RV7 QB - Paul and Kacy - Bay Area

Issues with the instructions/drawings:

-Page 7-9 says "QB note, see DWG14A Section B-B". This is in reference to the flap brace install with pop rivets. There is no note in Section B-B and the only rivet referenced in that section is the LP4. The note is in quadrant E-6 of that drawing and specifies structural steel rivets. Don't be like me and have to drill out every single flap brace rivet.

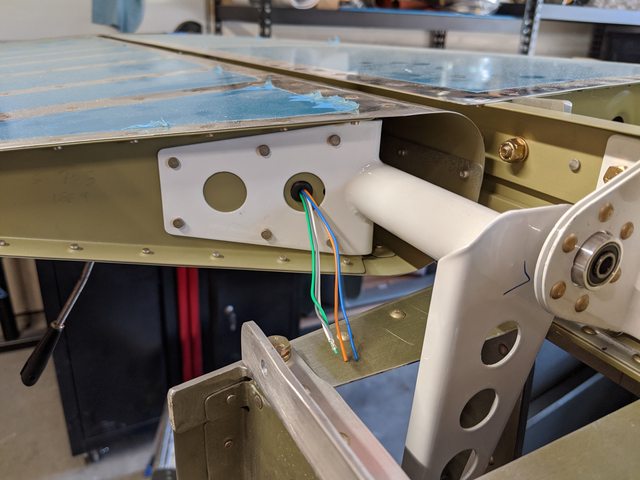

-W716/W818 Aileron pushrod tube length is too short on the drawing. After calling Van's, the numbers on his drawing didn't match the numbers on my drawing, even though we had the same revision and my info packet is less than a month old. The overall length callout seems to be correct, but the call out for how long to cut the tube is about an inch too short. I only had 1 thread engaged.

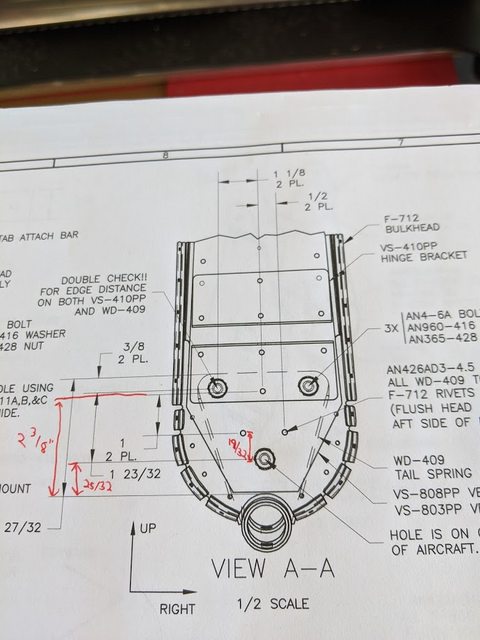

-When installing the tailwheel mount, the "keeper rivets" are referenced to a point that only exists on the vertical stab. I was told to get my vertical out of storage, temporarily install it, and then measure off that in order to drill 2 rivets that really aren't required for a quick build kit. If you're attempting to drill these 2 holes without installing your tail, the measurement you're looking for is 19/32 up from the tooling hole. There's a post with a picture if you want more info.

-Page 8-7 says "Notch longeron around 711-C per DWG 18". It should point you to drawing 27A.

Section 8-9 Brake assembly. The drawing was updated almost 20 years with revision 1 that changes the bolt length call out from an AN3-4 to an AN3-5 for the "skinnier" side of the brake pedal. The "dual brake kit" still provides you with AN3-4 bolts for the passenger side. The quickbuild kit provides AN3-5 bolts for the pilot side. So 20 years after updating the drawing, they haven't updated the BOM for the parts. Also, an AN3-5 bolt will require the maximum 3 washers in order to get the length correct.

