1) Fast touch up of minor defects discovered after the first spray coat of epoxy primer. Press some mixed fiiller into a pinhole, then come back in 15 minutes and sand off every trace except what remains down in the hole. It's not a pinhole filling proceedure. It's a quick save when I did a poor job with previous work and later find a renegade pinhole or chip after shooting the first coat of epoxy primer.

(2) Fairing wood wing surfaces under fabric.

(3) Jigs and fixtures.

Polyester primer? Years ago (early 90s) my body shop professional shot a good grade of polyester primer-surfacer on my glass/epoxy project, followed by a two-part single stage white. In about three years it started peeling. Next time you come by the hangar I'll show you.

What would you use to transition the overhead console to the rest of the cabin top?

Sorry Jim, missed your post.

This is a right angle joint? The traditional way is a wiped-in filet of flox/epoxy mix followed by glass fabric before the flox cures. Use the round end of a tongue depressor to make the filet radius consistent along the joint length. The fabric will lay in a smaller radius if cut on the bias. Don't use glass tape unless you're willing to sand away the thick selvage edges later. Cut fabric (for thin edges) covered with soaked peel ply is more or less self-fairing and needs little subsequent filler for finishing (see post 41). I use dry micro for all fairing and finishing.

Last edited:

Do you recommend and howto videos? Or ever thought on making any?

No and **** no.

Buy this kit:

http://www.aircraftspruce.com/builderkits.php?PN=01-15000

Read Moldless Composite Homebuilt Sandwich Aircraft Construction a few times (included in the kit). It's a better instructional piece than any current book or video.

Actually build the three practice exercises.

Then build airplane parts.

More general fabrication. The task is to duplicate an existing cowling outlet panel, with a 4" extension. Later this panel will be modified to incorporate a variable exit.

The job needs a female mold. This example uses a quick-'n-dirty mold made with materials at hand.

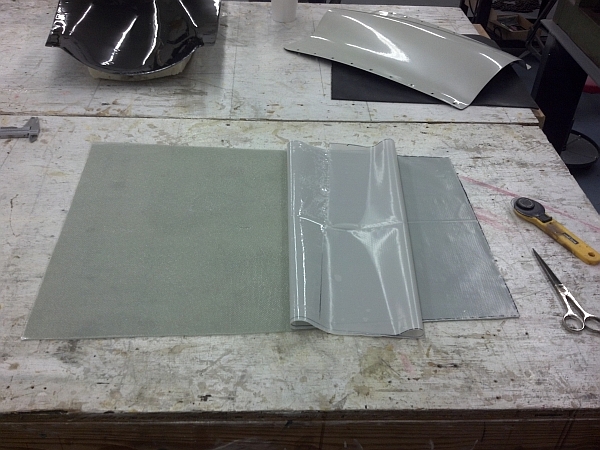

Started by cobbling up an extension, as the need panel needs to extend aft of the firewall. It was simply taped to the existing panel. The existing panel is slick (finish painted base and clear), so all it needs is two coats of PVA to make it non-stick. After the PVA cures, lay up two plies of plain 9oz to make the female mold. Plain weave is fine as there are no significant compound curves.

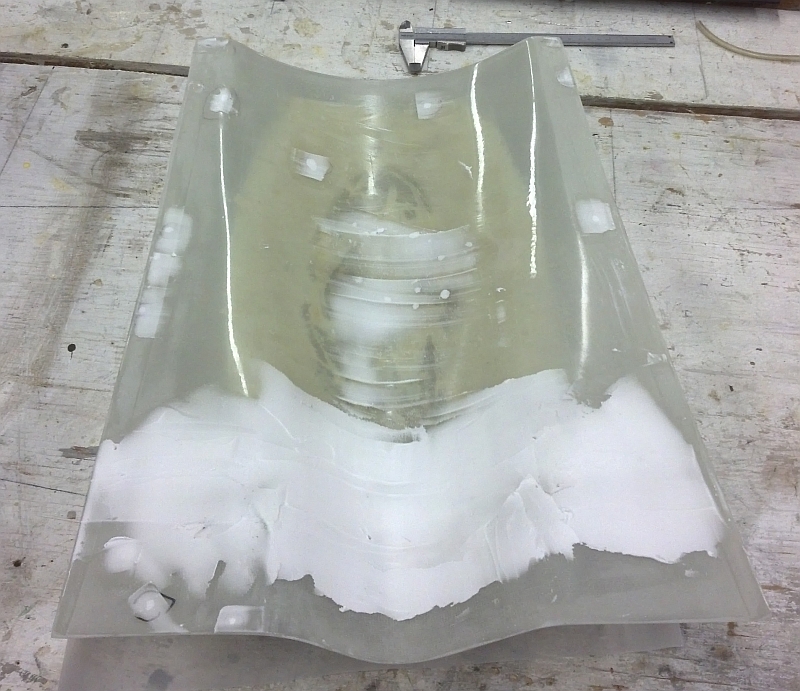

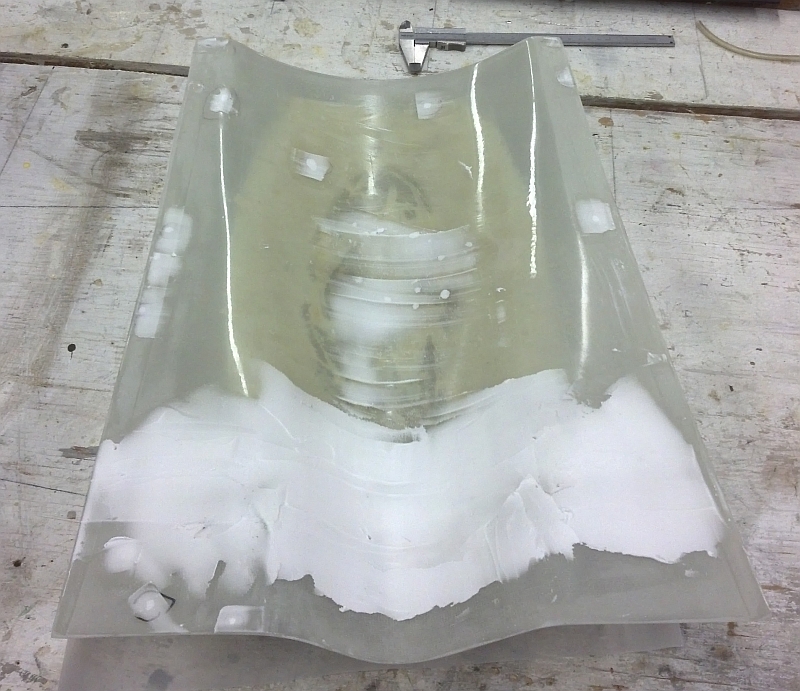

After cure separate the mold from the part with an air hose. The stuff which looks like plastic wrap is the PVA film blown loose.

