Draker

Well Known Member

Well, the weather in NorCal this weekend isn't going to get very hot, so I'm going to put off the big cut. This gives me another week to agonize over the cut line on my (tipper) canopy. I can't seem to get the top of the canopy less than an inch or so from the roll bar. I've trimmed and trimmed and trimmed (probably trimmed too much) and it still doesn't rest close to the roll bar. Van's says to draw the line "when you have gotten the fit to be somewhat close". Does 1 inch count as somewhat?

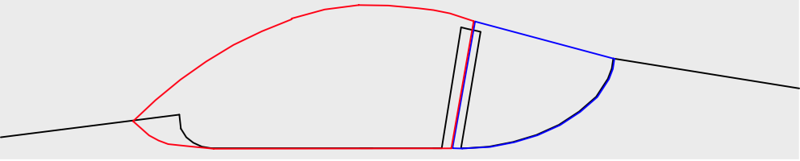

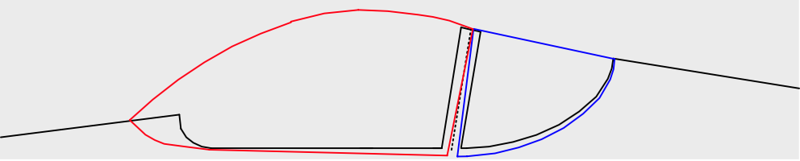

I'm worried that after the cut, when the canopy pivots down such that it can touch the roll bar, the cut line will no longer be aligned with the roll bar centerline:

Before cut:

After cut:

Am I overthinking this? I'm not sure I want to trim too much more since the existing trimming I've done has not really helped. I also don't want to put pressure on the top of the canopy to "force" it down onto the roll bar.

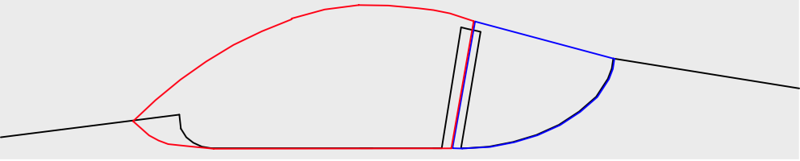

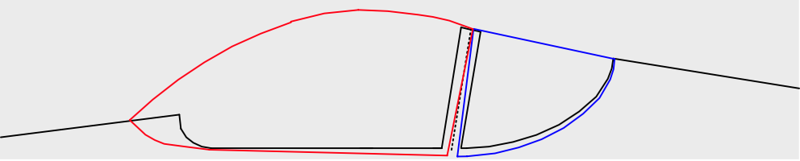

I'm worried that after the cut, when the canopy pivots down such that it can touch the roll bar, the cut line will no longer be aligned with the roll bar centerline:

Before cut:

After cut:

Am I overthinking this? I'm not sure I want to trim too much more since the existing trimming I've done has not really helped. I also don't want to put pressure on the top of the canopy to "force" it down onto the roll bar.