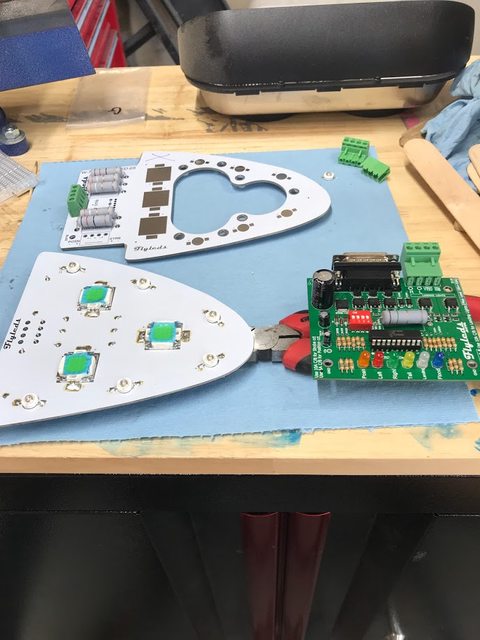

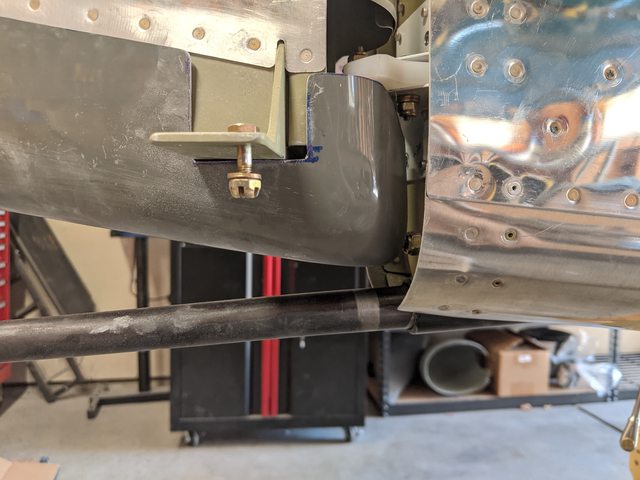

Section 8-9 Making F769-B angle support for the fuel tank mount. Drawing 38 detail F calls out a countersunk screw, washer and nut for the lower mount. Drawing 28 calls out an AN426AD4-6 rivet in that spot. Van's helpline says the screw and nut is the proper hardware.

For quickbuild kits, the half round pieces that hold F786 J stiffeners in place should not be used when drilling to the skin. Remove them, line everything up and then drill. I assumed they were jigs to hold the stiffeners in the correct location and now I have zero edge distance on the front of those stiffeners. To fix it completely would require drilling out the entire stiffener from the already complete aft upper skin and redoing it. Helpline said I would be fine with one or two having 0.020 edge distance, so I'm torn on fixing it correctly, or possibly adding in a doubler because I assumed extra pieces added to the kit would be helpful and not hurtful.

Section 8-11: "Remove the clecoes on the right side of the F-774 (7112) and F-775 skins and lift them up to expose the F-787 stiffener rib. Fabricate the F-707B clip shown on DWG 26. Clamp it to the F-707 bulkhead and F-787 rib. Drill it to the F-707 bulkhead using the pre-punched holes as a guide. When it is clecoed to the bulkhead, drill it to the rib. You may rivet F-707B to F-787, but do not rivet F-707 until the aft top skins are riveted – F-787/F-707B blocks

access to one of the skin rivets." For quick build people, the rivets it tells you not to install come pre-installed. They're a pain to drill out because you can't get a straight shot at them too, so enjoy oversized oval holes when you drill them out in order to be able to rivet the skin on.