In this case the mold panel isn't perfect. The taped seam between the original part and the extension needs some fairing, and there are a few air bubble voids to fill. So, scuff off the high spots with 80 grit.....

....wipe in some micro, and come back tomorrow.

The job needs a female mold. This example uses a quick-'n-dirty mold made with materials at hand.

Started by cobbling up an extension, as the need panel needs to extend aft of the firewall. It was simply taped to the existing panel. The existing panel is slick (finish painted base and clear), so all it needs is two coats of PVA to make it non-stick. After the PVA cures, lay up two plies of plain 9oz to make the female mold. Plain weave is fine as there are no significant compound curves.

After cure separate the mold from the part with an air hose. The stuff which looks like plastic wrap is the PVA film blown loose.

In this case the mold panel isn't perfect. The taped seam between the original part and the extension needs some fairing, and there are a few air bubble voids to fill. So, scuff off the high spots with 80 grit.....

....wipe in some micro, and come back tomorrow.

Last edited:

Sand the cured micro as necessary for shape, wipe in neat epoxy to seal and fill pinholes. Finish up with a cheap nappy roller to leave an orange peel finish, a good sanding guide.

Allow epoxy cure, sand it slick, shoot it with a black spray can. Whatever you have on the shelf is fine. When the paint cures shoot it with two coats of PVA.

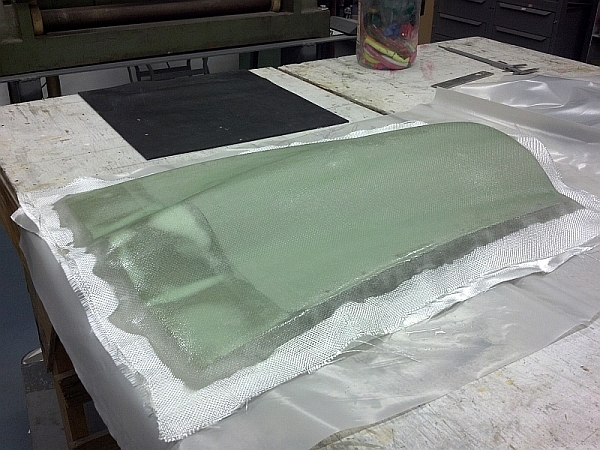

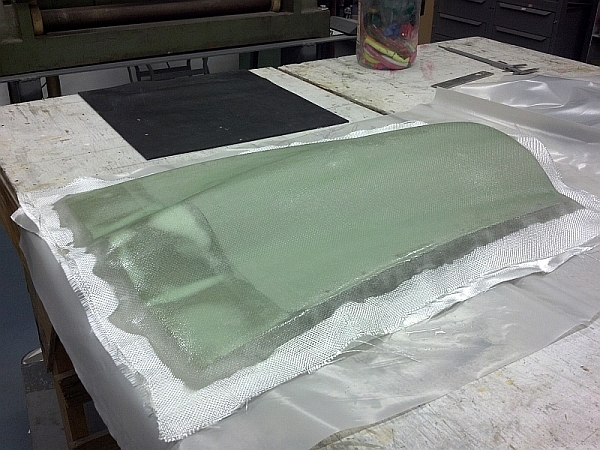

Lay out plastic sheet and stack up precut glass cloth as required. Mix resin, dump it on, add a top plastic sheet, and roll the resin into the cloth. Roll air and excess resin to the edges until you have a nice consolidated layup.

Trim to the correct size to cover the mold plus a little bit. Cut right through the plastic cover sheets. Peel the top sheet, flip the layup, and lay it on the mold.

Peel the other plastic sheet. Use a roller and a brush to smooth the layup into the mold, working out all air. The air is easy to see because you painted the mold a dark color. Add peel ply if you intend to bond to the part later. Peel ply saves sanding time as it leaves a nice fractured finish suitable for bonding with little prep. In this case I also added a strip of scrap cloth over the peel ply, down in the concave belly of the part. Epoxy tends to flow a bit initially, and would make the low spot overly wet. The scrap cloth soaks up any excess resin and tears off with the peel ply.

In the morning it is Happy Feet time.....rip off the peel ply and pop the part out of the mold. Wear gloves to handle the part until trimmed, as the glass needles along the untrimmed edges will really stick you. Trim the edges on the bandsaw and sand them straight with 80 grit on a 18"x3" sanding block.

As removed from the mold the surface finish is much like the wheelpants you get from Vans. No surprise. Subsequent finish steps to prepare for paint will be the same.

More later.

Allow epoxy cure, sand it slick, shoot it with a black spray can. Whatever you have on the shelf is fine. When the paint cures shoot it with two coats of PVA.

Lay out plastic sheet and stack up precut glass cloth as required. Mix resin, dump it on, add a top plastic sheet, and roll the resin into the cloth. Roll air and excess resin to the edges until you have a nice consolidated layup.

Trim to the correct size to cover the mold plus a little bit. Cut right through the plastic cover sheets. Peel the top sheet, flip the layup, and lay it on the mold.

Peel the other plastic sheet. Use a roller and a brush to smooth the layup into the mold, working out all air. The air is easy to see because you painted the mold a dark color. Add peel ply if you intend to bond to the part later. Peel ply saves sanding time as it leaves a nice fractured finish suitable for bonding with little prep. In this case I also added a strip of scrap cloth over the peel ply, down in the concave belly of the part. Epoxy tends to flow a bit initially, and would make the low spot overly wet. The scrap cloth soaks up any excess resin and tears off with the peel ply.

In the morning it is Happy Feet time.....rip off the peel ply and pop the part out of the mold. Wear gloves to handle the part until trimmed, as the glass needles along the untrimmed edges will really stick you. Trim the edges on the bandsaw and sand them straight with 80 grit on a 18"x3" sanding block.

As removed from the mold the surface finish is much like the wheelpants you get from Vans. No surprise. Subsequent finish steps to prepare for paint will be the same.

More later.

