I'm looking for good ideas for a priming rack. I'm setting up my shop, getting ready to start an RV-7, and I'd like to have something ready for spraying primer on parts that won't make a mess or aspyxiate me.

I have a nice, heated garage to work in, and I'm thinking of building some sort of expanded-metal table-top rig with a down draft blower exausting thorugh a hose to the outside.

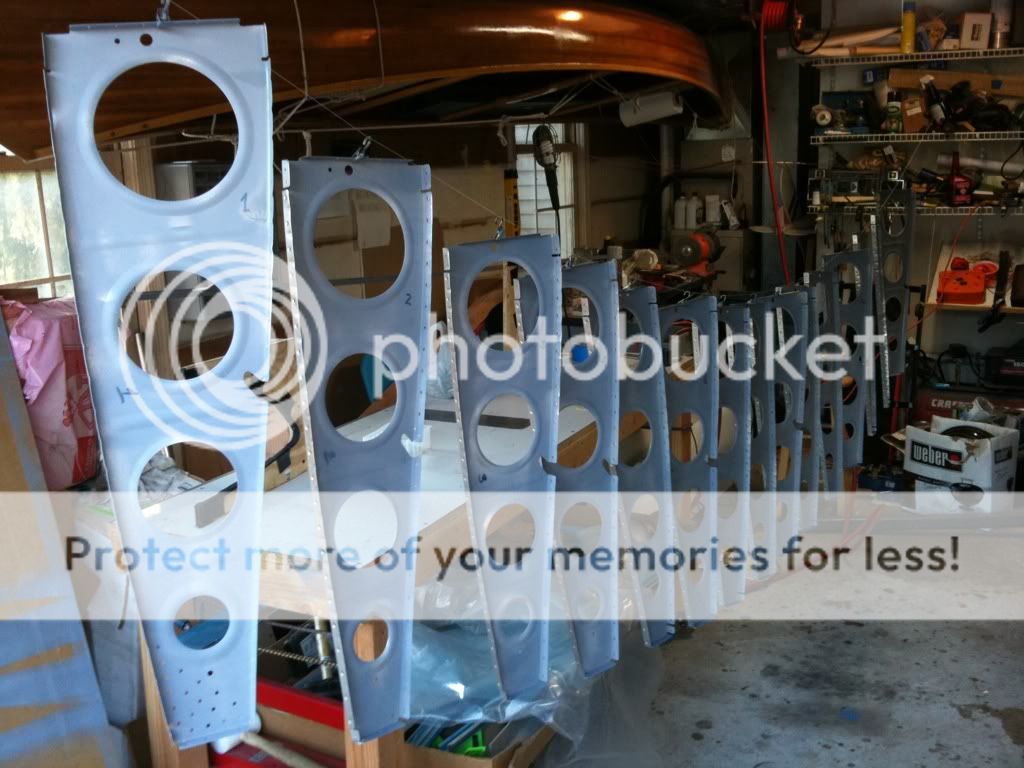

Anyone have some good or bad expereince in this area? Specifically, what size surface do I need (i.e., what's the largest part I will need to spray?) Also, any thoughts on how much airflow will I need & what's the most cost effective source/type of fan?

Thanks

I have a nice, heated garage to work in, and I'm thinking of building some sort of expanded-metal table-top rig with a down draft blower exausting thorugh a hose to the outside.

Anyone have some good or bad expereince in this area? Specifically, what size surface do I need (i.e., what's the largest part I will need to spray?) Also, any thoughts on how much airflow will I need & what's the most cost effective source/type of fan?

Thanks