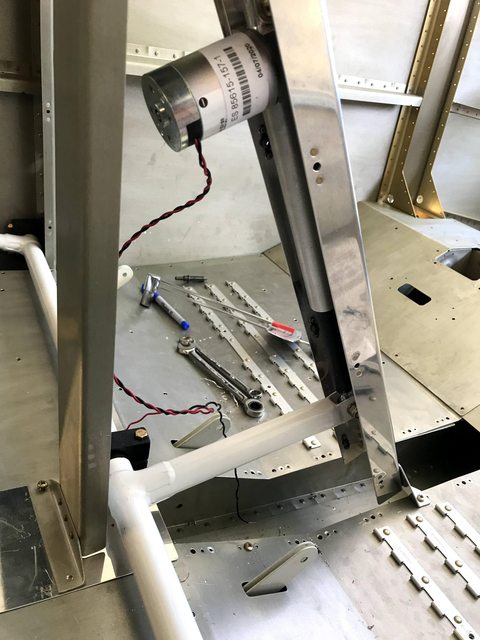

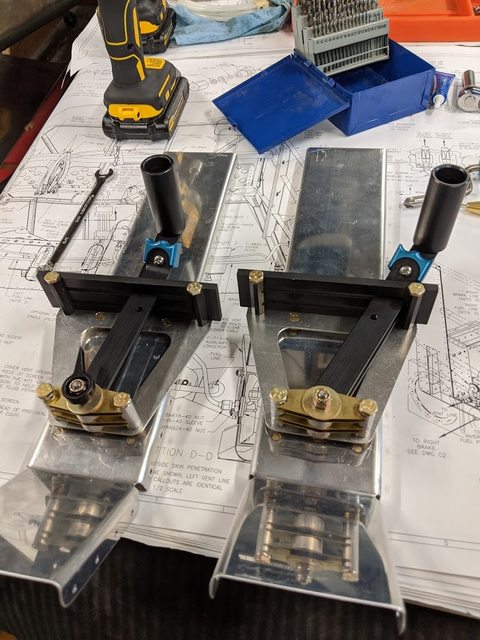

Rudder/Brake pedals: The center pedal support is 0.5" shorter than the side supports. When I drilled my adjustments for the side supports I used the spacing of the bolts as my adjustment, so the front bolt in one location became the rear bolt for the next adjustment. This worked fine until I attempted to drill the center support bracket. Doing this spacing means you'll have holes 1/4" apart from each other in the center because of course that bracket couldn't be the same length. I ordered another side mount bearing block and a new center support bracket. I'll open it up so it isn't closed on one side. This will allow me to have the same center adjustment spacing as the sides I've already drilled.

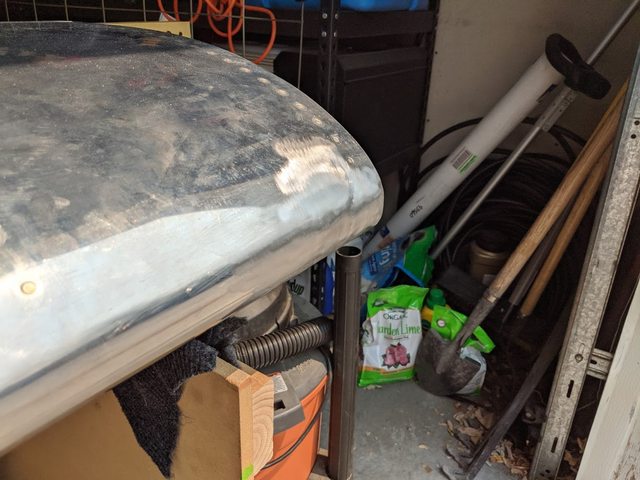

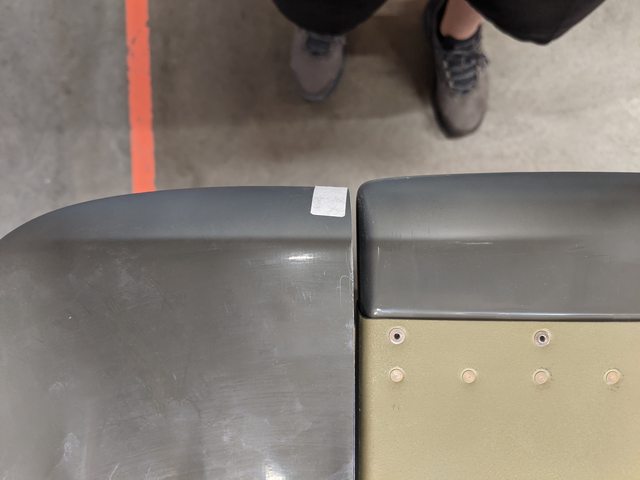

Held off on posting this because doing the tail kit didn't feel like I was actually building yet. Took delivery of the QB fuse, wings and finish kit today, so I guess it's real now. Plan is an aerosport 375 with SDS fuel and ignition, dual g3x panel, smoke, etc. The blog link is in my signature for empannage build details. Today was unboxing and trying to find a spot to put the massive amount of packing paper they include. Tomorrow is inventory. The goal is to fly this to Oshkosh 2022.

