Another good day today. I'm beat after today, a lot of up and down movement. However, it was awesome to be installing systems on the engine.

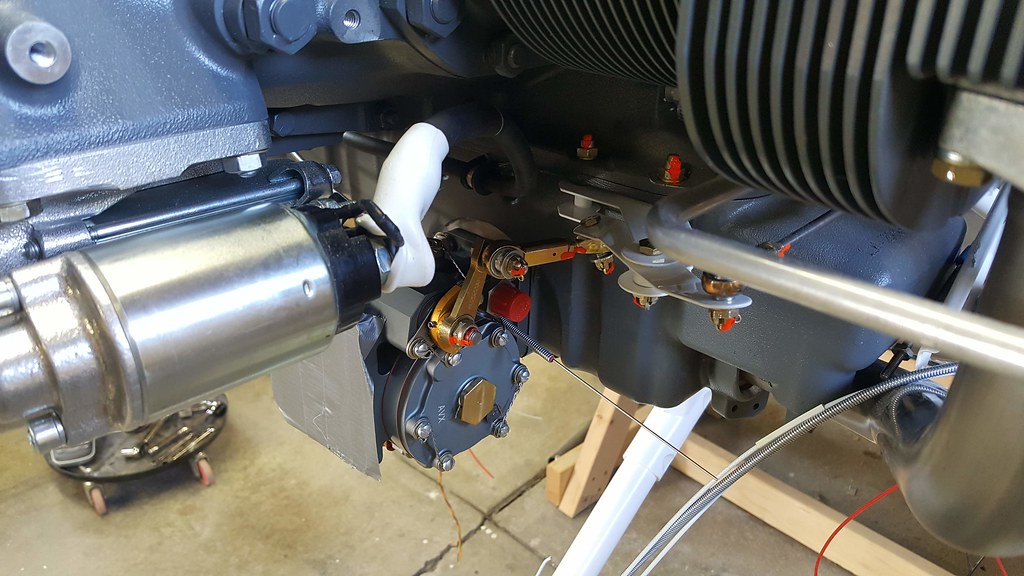

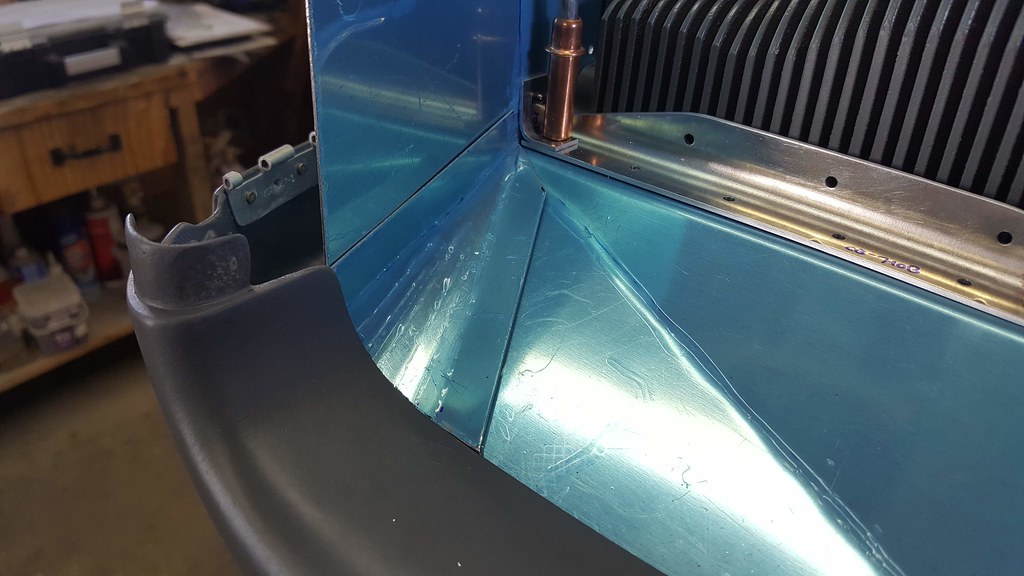

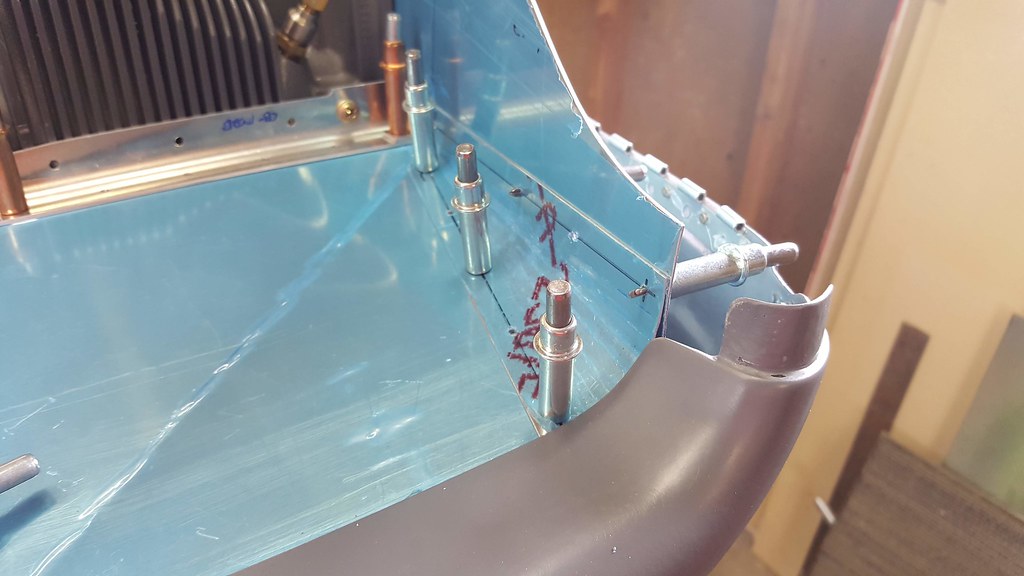

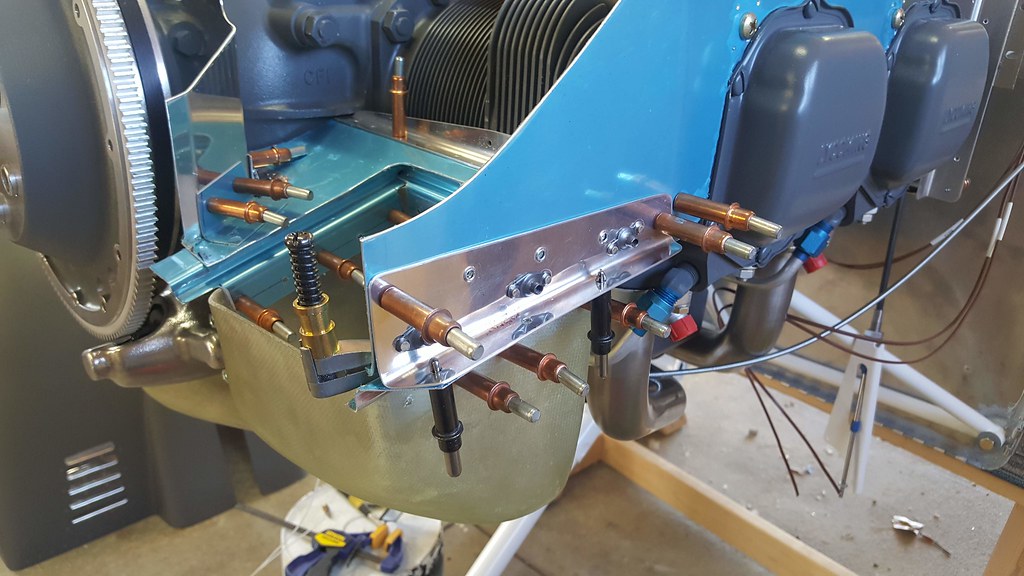

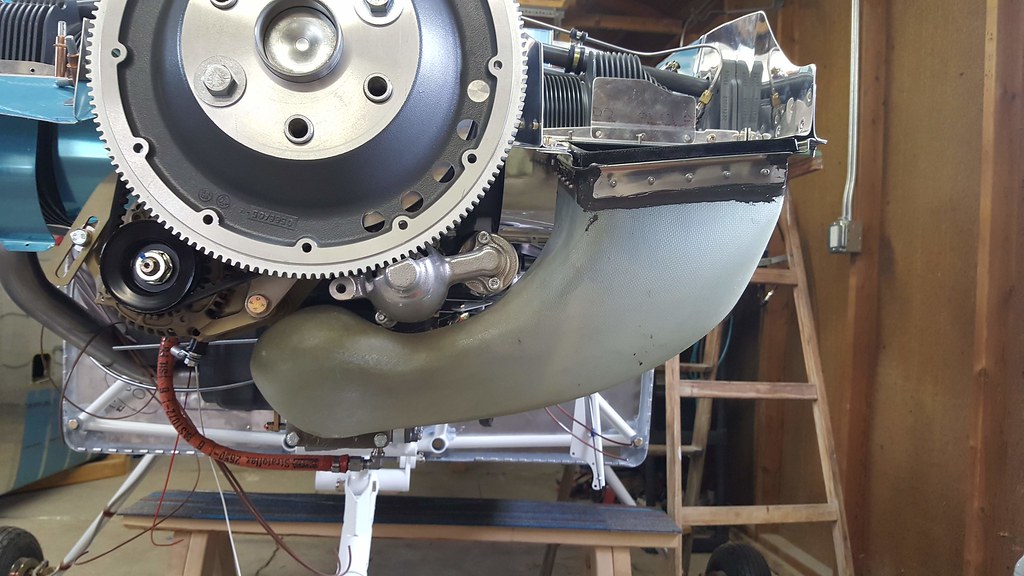

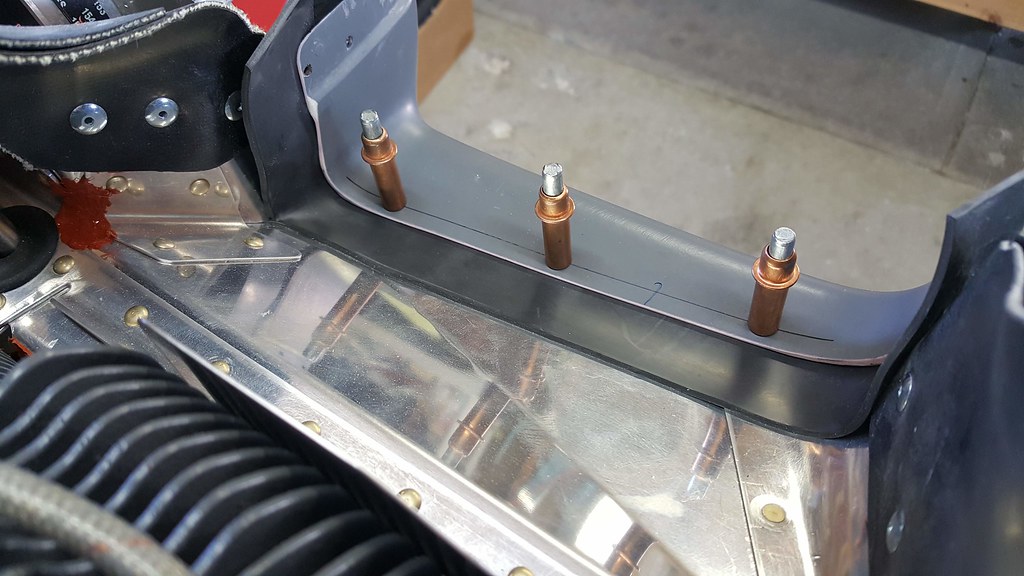

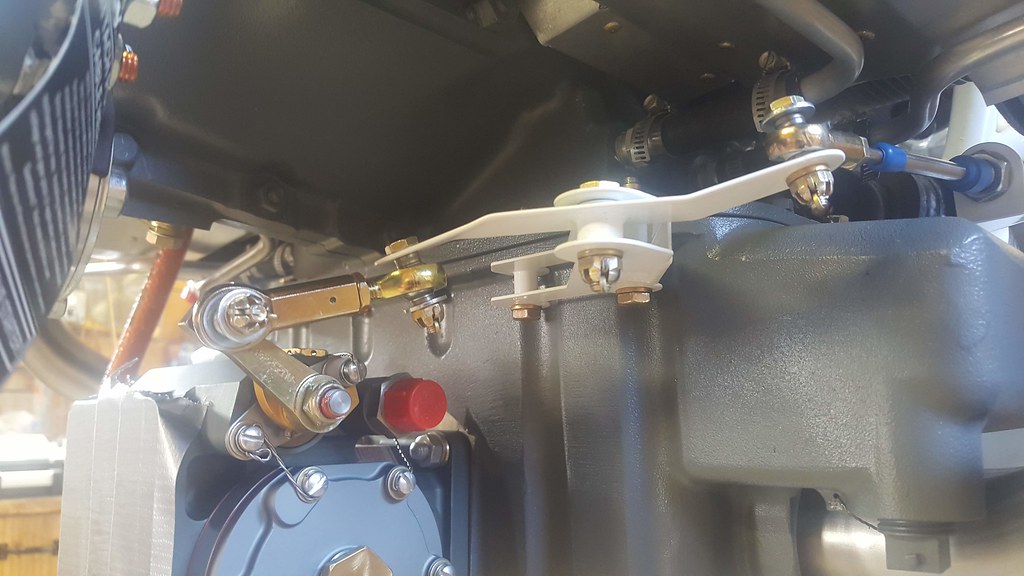