Last edited:

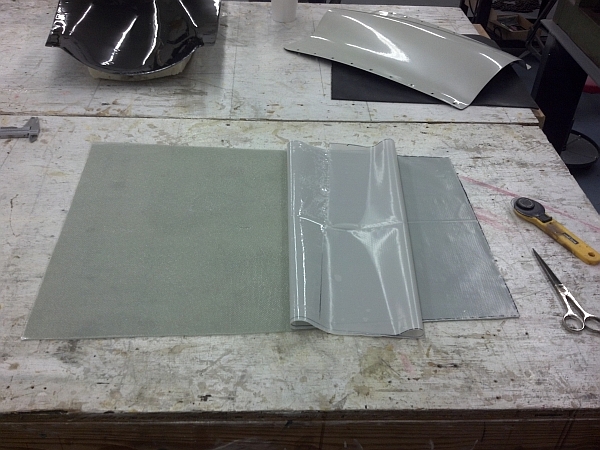

Re-creating a belly blister for a certain yellow airplane. I have no idea how a skinny kid named Dick made the first one back in the 1960's, but it was my honor to make the second.

Start with a profile in dense block foam....

....then shape to contour....

....glue to a base, add a filet, and paint the whole thing with some epoxy.

Sand slick, spray some high build primer from a squirt can, sand again...

...shoot with some gloss black, then some PVA.

Start with a profile in dense block foam....

....then shape to contour....

....glue to a base, add a filet, and paint the whole thing with some epoxy.

Sand slick, spray some high build primer from a squirt can, sand again...

...shoot with some gloss black, then some PVA.

Last edited:

The layup is 8.9oz 8-harness satin, because it drapes so nice over compound curves. A strip of tape thickened the flange where rivets would go later.

Time to cure, a little trimming, and gee, ain't it pretty?

Now if I can just talk them into hanging the airplane from the ceiling, I can see it when I visit the museum.

(Postscript...they did!)

Time to cure, a little trimming, and gee, ain't it pretty?

Now if I can just talk them into hanging the airplane from the ceiling, I can see it when I visit the museum.

(Postscript...they did!)

Last edited:

Nice layup job. I see two wings in one picture. What are they from?

One-offs built by an old friend. I've been reducing them to cad drawings for structural analysis, after which a decision can be made about best use. Leading candidate is a Breezy.

Yes, all the ribs were hammered out on steel forms.

Last edited:

rv7boy

Forum Peruser

NEWSFLASH!

An Aircraft Spruce employee who works online sales wonders why 285 orders for Part No. 01-15000 arrived in one morning!

VAF readers know why.

No and **** no.

Buy this kit:

http://www.aircraftspruce.com/builderkits.php?PN=01-15000

Read Moldless Composite Homebuilt Sandwich Aircraft Construction a few times (included in the kit). It's a better instructional piece than any current book or video.

Actually build the three practice exercises.

Then build airplane parts.

An Aircraft Spruce employee who works online sales wonders why 285 orders for Part No. 01-15000 arrived in one morning!

VAF readers know why.

nappy rollers

Dan, backing up this thread a bit, I'm curious which cheap nappy roller brand you've been using. I've tried a couple of brands from the local hardware/paint/bigbox stores, and found that they shed fibers badly into the wet epoxy. After recoiling in horror the first time I tried one (on my lower cowl) I was more cautious and tried a different one on a test case. Same result. Nasty mess of fibers left on the surface, so I reverted to using the 3 layers squeegeed method. Bummer, because I really like the idea of the roller...

Dan, backing up this thread a bit, I'm curious which cheap nappy roller brand you've been using. I've tried a couple of brands from the local hardware/paint/bigbox stores, and found that they shed fibers badly into the wet epoxy. After recoiling in horror the first time I tried one (on my lower cowl) I was more cautious and tried a different one on a test case. Same result. Nasty mess of fibers left on the surface, so I reverted to using the 3 layers squeegeed method. Bummer, because I really like the idea of the roller...

I'm curious which cheap nappy roller brand you've been using. I've tried a couple of brands from the local hardware/paint/bigbox stores, and found that they shed fibers badly into the wet epoxy. .

Cheapest thing on the shelf at the big box store. Have not noticed fiber shedding. Sure seems like they would shed into paint too.

Heck, experiment! Try a foam roller.

How did you get the tear-drop blister so well shaped?

Eyeball. Simple shapes are not a difficult as you may think.

So help me

This is a very informative thread. Some of the items seems clear to all but me. Maybe simply language issue. So here are a few questions that confuses me.

1. Dan writes "cut on bias" I have no idea what that cut looks like.

2. Dan mentions "dry micro". I know about micro balloons which is mostly a filler when mixed with epoxy. Not structural, only for cosmetic/finishing use. Don't know what the "dry" means. Powder only? Thick mixture?

3. PVA. I know PVA as a paint, mostly house paint. Do you get this in a rattle can? Only applied with spray gun? Brush on? Once applied to a mold, does it stay there as a releasing agent forever? Does it have to be re-applied each tine you use the mold? Is it clear or color or either or does not matter?

4. Flox Fillet. I've sort of figured this out to mean forming a radius at a right angle joint to assist with application of FG sheet at later stage. Is this correct? Then Dan also talks about a "Fillet layup". Not sure what this means. Where does the Flox get into the picture? (For the most part a "fillet" is a nice cut of meat!!)

5. Dan talks about "Applying fabric". Does this refer to woven FG, or is it something like ceconite/dacron or some other type of fabric?

6. Wax. I have the Sam James CD and he talks about applying wax to prevent the epoxy from sticking. What kind of wax is this? Same what women uses? Bees wax? Wax polish for shining a car? Liquid or paste form? After application do you have to "shine" it like car polish to work as releasing layer?

7. Does Epoxy stick to electrical insulation tape? Do you need to apply wax or some other form of releasing layer?

See my confusion?

Thanks.

Johan

This is a very informative thread. Some of the items seems clear to all but me. Maybe simply language issue. So here are a few questions that confuses me.

1. Dan writes "cut on bias" I have no idea what that cut looks like.

2. Dan mentions "dry micro". I know about micro balloons which is mostly a filler when mixed with epoxy. Not structural, only for cosmetic/finishing use. Don't know what the "dry" means. Powder only? Thick mixture?

3. PVA. I know PVA as a paint, mostly house paint. Do you get this in a rattle can? Only applied with spray gun? Brush on? Once applied to a mold, does it stay there as a releasing agent forever? Does it have to be re-applied each tine you use the mold? Is it clear or color or either or does not matter?

4. Flox Fillet. I've sort of figured this out to mean forming a radius at a right angle joint to assist with application of FG sheet at later stage. Is this correct? Then Dan also talks about a "Fillet layup". Not sure what this means. Where does the Flox get into the picture? (For the most part a "fillet" is a nice cut of meat!!)