Issues with the instructions/drawings:

-Page 7-9 says "QB note, see DWG14A Section B-B". This is in reference to the flap brace install with pop rivets. There is no note in Section B-B and the only rivet referenced in that section is the LP4. The note is in quadrant E-6 of that drawing and specifies structural steel rivets. Don't be like me and have to drill out every single flap brace rivet.

-W716/W818 Aileron pushrod tube length is too short on the drawing. After calling Van's, the numbers on his drawing didn't match the numbers on my drawing, even though we had the same revision and my info packet is less than a month old. The overall length callout seems to be correct, but the call out for how long to cut the tube is about an inch too short. I only had 1 thread engaged.

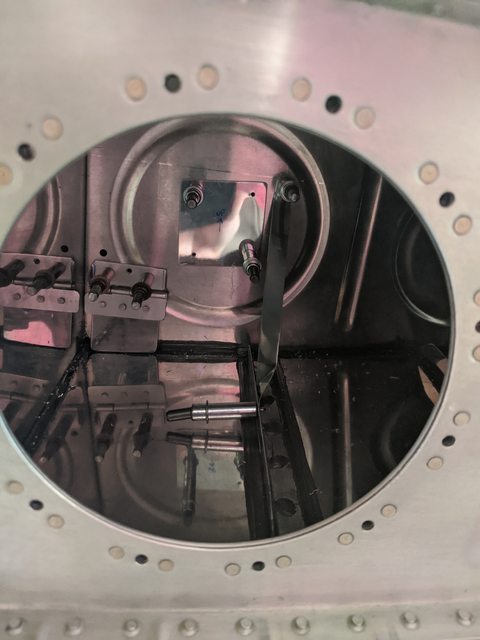

-When installing the tailwheel mount, the "keeper rivets" are referenced to a point that only exists on the vertical stab. I was told to get my vertical out of storage, temporarily install it, and then measure off that in order to drill 2 rivets that really aren't required for a quick build kit. If you're attempting to drill these 2 holes without installing your tail, the measurement you're looking for is 19/32 up from the tooling hole. There's a post with a picture if you want more info.

-Page 8-7 says "Notch longeron around 711-C per DWG 18". It should point you to drawing 27A.

Section 8-9 Brake assembly. The drawing was updated almost 20 years with revision 1 that changes the bolt length call out from an AN3-4 to an AN3-5 for the "skinnier" side of the brake pedal. The "dual brake kit" still provides you with AN3-4 bolts for the passenger side. The quickbuild kit provides AN3-5 bolts for the pilot side. So 20 years after updating the drawing, they haven't updated the BOM for the parts. Also, an AN3-5 bolt will require the maximum 3 washers in order to get the length correct.

Section 8-9 Making F769-B angle support for the fuel tank mount. Drawing 38 detail F calls out a countersunk screw, washer and nut for the lower mount. Drawing 28 calls out an AN426AD4-6 rivet in that spot. Van's helpline says the screw and nut is the proper hardware.

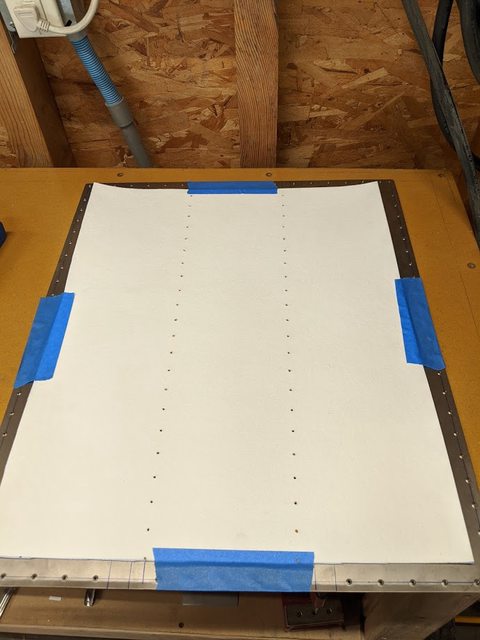

For quickbuild kits, the half round pieces that hold F786 J stiffeners in place should not be used when drilling to the skin. Remove them, line everything up and then drill. I assumed they were jigs to hold the stiffeners in the correct location and now I have zero edge distance on the front of those stiffeners. To fix it completely would require drilling out the entire stiffener from the already complete aft upper skin and redoing it. Helpline said I would be fine with one or two having 0.020 edge distance, so I'm torn on fixing it correctly, or possibly adding in a doubler because I assumed extra pieces added to the kit would be helpful and not hurtful.