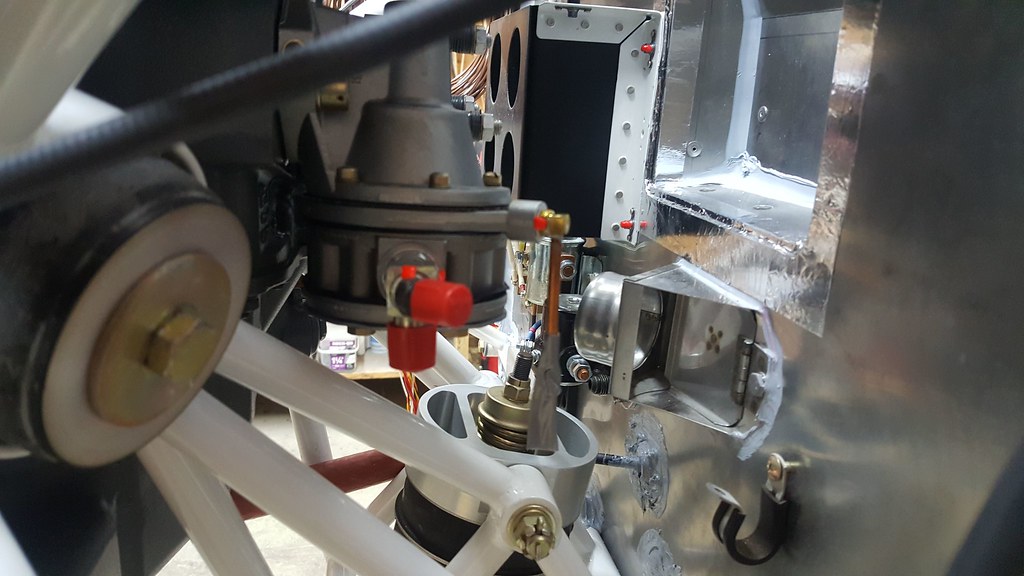

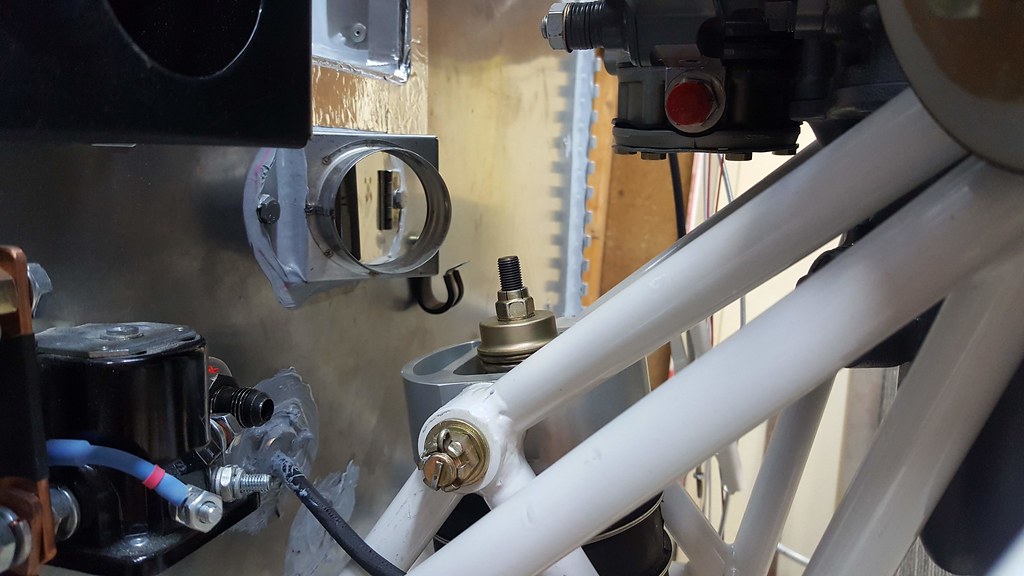

After installing the Avstar fuel servo I focused on the mixture control cable. This little Rube Goldberg contraption I think is just so cool! It works wonderfully too. It took awhile to adjust things to made sure I was hitting the stops. Just a tip for others, set the cable to the full rich stop first and the other one will take care of itself. But make sure to verify!