5. Dan talks about "Applying fabric". Does this refer to woven FG, or is it something like ceconite/dacron or some other type of fabric?

6. Wax. I have the Sam James CD and he talks about applying wax to prevent the epoxy from sticking. What kind of wax is this? Same what women uses? Bees wax? Wax polish for shining a car? Liquid or paste form? After application do you have to "shine" it like car polish to work as releasing layer?

7. Does Epoxy stick to electrical insulation tape? Do you need to apply wax or some other form of releasing layer?

See my confusion?

Thanks.

Johan

Cheapest thing on the shelf at the big box store. Have not noticed fiber shedding. Sure seems like they would shed into paint too.

Heck, experiment! Try a foam roller.

Experiment. Yessirree, that I will do. Have not seen foam rollers in this part of the world, but next time I take on glass work I will go looking for them. And yeah, hard to imagine selling rollers that shed. The epoxy I spread with the rollers was a long way from kicking, so that wasn't the issue.

See attempted answers within...

This is a very informative thread. Some of the items seems clear to all but me. Maybe simply language issue. So here are a few questions that confuses me.

1. Dan writes "cut on bias" I have no idea what that cut looks like.

See explanation here: http://en.wikipedia.org/wiki/Bias_(textile)

2. Dan mentions "dry micro". I know about micro balloons which is mostly a filler when mixed with epoxy. Not structural, only for cosmetic/finishing use. Don't know what the "dry" means. Powder only? Thick mixture?

Thick mixture. Blend in enough microballoons that the mixture stops flowing. Then add some more.

3. PVA. I know PVA as a paint, mostly house paint. Do you get this in a rattle can? Only applied with spray gun? Brush on? Once applied to a mold, does it stay there as a releasing agent forever? Does it have to be re-applied each tine you use the mold? Is it clear or color or either or does not matter?

Poly Vinyl Acetate. Release agent. Needs to be re-applied every time. Water-soluble. Clear to bluish in color. I've always bought it in liquid form, then sprayed on with a cheap cup gun.

4. Flox Fillet. I've sort of figured this out to mean forming a radius at a right angle joint to assist with application of FG sheet at later stage. Is this correct? Then Dan also talks about a "Fillet layup". Not sure what this means. Where does the Flox get into the picture? (For the most part a "fillet" is a nice cut of meat!!)

A nice cut of meat is a filetFillet is where parts meet at a 90 degree (more or less) angle. Unlike micro, flox is structurally strong. Since fabric has a difficult time getting into a sharp corner, mix epoxy and flox, then use your finger (or at least I use my finger) to lay the mixture into the corner to create a fillet.

5. Dan talks about "Applying fabric". Does this refer to woven FG, or is it something like ceconite/dacron or some other type of fabric?

Fiberglass cloth. Lots of flavors available. Some lay over compound curves better than others. Much information about that on this site.

6. Wax. I have the Sam James CD and he talks about applying wax to prevent the epoxy from sticking. What kind of wax is this? Same what women uses? Bees wax? Wax polish for shining a car? Liquid or paste form? After application do you have to "shine" it like car polish to work as releasing layer?

Mold release wax. Looks/smells like carnauba paste wax. Optimized for mold release purposes. Aircraft Spruce sells it, among other vendors.

7. Does Epoxy stick to electrical insulation tape? Do you need to apply wax or some other form of releasing layer?

I've had mixed results. Have had epoxy stick vigorously along the edge of electrical tape where the adhesive is exposed. But not always. I use Scotch brand tapes exclusively, as they seem better behaved. These days if I'm applying epoxy over electrical tape I apply mold release wax first.

See my confusion?

Thanks.

Johan

CarlosF@grtavionics

Active Member

The Answer(s) to your questions

Moldless Composite Sandwich Aircraft Construction by Burt Rutan

http://www.amazon.com/Moldless-Composite-Sandwich-Aircraft-Construction/dp/B000BUJP5A

Easy read and everything you need to know to make parts like this assembly.

Bigger picture

Carlos Fernandez

Avionics guy with interest in composites.

Moldless Composite Sandwich Aircraft Construction by Burt Rutan

http://www.amazon.com/Moldless-Composite-Sandwich-Aircraft-Construction/dp/B000BUJP5A

Easy read and everything you need to know to make parts like this assembly.

Bigger picture

Carlos Fernandez

Avionics guy with interest in composites.

