Like a lot of other people, I didn't bother taking the weight off the wheels in the fitting once I realized that the weight issue doesn't impact the alignment of the trailing edge of the fairing, which is all I really care about.

The movement of the leg fairing would impact the up/down position of the fairing within the intersection fairings (which is why the fairings are not permanently attached to the intersection fairings in either location), but it would not impact the alignment of the trailing edge.

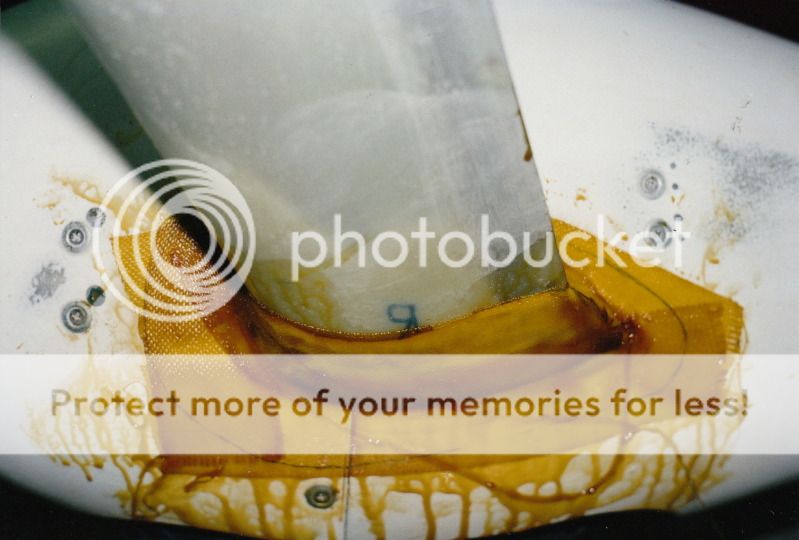

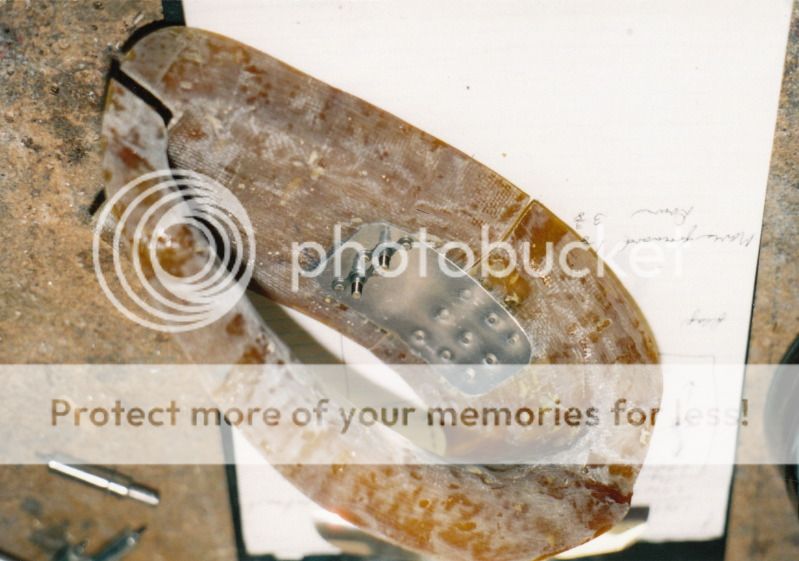

That alignment is "captured" by the position of the fairings around the gear leg.

I obsessed -- capital "O" -- over the alignment of the trailing edge. I used lasers and dental floss. I set and checked it dozens of times before finally committing on Saturday with the installation of the intersection fairings (haven't bonded them yet, though).

It seems to me that there's still opportunity for slop in the trailing edge and that the fairings -- at least at this stage -- cannot perfectly capture the trailing edge.