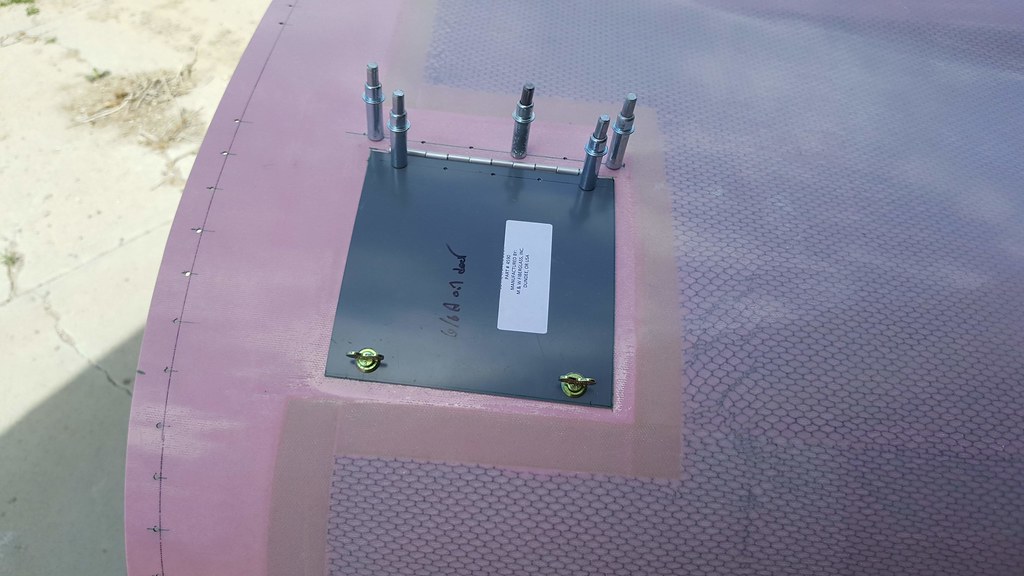

20200530_140159 by Jereme Carne, on Flickr

20200530_140159 by Jereme Carne, on Flickr

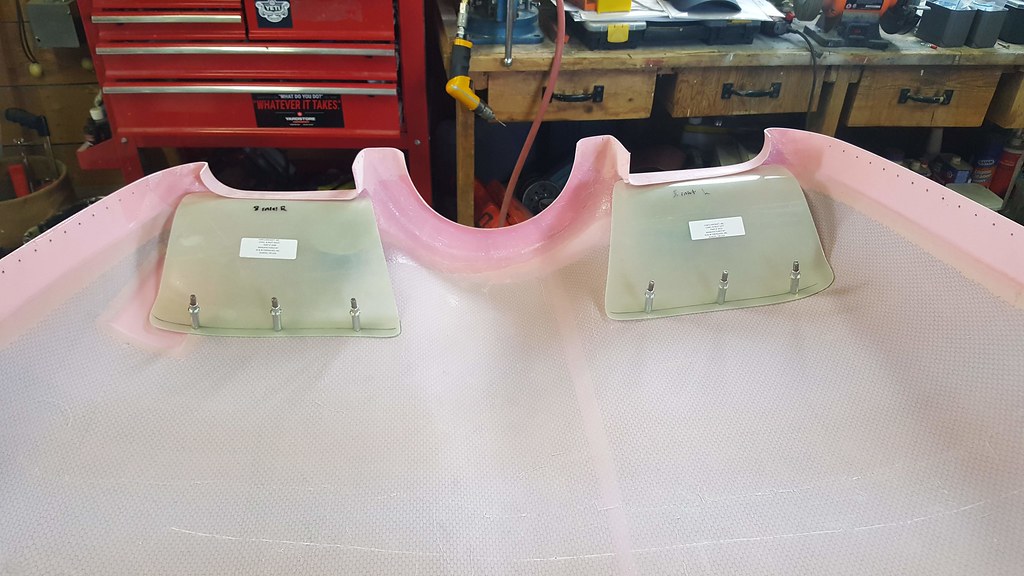

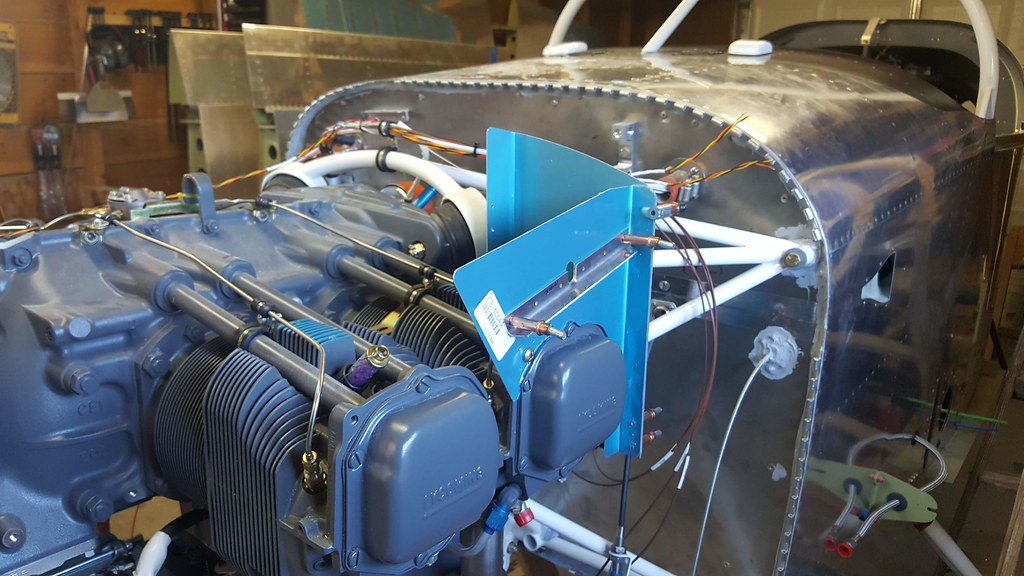

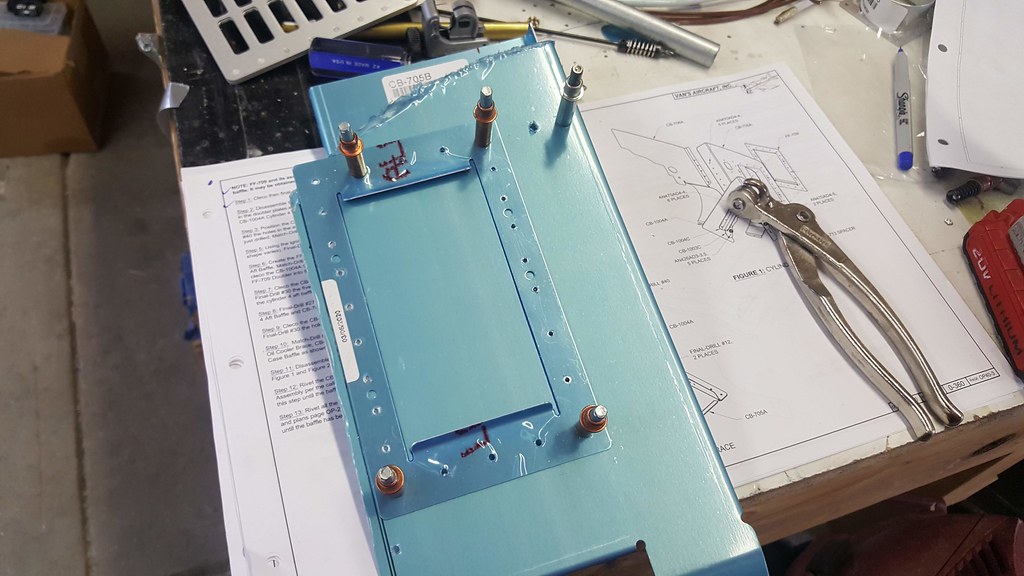

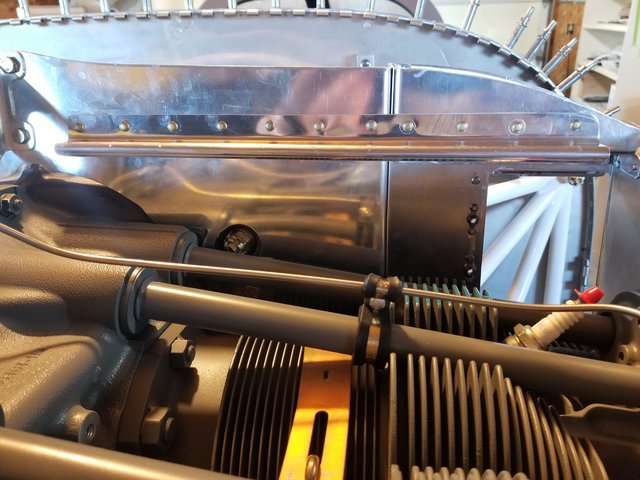

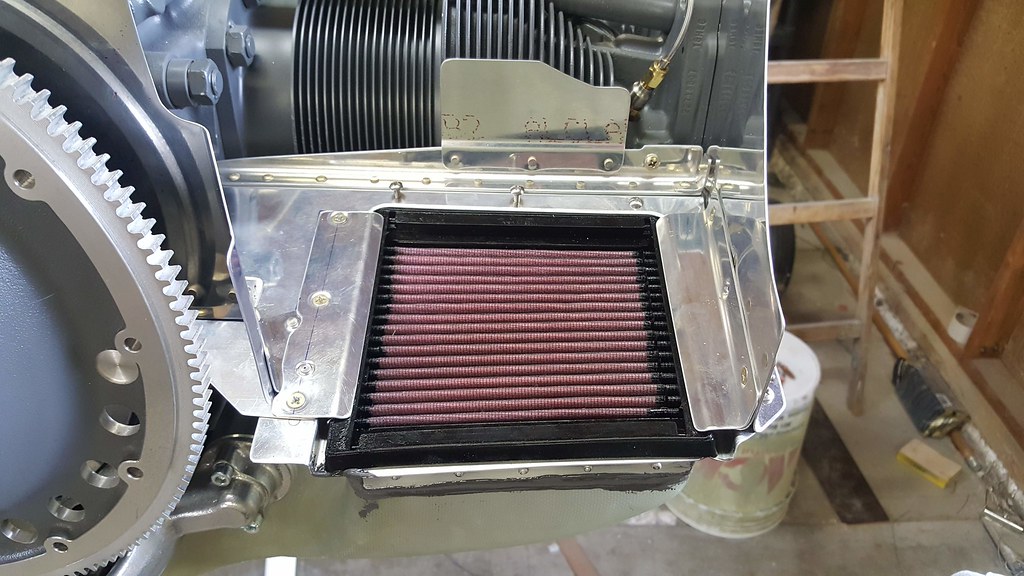

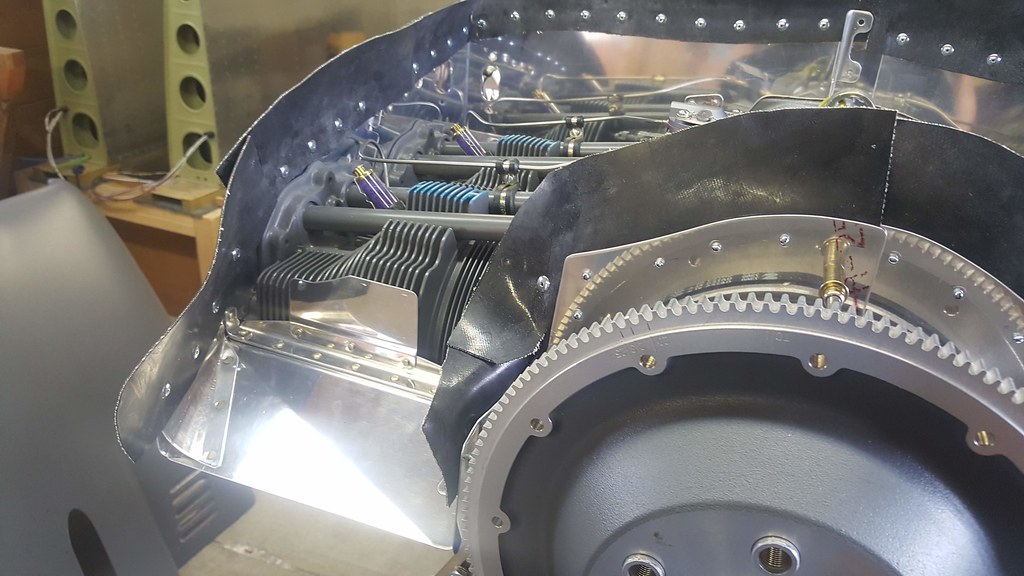

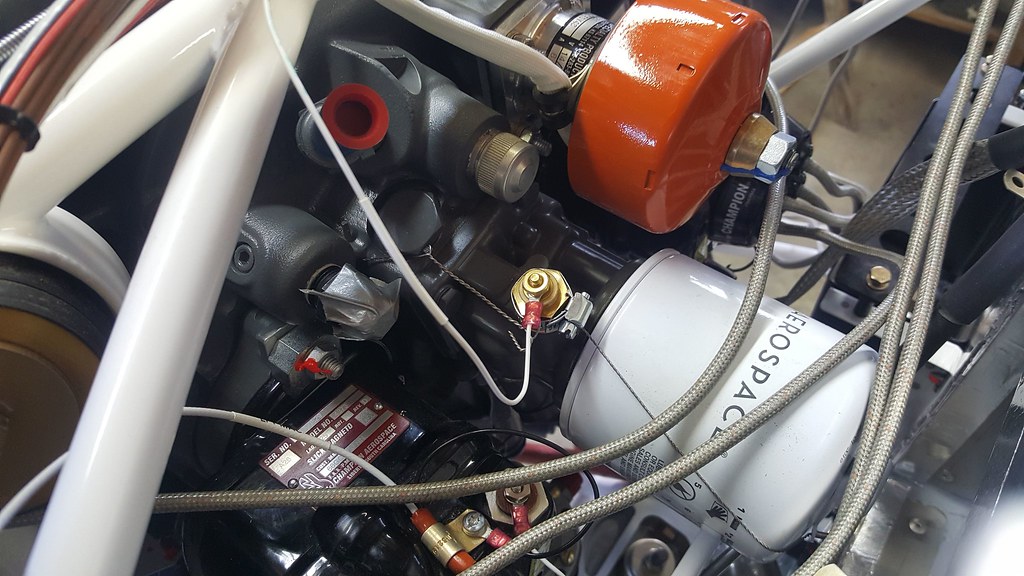

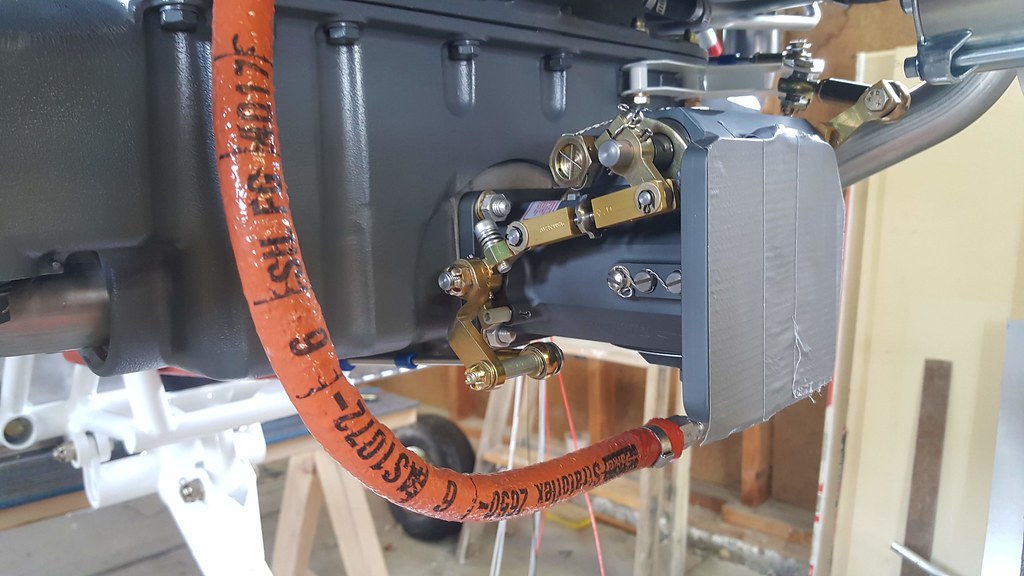