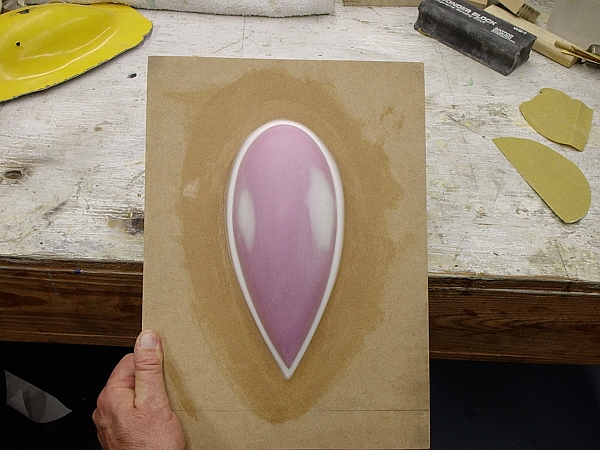

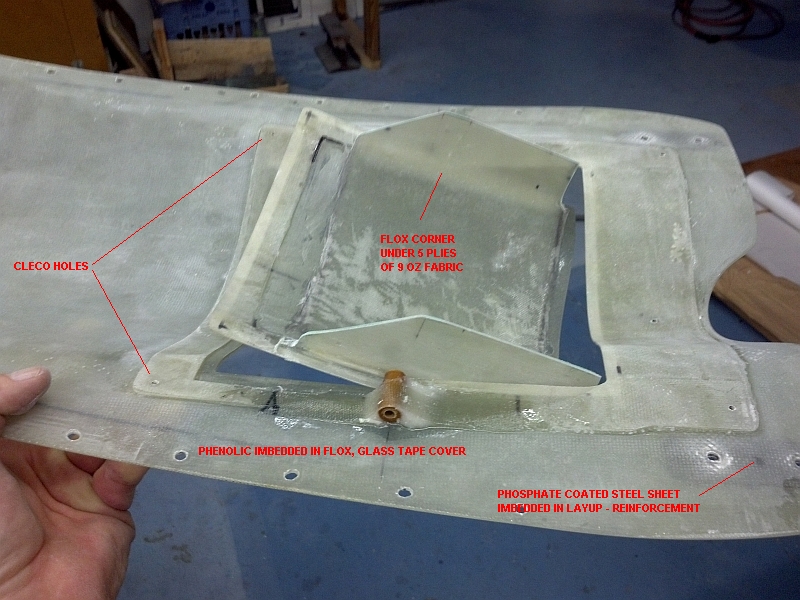

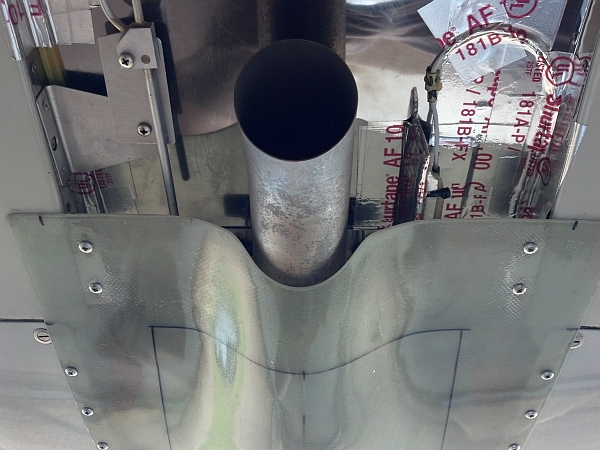

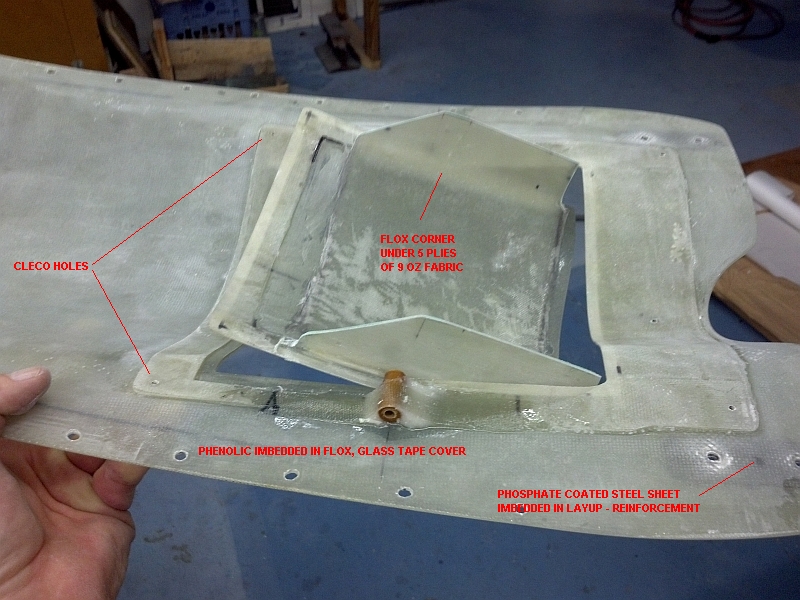

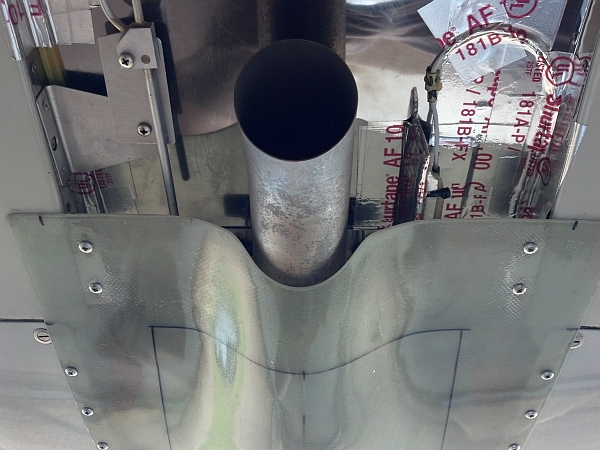

Returning to the cowl outlet panel molded a few posts back. This is variable area cooling exit door. I'll detail the cooling results in other threads after test flight, so please, save those questions. This is about details of fiberglass fabrication.

The door needs a flange for sealing, actually two opposing flanges. Before cutting the door from the panel, the inside of the panel was sprayed with PVA and a four ply layup was done to net a glass section suitable for flange fabrication, as well as general reinforcement around the soon-to-be-cut hole. The section was popped loose, trimmed to overall size, and set aside.

The door was cut in the panel with a fine blade jigsaw. After the edges were sanded clean and straight the hinge line was determined and the previously made glass section was cut so as to form a flange on the big panel and another flange on the forward half of door itself. The cut flange/reinforcement parts were then bonded into the cowl panel and onto the door. Clecos are the easy way to locate and apply moderate bond pressure. The holes are easily filled during the finishing steps later.

The hinge points are phenolic rod drilled for -3 bolts. Phenolic bonds into glass assemblies very well. It's not suitable for hinges if there is a lot of movement, but will do fine here. The phenolic is imbedded in flox, then a few plies of glass is applied over the flox while wet. In the photo below, the phenolic hinges are not yet installed in the door itself.

The vertical ribs on the door started as a two-ply layup flat on the bench, merely to form a flat piece of glass which could be trimmed to shape, much as you might trim a piece of aluminum. Peel ply on both sides made the subsequent surface bond-ready without much fooling around. The ribs were cut from the cured glass, then jigged in place with a few tiny dabs of five-minute epoxy. When cured so they would stand in place, a generous flox fillet was wiped into the inboard corners, then a 6-ply layup was placed across the inside of the door and up the inboard side of the ribs.

Internal cowl pressure will apply a significant load to the full-time exit slot at the aft end of the panel, which now extends 4" aft of the firewall plane. To help with the point loads at the attach screws, 1' x 3" tabs of phosphate coated steel sheet were imbedded at the rearmost attach points. As it happens, steel and epoxy/glass are close on the coefficient of thermal expansion scale.

After everything is bonded in place, the usual filling and finishing methods make it slick.

BTW, none of this is West epoxy. There is a lot of radiant heat near the exhaust header, and exit air temperature can exceed 200F. The epoxy used here is HTR-212, chosen for its high heat distortion temperature. The door could not be expected to last if it turned into a limp noodle when hot.

http://www.aircraftspruce.com/catalog/cmpages/htr212resin.php

The inside will get a fiberfrax layer in a selected locations, under a layer of reflective aluminum foil.

POSTSCRIPT Late December:

Test flight showed that the above didn't provide enough support for the hinge points; internal pressure bowed the panel outward and the door could not fully close.