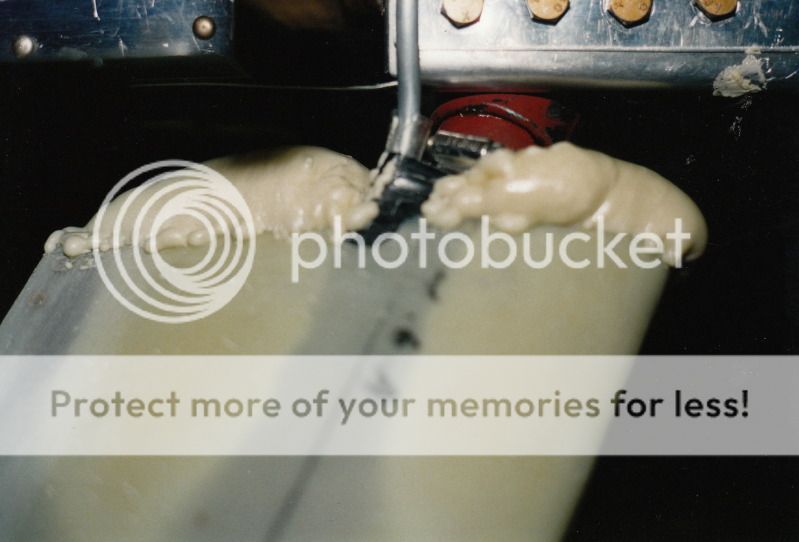

But, I installed them as best I could, took it for a quick test flight around the pattern and all seemed good.

So we stuck my mother in law in...

and went for a ride down to Red Wing and back...

Yahtzee!! The ball was dead centered. It was perfect.

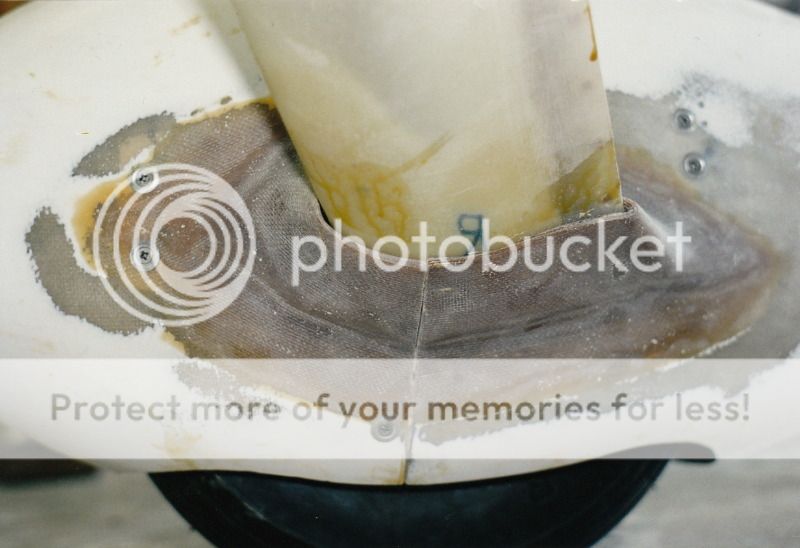

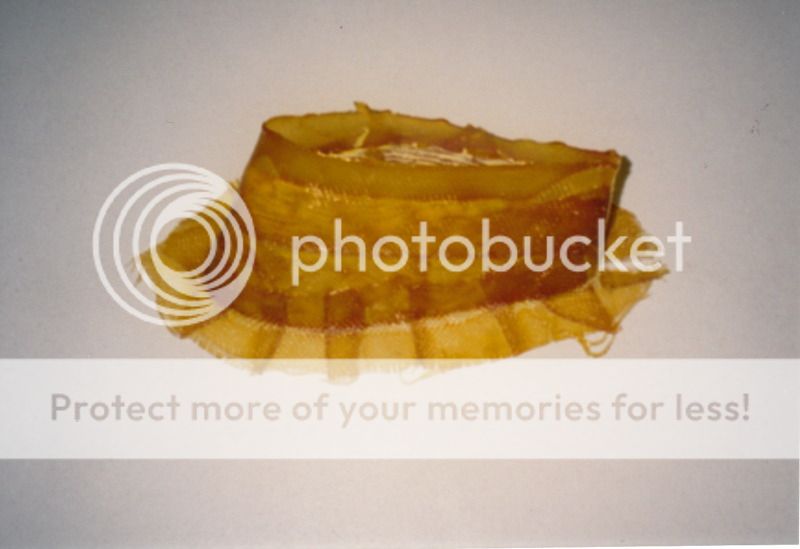

I still have to do the nosewheel leg fairing (I need to cut away more of the slot in the wheelpant to allow the front of the gear leg fairing to fit without interference, and then I'll do the clay-mold things for the intersection fairing.

Oh, and I used a small piece of duct tape to close up the trailing edge of all the intersection fairings. As I get everything glassed up, those, of course, will disappear with bonding. And then I'll slice it as Bob Leffler described above.

I like when things come out the way they're supposed to.