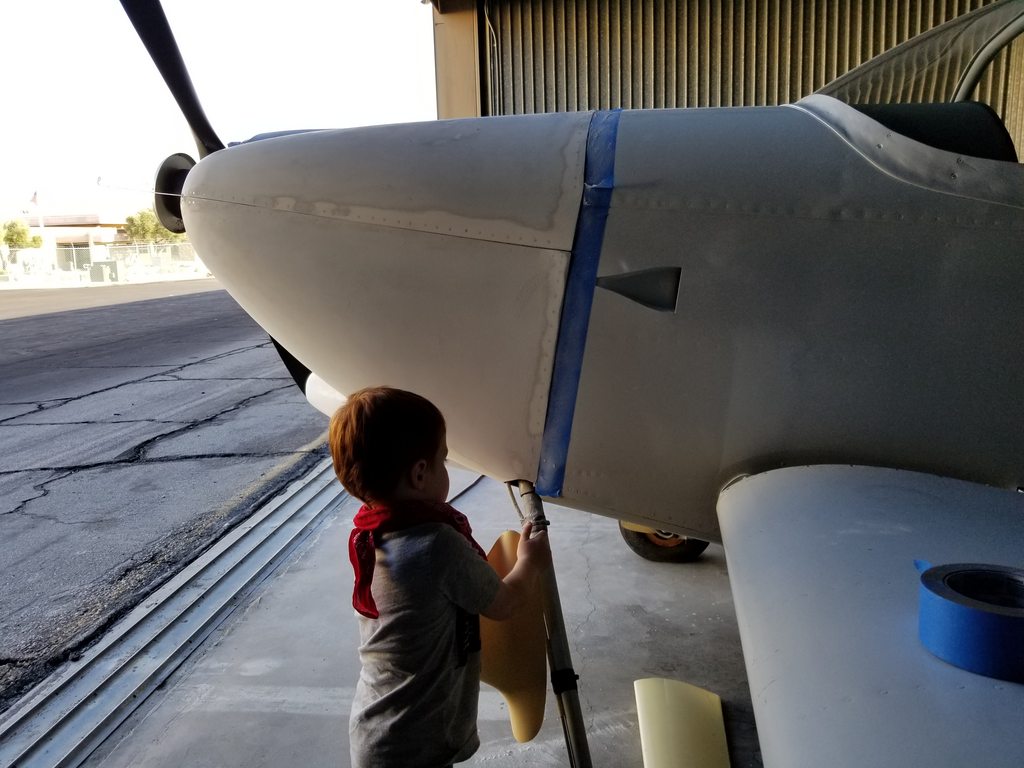

Spent another few hours at the hangar this evening.

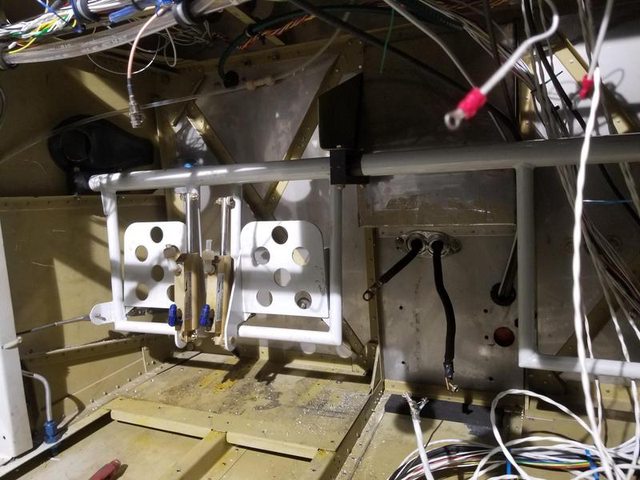

ELT is nearly wired. After that, everything is done, except fuel flow and tank senders, which I haven't fitted yet.

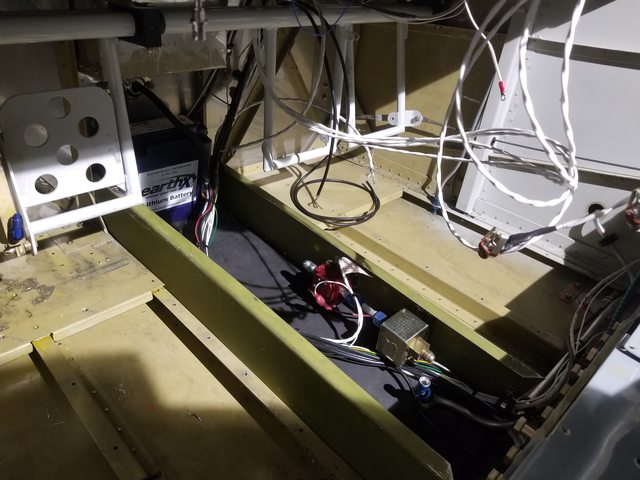

Having been through 800 iterations of the same idea, I've finally settled on what I'm doing with the floor, and how to address my centre console idea. The centre of the floor will have a small raised tunnel, similar to the transmission tunnel on a car. Inside this I will put my EarthX battery, wiring harness, fuel lines, pump and red cube.

I'd like to put the tank selector and elevator trim on a separate, standalone bracket.

Question... is it OK to use the wing spar bolts to hold this bracket in place? The bracket would span 6 of the large high-tolerance bolts at the top of the spar (three on each wing). I understand that the bolts are in shear, but don't want to discover that they're also somehow in tension, and that having a slither of 2024 sandwiched in there is not safe.

ELT is nearly wired. After that, everything is done, except fuel flow and tank senders, which I haven't fitted yet.

Having been through 800 iterations of the same idea, I've finally settled on what I'm doing with the floor, and how to address my centre console idea. The centre of the floor will have a small raised tunnel, similar to the transmission tunnel on a car. Inside this I will put my EarthX battery, wiring harness, fuel lines, pump and red cube.

I'd like to put the tank selector and elevator trim on a separate, standalone bracket.

Question... is it OK to use the wing spar bolts to hold this bracket in place? The bracket would span 6 of the large high-tolerance bolts at the top of the spar (three on each wing). I understand that the bolts are in shear, but don't want to discover that they're also somehow in tension, and that having a slither of 2024 sandwiched in there is not safe.