The cure was the addition of a rib along each side of the door opening to support the hinge points. Wood is an excellent core material. These ribs are 1/4 thick red oak, but almost any straight grain non-oily hardwood would be fine here. For serious design efforts refer to ANC-18 and ANC-19.

The ribs were floxed into place. After cure the flox was sanded to a neat concave fillet and two plies of 8.9 oz 8 harness were added. After finish sanding a coat of neat epoxy sealed the surface, and later the ribs were covered in reflective self-stick aluminum as a heat shield.

The door needs a flange for sealing, actually two opposing flanges. Before cutting the door from the panel, the inside of the panel was sprayed with PVA and a four ply layup was done to net a glass section suitable for flange fabrication, as well as general reinforcement around the soon-to-be-cut hole. The section was popped loose, trimmed to overall size, and set aside.

The door was cut in the panel with a fine blade jigsaw. After the edges were sanded clean and straight the hinge line was determined and the previously made glass section was cut so as to form a flange on the big panel and another flange on the forward half of door itself. The cut flange/reinforcement parts were then bonded into the cowl panel and onto the door. Clecos are the easy way to locate and apply moderate bond pressure. The holes are easily filled during the finishing steps later.

The hinge points are phenolic rod drilled for -3 bolts. Phenolic bonds into glass assemblies very well. It's not suitable for hinges if there is a lot of movement, but will do fine here. The phenolic is imbedded in flox, then a few plies of glass is applied over the flox while wet. In the photo below, the phenolic hinges are not yet installed in the door itself.

The vertical ribs on the door started as a two-ply layup flat on the bench, merely to form a flat piece of glass which could be trimmed to shape, much as you might trim a piece of aluminum. Peel ply on both sides made the subsequent surface bond-ready without much fooling around. The ribs were cut from the cured glass, then jigged in place with a few tiny dabs of five-minute epoxy. When cured so they would stand in place, a generous flox fillet was wiped into the inboard corners, then a 6-ply layup was placed across the inside of the door and up the inboard side of the ribs.

Internal cowl pressure will apply a significant load to the full-time exit slot at the aft end of the panel, which now extends 4" aft of the firewall plane. To help with the point loads at the attach screws, 1' x 3" tabs of phosphate coated steel sheet were imbedded at the rearmost attach points. As it happens, steel and epoxy/glass are close on the coefficient of thermal expansion scale.

After everything is bonded in place, the usual filling and finishing methods make it slick.

BTW, none of this is West epoxy. There is a lot of radiant heat near the exhaust header, and exit air temperature can exceed 200F. The epoxy used here is HTR-212, chosen for its high heat distortion temperature. The door could not be expected to last if it turned into a limp noodle when hot.

http://www.aircraftspruce.com/catalog/cmpages/htr212resin.php

The inside will get a fiberfrax layer in a selected locations, under a layer of reflective aluminum foil.

POSTSCRIPT Late December:

Test flight showed that the above didn't provide enough support for the hinge points; internal pressure bowed the panel outward and the door could not fully close.

The cure was the addition of a rib along each side of the door opening to support the hinge points. Wood is an excellent core material. These ribs are 1/4 thick red oak, but almost any straight grain non-oily hardwood would be fine here. For serious design efforts refer to ANC-18 and ANC-19.

The ribs were floxed into place. After cure the flox was sanded to a neat concave fillet and two plies of 8.9 oz 8 harness were added. After finish sanding a coat of neat epoxy sealed the surface, and later the ribs were covered in reflective self-stick aluminum as a heat shield.

Last edited:

mculver

Well Known Member

This is an epic thread; however some of the embedded photos at the top of the thread seem to have been removed from the server that hosted them. Any chance of re[posting/fixing the thread with fresh links?

I will volunteer to host the photos or a rewrite/consolidation as an article) if that helps.

I will volunteer to host the photos or a rewrite/consolidation as an article) if that helps.

flyingriki

Well Known Member

KatieB

Well Known Member

First step is to develop a shape. You can use whatever works. Clay is popular. I used pour-in-place foam this time, and a few cut back chunks of an old Van's fairing. Tape off the aluminum to protect it and shape your medium as required.

Hey Dan or anyone else who's used pourable foam-- I have some Fibre Glast pourable foam, and before pouring it into my empennage fairing cavity, I did a test with some plastic containers. This stuff really sticks to the plastic! How did you get it cleaned off the tail cavity after you laid up the fairing? Did you have to spray some mold release in there? Right now I just have packing tape protecting the metal and filling the holes.

KatieB

Well Known Member

So I answered my own question... I sat there a few minutes staring at it, then grabbed some 1" bead foam and made some divider inserts for the cavity under the VS. This way, the foam won't be a solid chunk wedged in there and I should be able to cut/lift it out of there easier. After working with the foam on the airplane, I realized that it does release very easily from the packing tape.

[/url]2016-09-10_05-05-00 by jabiruchick, on Flickr[/IMG]

[/url]2016-09-10_05-05-00 by jabiruchick, on Flickr[/IMG]

I've found that the pourable foam looks a lot like Great Stuff foam in a can, but its air pockets are much smaller and it carves much easier. I can almost feather it down to a wedge. It only took a couple of hours to whittle it down to a workable plug.

[/url]2016-09-10_05-06-12 by jabiruchick, on Flickr[/IMG]

[/url]2016-09-10_05-06-12 by jabiruchick, on Flickr[/IMG]

[/url]2016-09-10_05-20-12 by jabiruchick, on Flickr[/IMG]

[/url]2016-09-10_05-20-12 by jabiruchick, on Flickr[/IMG]

I've found that the pourable foam looks a lot like Great Stuff foam in a can, but its air pockets are much smaller and it carves much easier. I can almost feather it down to a wedge. It only took a couple of hours to whittle it down to a workable plug.

Bob Martin

Well Known Member

Nice Work Katie.

I did the same thing on my -6.

and wrapped the front edge around the leading edge of the HS.

This way I only needed 2 screws in the rear each side to hold it on.

Very clean looking. Your foam work is much cleaner than mine was, it was a real mess!

I did the same thing on my -6.

and wrapped the front edge around the leading edge of the HS.

This way I only needed 2 screws in the rear each side to hold it on.

Very clean looking. Your foam work is much cleaner than mine was, it was a real mess!

You're doing fine Katie, as usual.

A note about the two-part pour foam; although it works great as a form material, don't try to use it as core inside a finished component. It seems to break down over time given enough pressure changes.