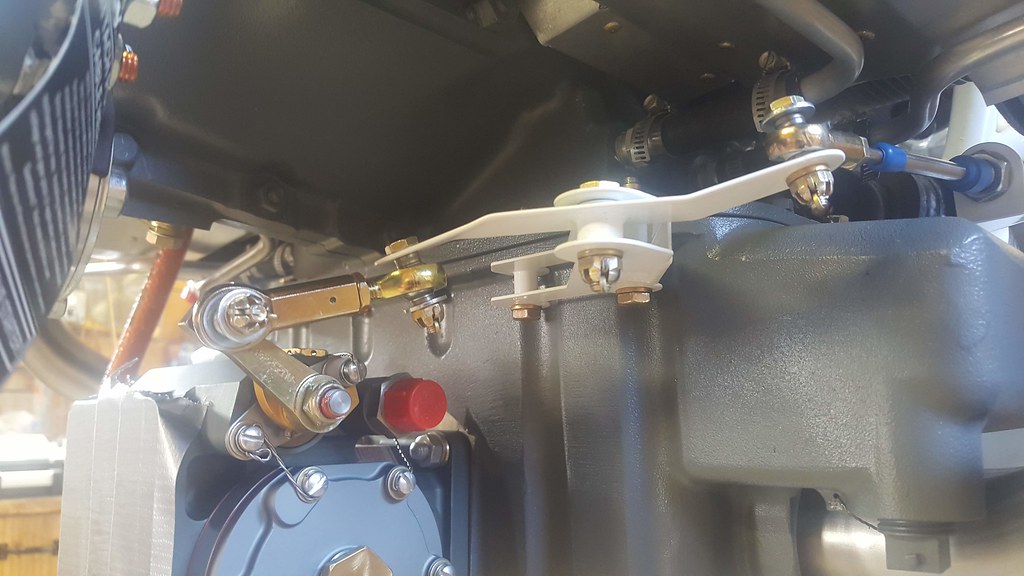

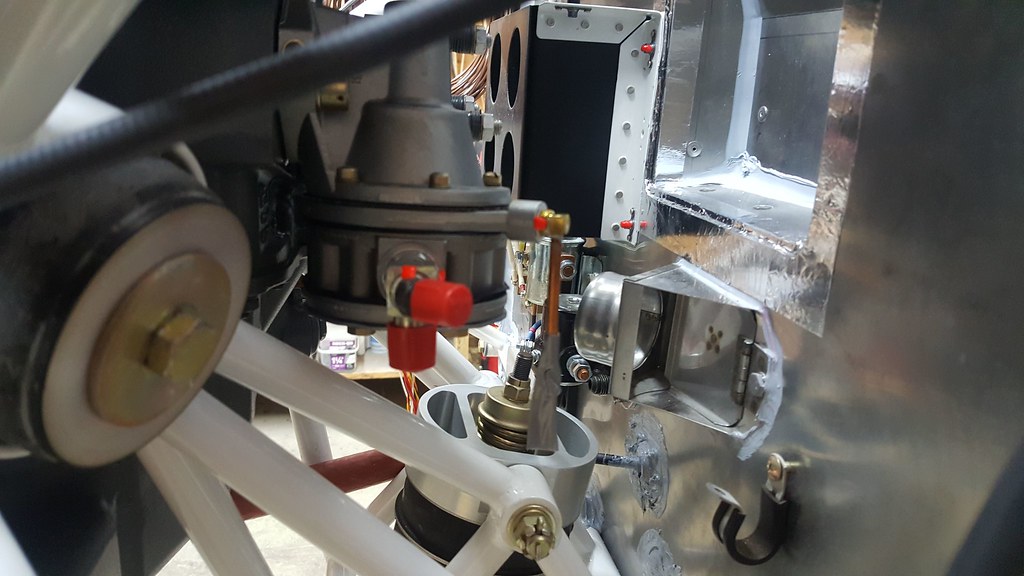

Next was the throttle cable. I have a bit of a dilemma on this one. The way Van's would have you do it it puts the cable at a pretty fair angle that seems a bit off. I increased the size of the bushing just to see how it would look. It looks better for sure but I'm torn on which one to go with. I don't like how far away the bolt is from the arm in option 2 though. I'm probably just over analyzing this.

