Getting better focused

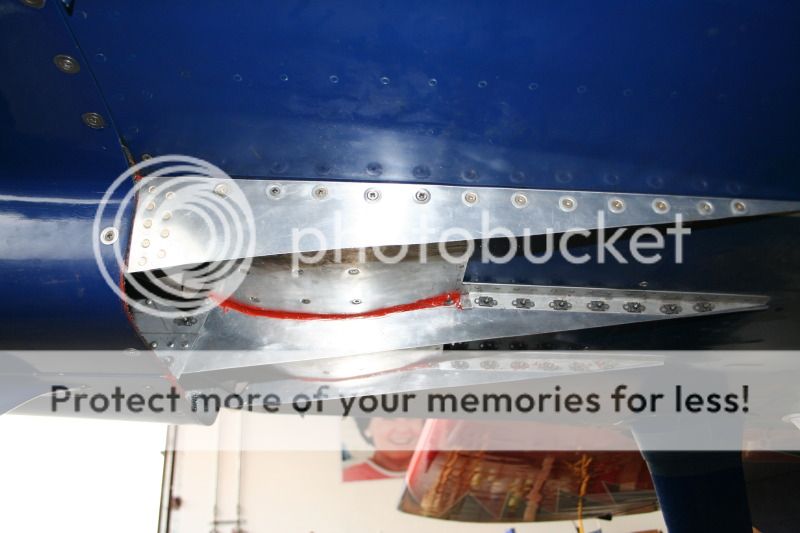

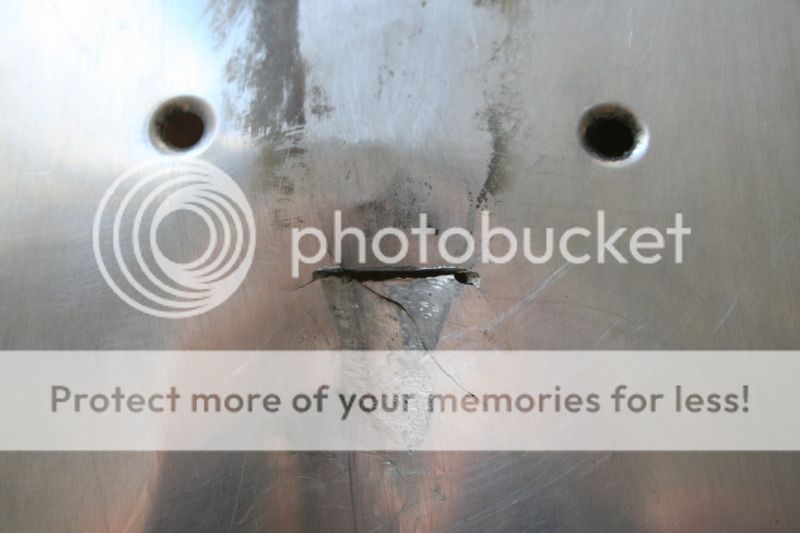

Today went well. The hardest part of some of these mods is the implementation details while preserving the quality of the airplane. It is so frustrating to do rough work to test a concept with things that are crude and it is a double edged sword ... Ah well. I've been fighting some infection with 300 Mg Clindamycin for the last week and today is the first one that I feel like I am good. Consequently I am better organized and patient with this one and it is going to look good and be a good installation even if it doesn't work and that makes me feel good.

Bob Axsom

Today went well. The hardest part of some of these mods is the implementation details while preserving the quality of the airplane. It is so frustrating to do rough work to test a concept with things that are crude and it is a double edged sword ... Ah well. I've been fighting some infection with 300 Mg Clindamycin for the last week and today is the first one that I feel like I am good. Consequently I am better organized and patient with this one and it is going to look good and be a good installation even if it doesn't work and that makes me feel good.

Bob Axsom