I tried pour foam inside the wingtip shells, near the trailing edges, to stiffen them just as we might use it to stiffen an enclosed space in a kayak. Over time, the foam expanded in places and compressed in others, creating lumpy highs and lows in the surface. It has since been removed.

I also allowed a very small amount of pour foam to remain as core above the inlets in the modified cowl, and within a year, a surface depression began to form over the foam. A bit of reasoning said it had to be fueled by pressure changes, so I drilled a tiny vent hole into the foam cavity from the inside of the cowl. In a few months the fiberglass surface plies regained their original contour.

A note about the two-part pour foam; although it works great as a form material, don't try to use it as core inside a finished component. It seems to break down over time given enough pressure changes.

I tried pour foam inside the wingtip shells, near the trailing edges, to stiffen them just as we might use it to stiffen an enclosed space in a kayak. Over time, the foam expanded in places and compressed in others, creating lumpy highs and lows in the surface. It has since been removed.

I also allowed a very small amount of pour foam to remain as core above the inlets in the modified cowl, and within a year, a surface depression began to form over the foam. A bit of reasoning said it had to be fueled by pressure changes, so I drilled a tiny vent hole into the foam cavity from the inside of the cowl. In a few months the fiberglass surface plies regained their original contour.

Northernliving

Well Known Member

Thanks for posting this Dan. I'm just starting my -8, and trying to learn all that I can. this is very helpful.

Also, for those interested, There are several *very* good Mike Arnold glassing videos on YouTube. Mike was the builder of the AR-5 and was very knowledgeable aerodynamics, composites and glass. Mike has passed away, but his family has been positing his videos.

Here is one on building moldless low drag wheel pants.

https://www.youtube.com/watch?v=kjOt76LcKjU

-Brian

Also, for those interested, There are several *very* good Mike Arnold glassing videos on YouTube. Mike was the builder of the AR-5 and was very knowledgeable aerodynamics, composites and glass. Mike has passed away, but his family has been positing his videos.

Here is one on building moldless low drag wheel pants.

https://www.youtube.com/watch?v=kjOt76LcKjU

-Brian

lots to learn

Great stuff.

Brian, thanks for sharing this. It was really helpful. One important thing I just learned from his video - it's normal for it to take a lot of long time to do this work - he said he spent 30 hours just on forming the shape for the wheel pants - and he's obviously pretty experienced. Also, making parts that fit and look perfect can be done, but require an investment in time and prep. I was also surprised to see his generous application of micro - I have been very stingy with it. I didn't realize it was strong enough to be the outside layer of a part like that which is under so much abuse....

Also, for those interested, There are several *very* good Mike Arnold glassing videos on YouTube. ...

Here is one on building moldless low drag wheel pants.

https://www.youtube.com/watch?v=kjOt76LcKjU

Great stuff.

Northernliving

Well Known Member

Mickey, yes. Mike Arnold spends an considerable amount of time, but the results are stunning. I've watched all his videos while on the treadmill... and yeah, makes the time go by fast! I'll probably download them for reference just in case they don't last on youtube.Brian, thanks for sharing this. It was really helpful. One important thing I just learned from his video - it's normal for it to take a lot of long time to do this work - he said he spent 30 hours just on forming the shape for the wheel pants - and he's obviously pretty experienced. Also, making parts that fit and look perfect can be done, but require an investment in time and prep. I was also surprised to see his generous application of micro - I have been very stingy with it. I didn't realize it was strong enough to be the outside layer of a part like that which is under so much abuse.

Great stuff.

Brian

az_gila

Well Known Member

It's like that E6Ti...it's generally found in old used cars.

Not quite, it is one of the standard re-finish technique for the epoxy structures of sailplanes. Lots of proof over decades that it adheres, stays white and lasts much longer than the standard German factory finishes.

The Prestec primer followed by a Prestec white polyester paint that is sanded and polished before (24-48 hrs) it gets really hard.

They basically make industrial coating but specifically cater to the sailplane industry - http://simteccoatings.com/index2.ivnu When I visited the plant (a small industrial building in an industrial strip mall) the owner was amused that the sailplane guys took his "oil rig paint" and polished it.

The rumor was that Burt Rutan had a hangar next to Fred Jiran in Mojave airport in 1969. Fred was one of the first shops specializing in repair of the then newly imported German fiberglass sailplanes and Burt was admiring how smooth the wings were - which led to the VariEze.

Update - not a rumor -

http://codevco.ws/Composite_pages/Aircraft/VariEze/varieze_home.htm

Last edited:

Not quite, it is one of the standard re-finish technique for the epoxy structures of sailplanes.

Ok, it's used on old used cars and old used gliders.

MonkeyWrench

Member

Wow. About to do my first fiberglass work on my RV14. This is such a great thread. Read most of it and learned a lot. Does anyone know what part number on ACS to use for peel-ply? I searched ACS for peel-ply and the only thing that comes up is POROUS TEFLON? COATED RELEASE FILM. https://www.aircraftspruce.com/catalog/cmpages/vb7025.php

Also, still reading these, but someone called out the kit planes articles on Composites in this thread. They are all online now. For anyone looking for them, i listed them below. They are spread out over 11 different monthly issues.

Kit planes Articles Build your skills: Composites by Bob Fritz (Need login to kit planes)

Build Your Skills: Composites (Part 1)

http://www.kitplanes.com/issues/24_5/builder_spotlight/7864-1.html

Build Your Skills: Composites (Part 2)

http://www.kitplanes.com/issues/24_6/builder_spotlight/7887-1.html

Build Your Skills: Composites (Part 3) - Kitplanes

www.kitplanes.com/issues/24_7/builder_spotlight/7922-1.html

In Part 3, we look at how to go about basic preparations; by Bob Fritz.

Build Your Skills: Composites (Part 4) - Kitplanes

www.kitplanes.com/issues/24_8/builder_spotlight/7956-1.html

In Part 4, we make parts from molds; by Bob Fritz. ... Build Your Skills: Composites (Part 4). By Bob Fritz. In Part 4, we make parts from molds; by Bob Fritz.

Build Your Skill: Composites, Part 5 - Kitplanes

www.kitplanes.com/issues/24_9/builder.../kitplanes_issues_builderspotlight_7978-1.html

Build Your Skill: Composites, Part 5. Part 5: working with carbon fiber. By Bob Fritz. In this series installment, author Bob Fritz takes you through the basics of ...

Build Your Skills: Composites (Part 6) - Kitplanes

www.kitplanes.com/issues/24.../builder.../kitplanes_issues_builderspotlight_8007-1.ht...

Build Your Skills: Composites (Part 6). Part 6: Enough theory! Let's build some wheel chocks. By Bob Fritz. In this series installment, author Bob Fritz takes you ?

Build Your Skills: Composites (Part 7)

Author Bob Fritz explains how to set up a vacuum-bagging operation in your home shop, using readily available equipment and supplies, which will get you great results on small- to medium-size parts. The object is to mechanically ?squeeze? out excess epoxy for a good-ratio part with maximum weight savings and strength.

Build Your Skills: Composites (Part 8) - Kitplanes

www.kitplanes.com/issues/24.../builder.../kitplanes_issues_builderspotlight_8062-1.html

Build Your Skills: Composites (Part 8). Part 8: Building a vacuum pump. By Bob Fritz. Last month's installment in the Composites series detailed how to do ...

Build Your Skills: Composites (Part 9)

Don?t let pesky pinholes ruin your homebuilt project. There is a way to deal with them, and author Bob Fritz describes how. Hint: To start with, cleanliness is always a good thing in the shop.

Build Your Skills: Composites (Part 10) - Kitplanes

www.kitplanes.com/issues/25.../builder.../kitplanes_issues_builderspotlight_8113-1.ht...

Composites, horizontal stabilizer, tail, Bob Fritz, heat gun, level, digital level, epoxy/flox, C clamp, weights, sheet metal screws, tail cone, twist, veterinary syringe, ..

Build Your Skills: Composites (Part 11) - Kitplanes

www.kitplanes.com/issues/25_3/builder.../issues_builderspotlight_8134-1.html

Bob Fritz, spray painting, environmental regulations, composites, Joe Fields, Fields Aviation, Jerry Stimple, sanding, Scotch-Brite, 409 cleanser, Simple ?

Also, still reading these, but someone called out the kit planes articles on Composites in this thread. They are all online now. For anyone looking for them, i listed them below. They are spread out over 11 different monthly issues.

Kit planes Articles Build your skills: Composites by Bob Fritz (Need login to kit planes)

Build Your Skills: Composites (Part 1)

http://www.kitplanes.com/issues/24_5/builder_spotlight/7864-1.html

Build Your Skills: Composites (Part 2)

http://www.kitplanes.com/issues/24_6/builder_spotlight/7887-1.html

Build Your Skills: Composites (Part 3) - Kitplanes

www.kitplanes.com/issues/24_7/builder_spotlight/7922-1.html

In Part 3, we look at how to go about basic preparations; by Bob Fritz.

Build Your Skills: Composites (Part 4) - Kitplanes

www.kitplanes.com/issues/24_8/builder_spotlight/7956-1.html

In Part 4, we make parts from molds; by Bob Fritz. ... Build Your Skills: Composites (Part 4). By Bob Fritz. In Part 4, we make parts from molds; by Bob Fritz.

Build Your Skill: Composites, Part 5 - Kitplanes

www.kitplanes.com/issues/24_9/builder.../kitplanes_issues_builderspotlight_7978-1.html

Build Your Skill: Composites, Part 5. Part 5: working with carbon fiber. By Bob Fritz. In this series installment, author Bob Fritz takes you through the basics of ...

Build Your Skills: Composites (Part 6) - Kitplanes

www.kitplanes.com/issues/24.../builder.../kitplanes_issues_builderspotlight_8007-1.ht...

Build Your Skills: Composites (Part 6). Part 6: Enough theory! Let's build some wheel chocks. By Bob Fritz. In this series installment, author Bob Fritz takes you ?

Build Your Skills: Composites (Part 7)

Author Bob Fritz explains how to set up a vacuum-bagging operation in your home shop, using readily available equipment and supplies, which will get you great results on small- to medium-size parts. The object is to mechanically ?squeeze? out excess epoxy for a good-ratio part with maximum weight savings and strength.

Build Your Skills: Composites (Part 8) - Kitplanes

www.kitplanes.com/issues/24.../builder.../kitplanes_issues_builderspotlight_8062-1.html

Build Your Skills: Composites (Part 8). Part 8: Building a vacuum pump. By Bob Fritz. Last month's installment in the Composites series detailed how to do ...

Build Your Skills: Composites (Part 9)

Don?t let pesky pinholes ruin your homebuilt project. There is a way to deal with them, and author Bob Fritz describes how. Hint: To start with, cleanliness is always a good thing in the shop.

Build Your Skills: Composites (Part 10) - Kitplanes

www.kitplanes.com/issues/25.../builder.../kitplanes_issues_builderspotlight_8113-1.ht...

Composites, horizontal stabilizer, tail, Bob Fritz, heat gun, level, digital level, epoxy/flox, C clamp, weights, sheet metal screws, tail cone, twist, veterinary syringe, ..

Build Your Skills: Composites (Part 11) - Kitplanes

www.kitplanes.com/issues/25_3/builder.../issues_builderspotlight_8134-1.html

Bob Fritz, spray painting, environmental regulations, composites, Joe Fields, Fields Aviation, Jerry Stimple, sanding, Scotch-Brite, 409 cleanser, Simple ?

Scott Hersha

Well Known Member

Peel ply is Dacron. I went to a local fabric store and bought some, pretty cheap, and it works well. You?ll need some good scissors to cut it. My pizza cutter works well on fiberglass, but not so on Dacron.

Does anyone know what part number on ACS to use for peel-ply? I searched ACS for peel-ply and the only thing that comes up is POROUS TEFLON™ COATED RELEASE FILM. https://www.aircraftspruce.com/catalog/cmpages/vb7025.php

Nope, wrong stuff. That's a vacuum bagging film. Another story for another time.

Cheapskate approach is ordinary dacron polyester aircraft fabric from the guy down the hangar row who covered a tube and rag airplane. There tends to be a lot of scrap and ends of rolls piled up on hangar shelves.

If you buy it, just get 2.7oz uncertified fabric:

https://www.aircraftspruce.com/catalog/cmpages/peelply2.php?clickkey=4113

Wicks seems to have nylon peel ply for less money than Spruce:

http://aircraftproducts.wicksaircraft.com/item/all-categories/nylon-fabric-100-b/100-b

Shop the composite supply houses if you're actually going to spend much money on it. At the professional level, peel ply can get exotic.

Last edited:

David Paule

Well Known Member

The polyester peel ply does not particularly like compound curves. In those places, I use it in strips, slightly overlapping. That works well enough.

I make sure that there's an edge or corner or something of the peel ply that's not got resin on it, so that I have a place to start peeling it from.

Dave

I make sure that there's an edge or corner or something of the peel ply that's not got resin on it, so that I have a place to start peeling it from.

Dave