Option 1 - Van's 3/8" bushing

20200530_153335 by Jereme Carne, on Flickr

20200530_153335 by Jereme Carne, on Flickr

Option 2 - Larger ~3/4" bushing

20200530_154430 by Jereme Carne, on Flickr

20200530_154430 by Jereme Carne, on Flickr

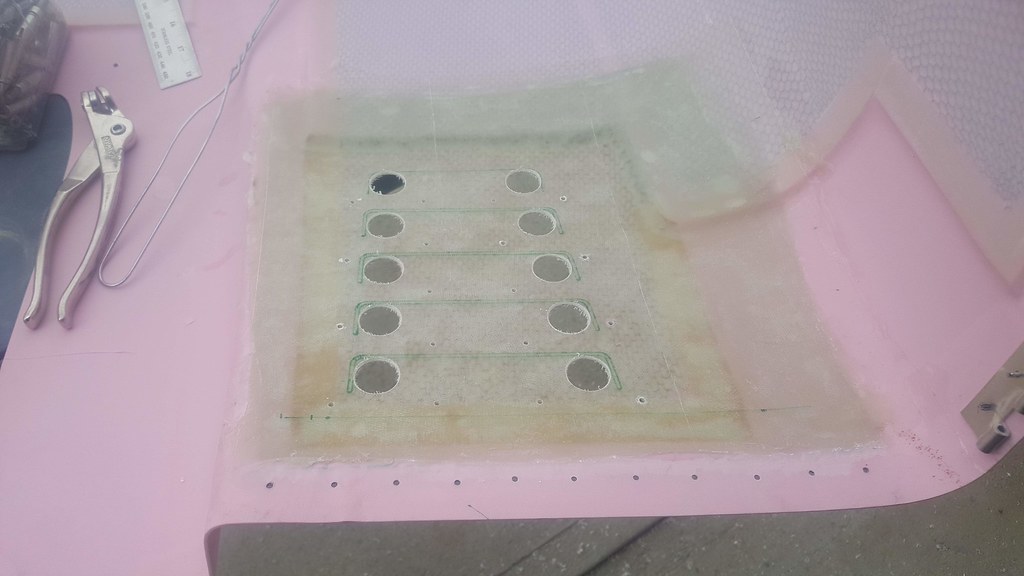

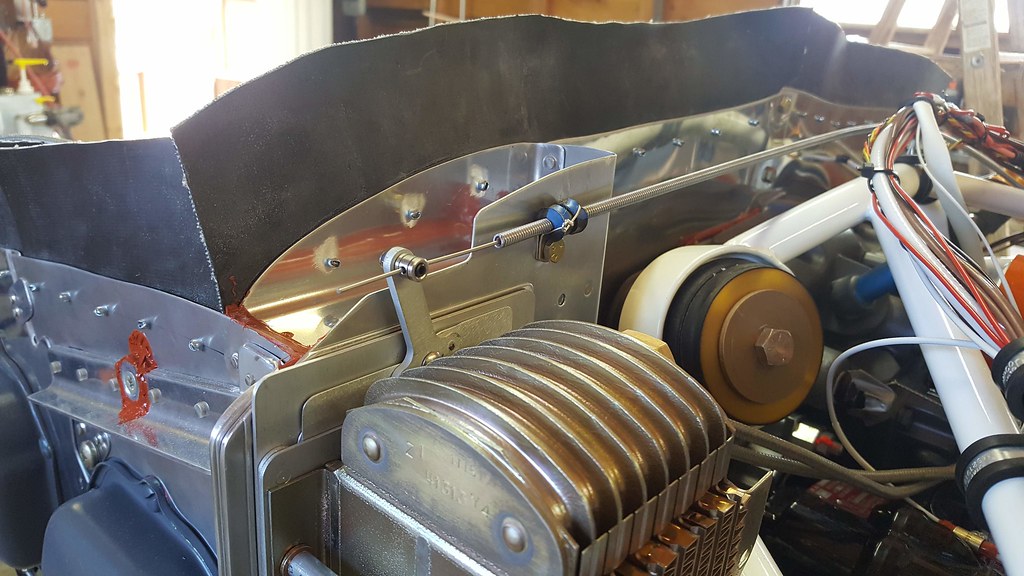

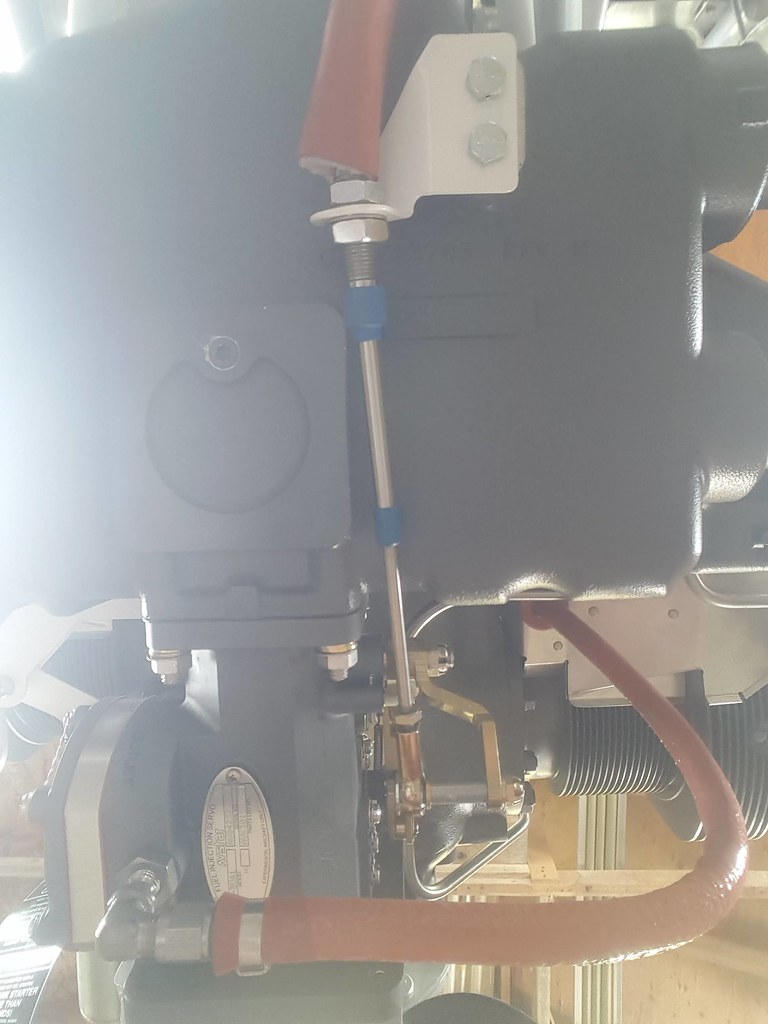

Putting the throttle cable through its paces. Gotta make sure the throttle arm is hitting the stops.

20200530_154545 by Jereme Carne, on Flickr

20200530_154545 by Jereme Carne, on Flickr

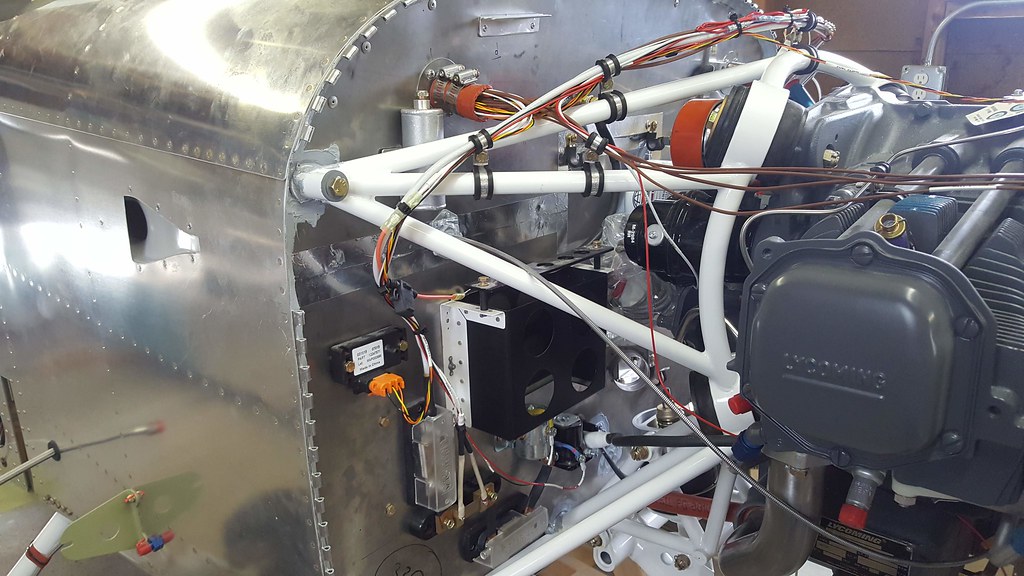

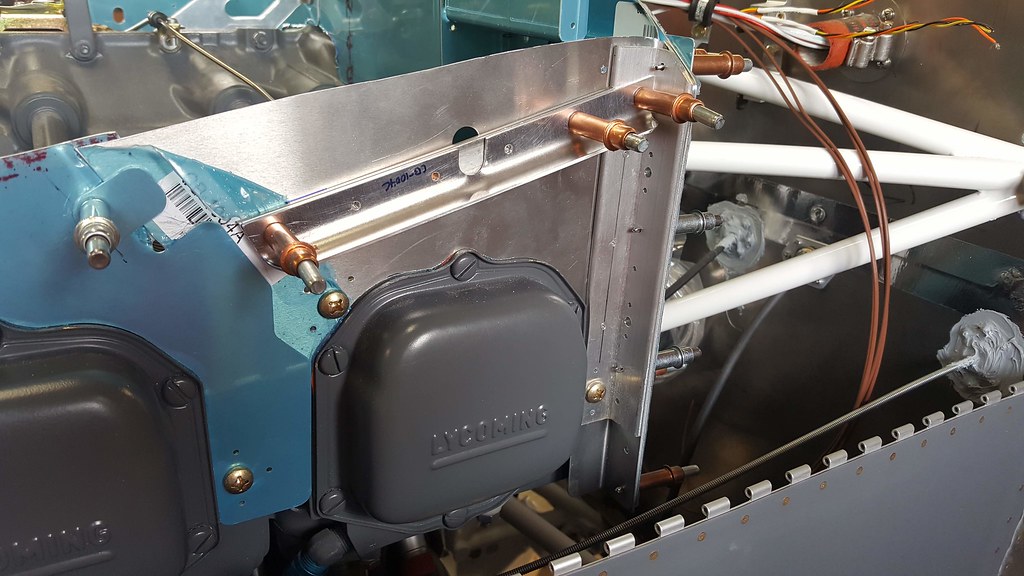

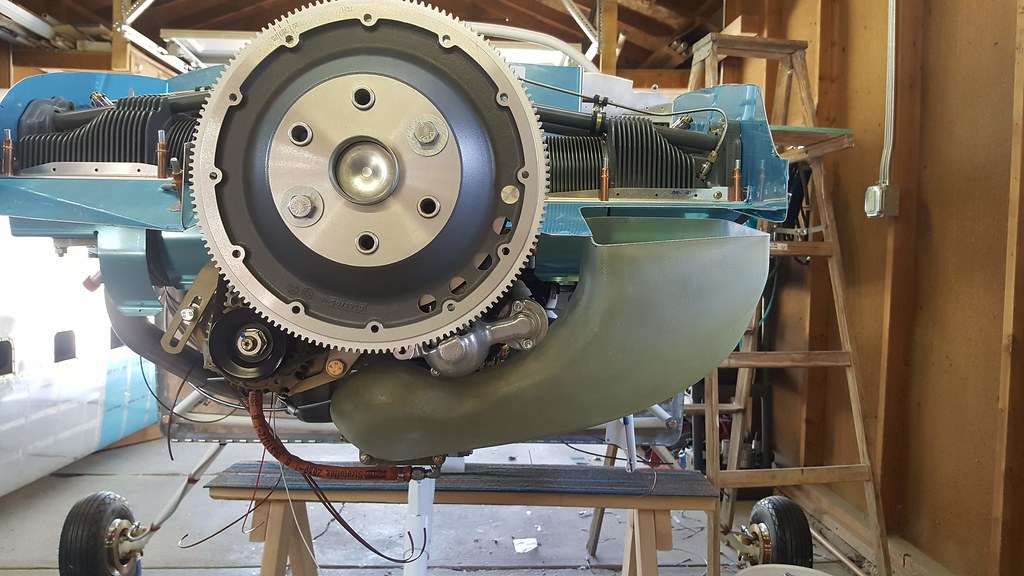

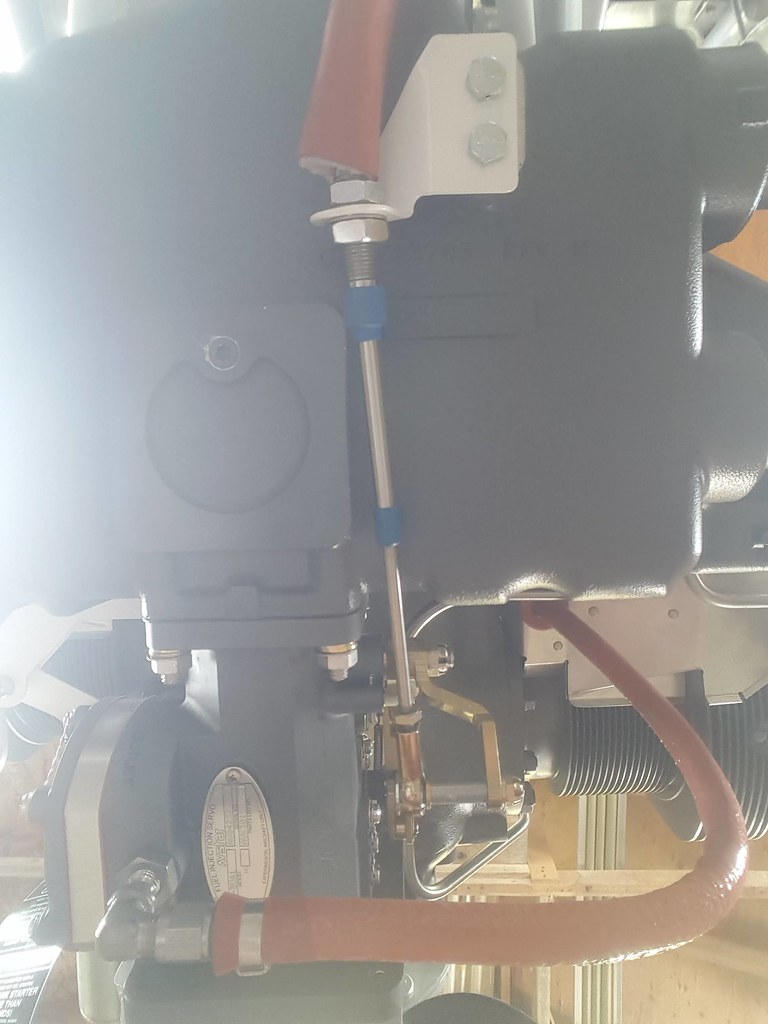

Another shot of the throttle cable. I had the firewall already drilled for the cable passthrough which is not the most ideal location with the new nosegear. It works fine though, just have to snake it around the engine mount a bit. (don't worry, the bends in the cable aren't as severe as they may look in the pic) Cable is as smooth as silk too. Bonus: I also extended the fire-sleeve a bit to serve as abrasion resistance.

20200530_184036 by Jereme Carne, on Flickr

20200530_184036 by Jereme Carne, on Flickr

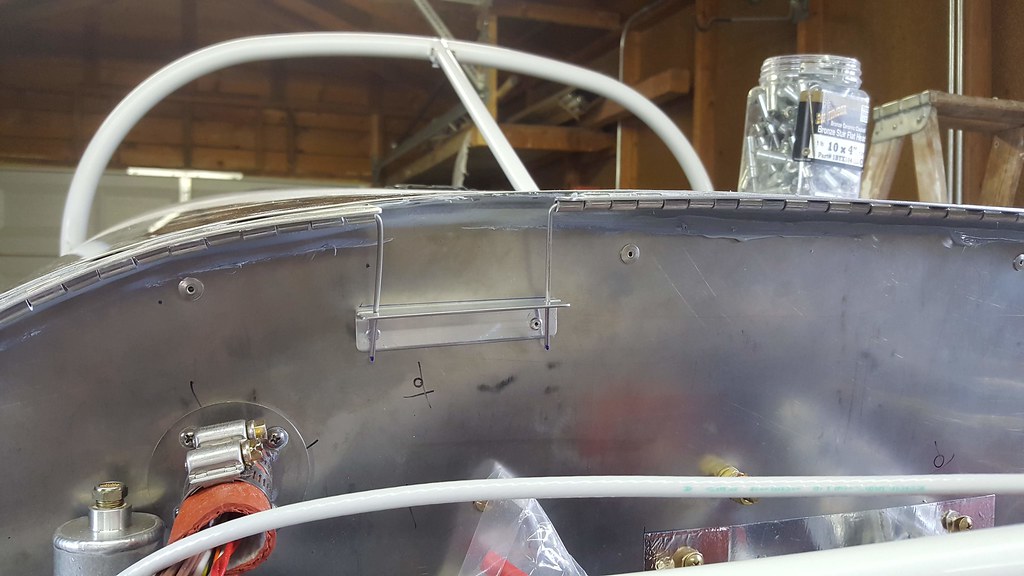

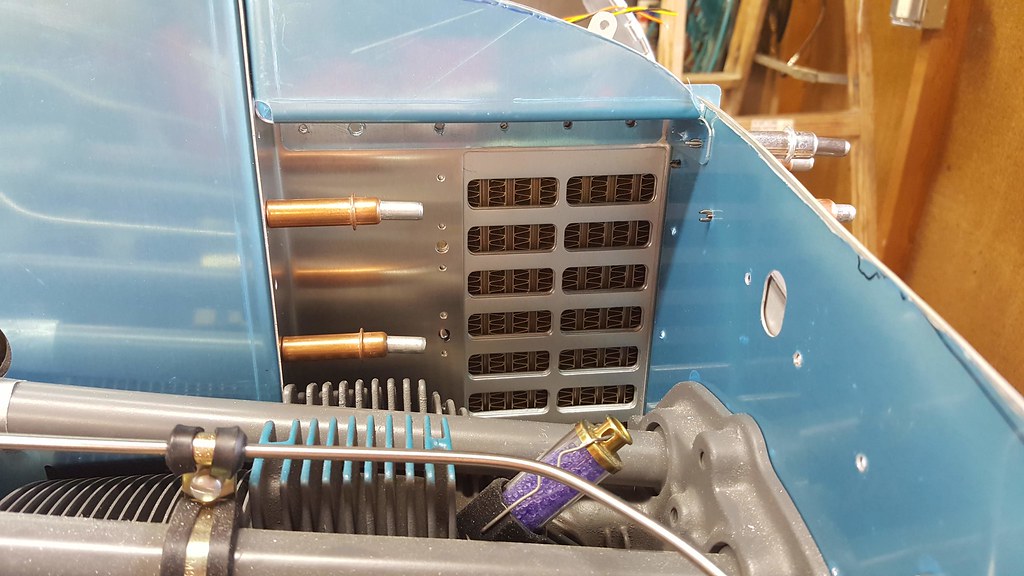

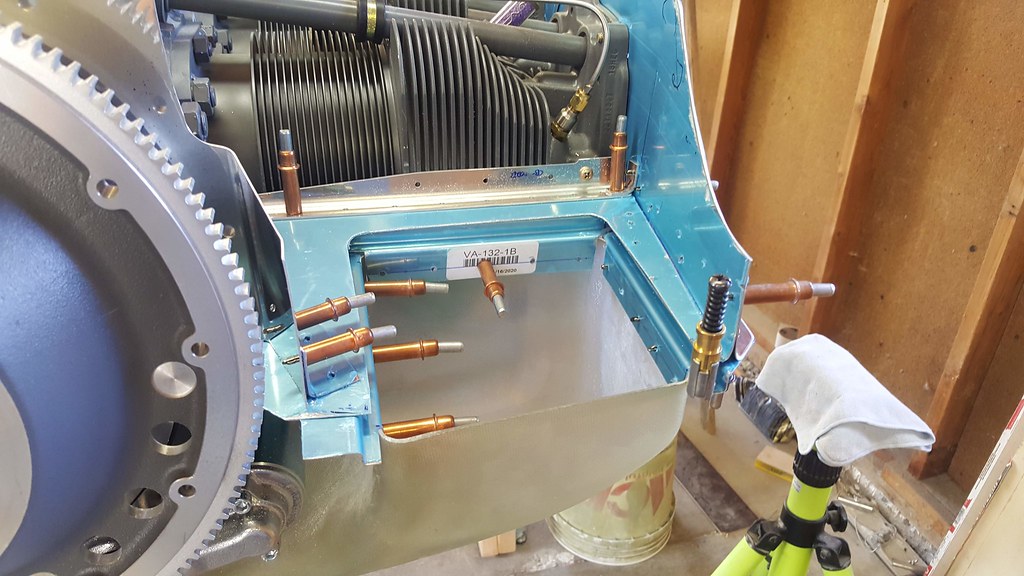

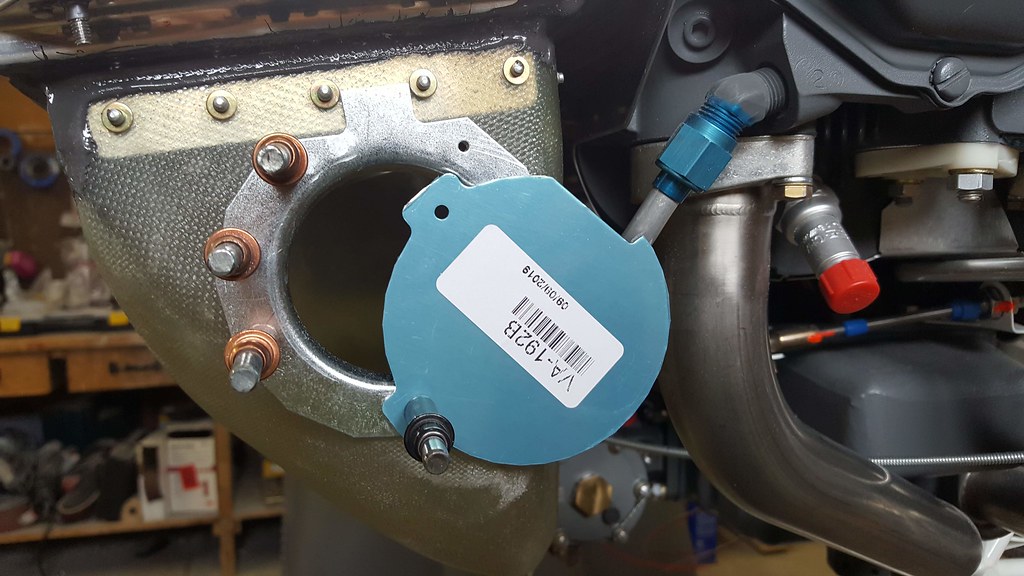

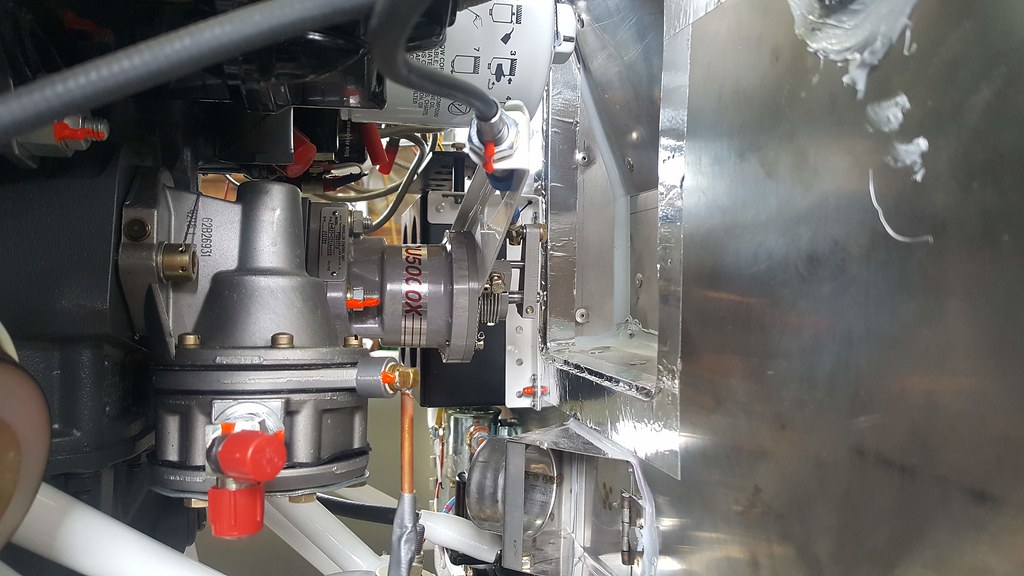

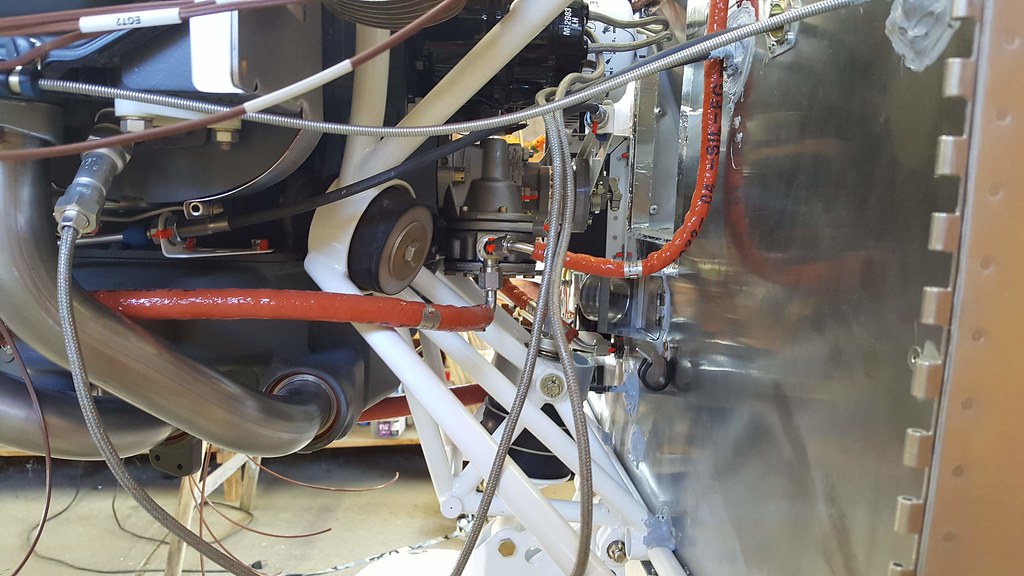

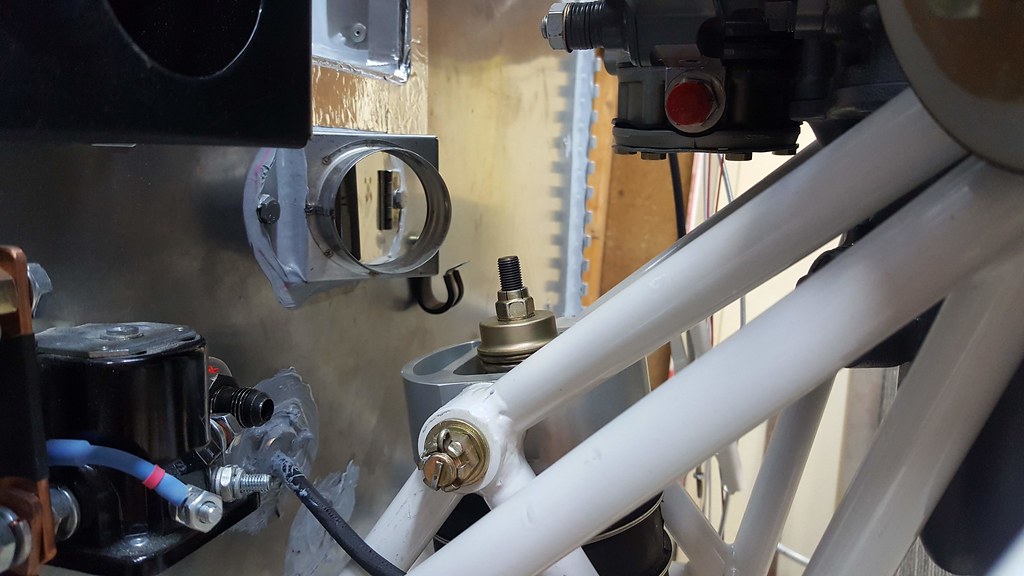

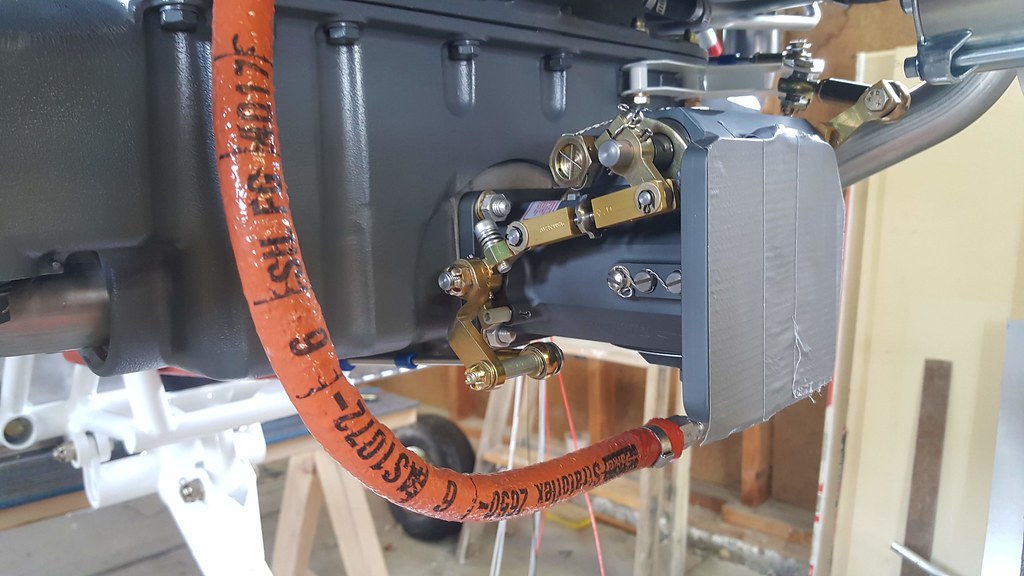

I'm debating on what to order for this fuel line. A stright fitting may result in the hose not getting out of way fast enough for the nose gear parts. A 45 fitting may rise too quickly and get in the way of the scat. A 45 rotated sideways a bit may be just the ticket.

20200530_212613 by Jereme Carne, on Flickr

20200530_212613 by Jereme Carne, on Flickr

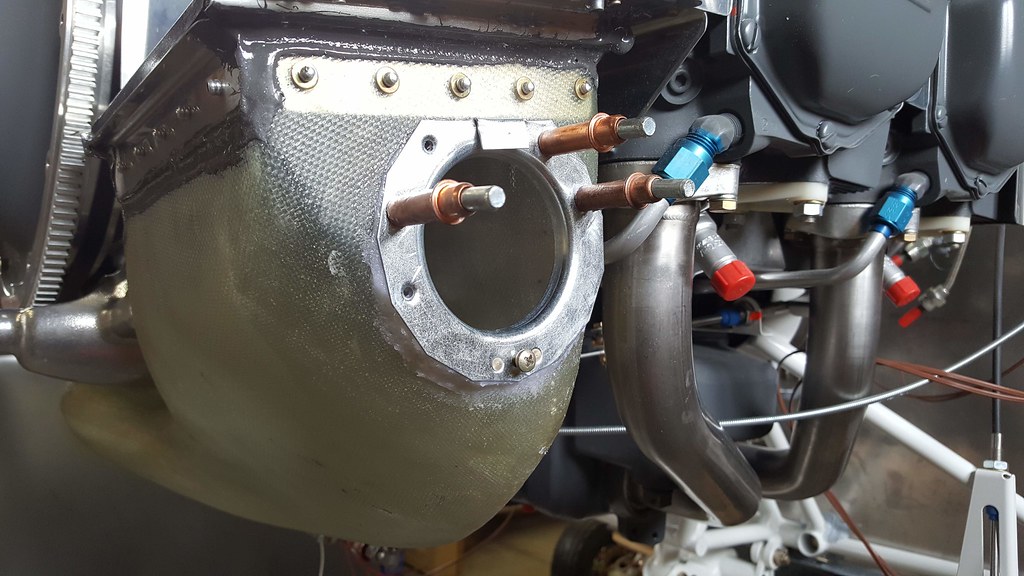

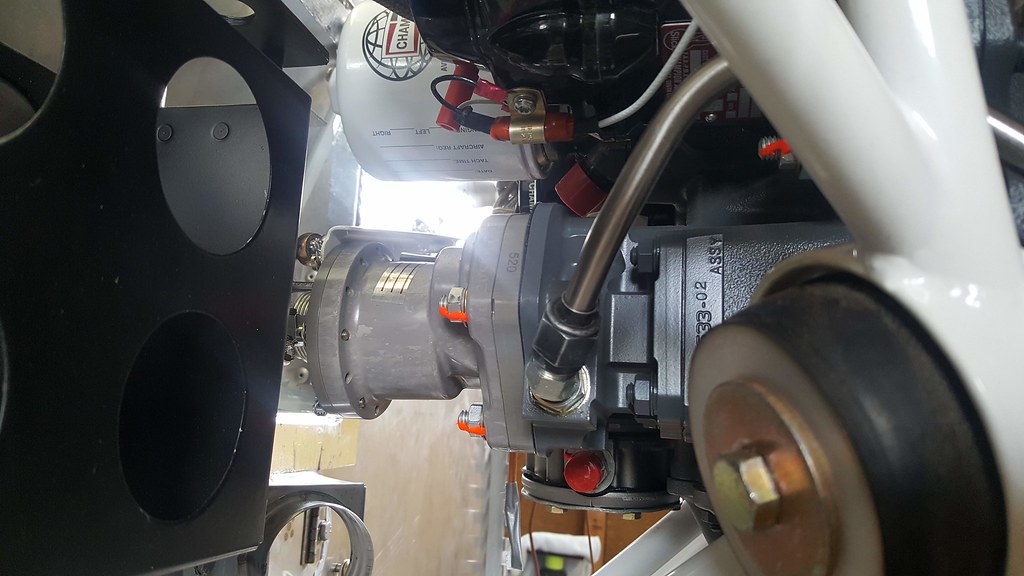

Finally, I installed the fuel pump fittings so I could take some measurements to order hoses.

20200530_213629 by Jereme Carne, on Flickr

20200530_213629 by Jereme Carne, on Flickr

As always, hope my build log is helping someone out there and let me know if anyone sees anything they don't like. Firewall forward will need the most eyes on it!

After installing the Avstar fuel servo I focused on the mixture control cable. This little Rube Goldberg contraption I think is just so cool! It works wonderfully too. It took awhile to adjust things to made sure I was hitting the stops. Just a tip for others, set the cable to the full rich stop first and the other one will take care of itself. But make sure to verify!

20200530_140159 by Jereme Carne, on Flickr

20200530_140159 by Jereme Carne, on FlickrNext was the throttle cable. I have a bit of a dilemma on this one. The way Van's would have you do it it puts the cable at a pretty fair angle that seems a bit off. I increased the size of the bushing just to see how it would look. It looks better for sure but I'm torn on which one to go with. I don't like how far away the bolt is from the arm in option 2 though. I'm probably just over analyzing this.

Option 1 - Van's 3/8" bushing

20200530_153335 by Jereme Carne, on Flickr

20200530_153335 by Jereme Carne, on FlickrOption 2 - Larger ~3/4" bushing

20200530_154430 by Jereme Carne, on Flickr

20200530_154430 by Jereme Carne, on FlickrPutting the throttle cable through its paces. Gotta make sure the throttle arm is hitting the stops.

20200530_154545 by Jereme Carne, on Flickr

20200530_154545 by Jereme Carne, on FlickrAnother shot of the throttle cable. I had the firewall already drilled for the cable passthrough which is not the most ideal location with the new nosegear. It works fine though, just have to snake it around the engine mount a bit. (don't worry, the bends in the cable aren't as severe as they may look in the pic) Cable is as smooth as silk too. Bonus: I also extended the fire-sleeve a bit to serve as abrasion resistance.

20200530_184036 by Jereme Carne, on Flickr

20200530_184036 by Jereme Carne, on FlickrI'm debating on what to order for this fuel line. A stright fitting may result in the hose not getting out of way fast enough for the nose gear parts. A 45 fitting may rise too quickly and get in the way of the scat. A 45 rotated sideways a bit may be just the ticket.

20200530_212613 by Jereme Carne, on Flickr

20200530_212613 by Jereme Carne, on FlickrFinally, I installed the fuel pump fittings so I could take some measurements to order hoses.

20200530_213629 by Jereme Carne, on Flickr

20200530_213629 by Jereme Carne, on FlickrAs always, hope my build log is helping someone out there and let me know if anyone sees anything they don't like. Firewall forward will need the most eyes on it!