Section 8-11: "Remove the clecoes on the right side of the F-774 (7112) and F-775 skins and lift them up to expose the F-787 stiffener rib. Fabricate the F-707B clip shown on DWG 26. Clamp it to the F-707 bulkhead and F-787 rib. Drill it to the F-707 bulkhead using the pre-punched holes as a guide. When it is clecoed to the bulkhead, drill it to the rib. You may rivet F-707B to F-787, but do not rivet F-707 until the aft top skins are riveted – F-787/F-707B blocks

access to one of the skin rivets." For quick build people, the rivets it tells you not to install come pre-installed. They're a pain to drill out because you can't get a straight shot at them too, so enjoy oversized oval holes when you drill them out in order to be able to rivet the skin on.

Rudder/Brake pedals: The center pedal support is 0.5" shorter than the side supports. When I drilled my adjustments for the side supports I used the spacing of the bolts as my adjustment, so the front bolt in one location became the rear bolt for the next adjustment. This worked fine until I attempted to drill the center support bracket. Doing this spacing means you'll have holes 1/4" apart from each other in the center because of course that bracket couldn't be the same length. I ordered another side mount bearing block and a new center support bracket. I'll open it up so it isn't closed on one side. This will allow me to have the same center adjustment spacing as the sides I've already drilled.

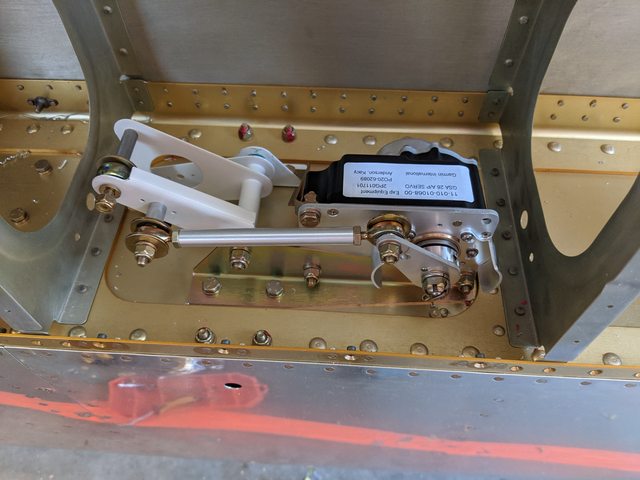

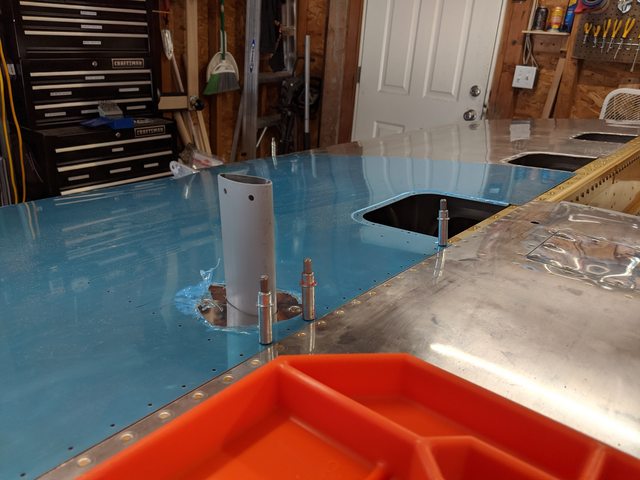

Held off on posting this because doing the tail kit didn't feel like I was actually building yet. Took delivery of the QB fuse, wings and finish kit today, so I guess it's real now. Plan is an aerosport 375 with SDS fuel and ignition, dual g3x panel, smoke, etc. The blog link is in my signature for empannage build details. Today was unboxing and trying to find a spot to put the massive amount of packing paper they include. Tomorrow is inventory. The goal is to fly this to Oshkosh 2022.

Last edited: