Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

P-mag Timing Explained

- Thread starter N941WR

- Start date

Carl Froehlich

Well Known Member

How does one wire the ignition on/off switches for pmags to allow to check to see if the internal alternator is working? 4 toggles or?

The simple way is to open the pMag breaker for this test. So just one control toggle for each pMag, and of course one breaker for each pMag.

Carl

How does one wire the ignition on/off switches for pmags to allow to check to see if the internal alternator is working? 4 toggles or?

Not by number of toggles of any switch ...

The PMAG internal generators work when engine is at 800rpm or higher.

If you set your engine to 1000rpm and remove power via a switch or breaker from the PMAG, they will continue running, confirming the generators are working.

I do this check just about every flight, one at a time.

Edit: Another confirmation that you're wired up correctly would be to set your engine to less than 750rpm and then remove the power from the PMAGs, the engine should stop.

Last edited:

Oh, I may have misunderstood your question, my bad. It seems you may have been asking what types of switches to wire up and not how to test.

Most people either use a breaker if PMAGs are installed after the fact and they don't want to modify the panel.

New builds I see a lot of folks using 3-position with the test position momentary:

https://www.steinair.com/product/s700-2-50-switch/

If you ask Brad at Emagair I think he recommends having 4 completely separate switches as I understand this setup makes it a bit easier to set initial timing.

Most people either use a breaker if PMAGs are installed after the fact and they don't want to modify the panel.

New builds I see a lot of folks using 3-position with the test position momentary:

https://www.steinair.com/product/s700-2-50-switch/

If you ask Brad at Emagair I think he recommends having 4 completely separate switches as I understand this setup makes it a bit easier to set initial timing.

Last edited:

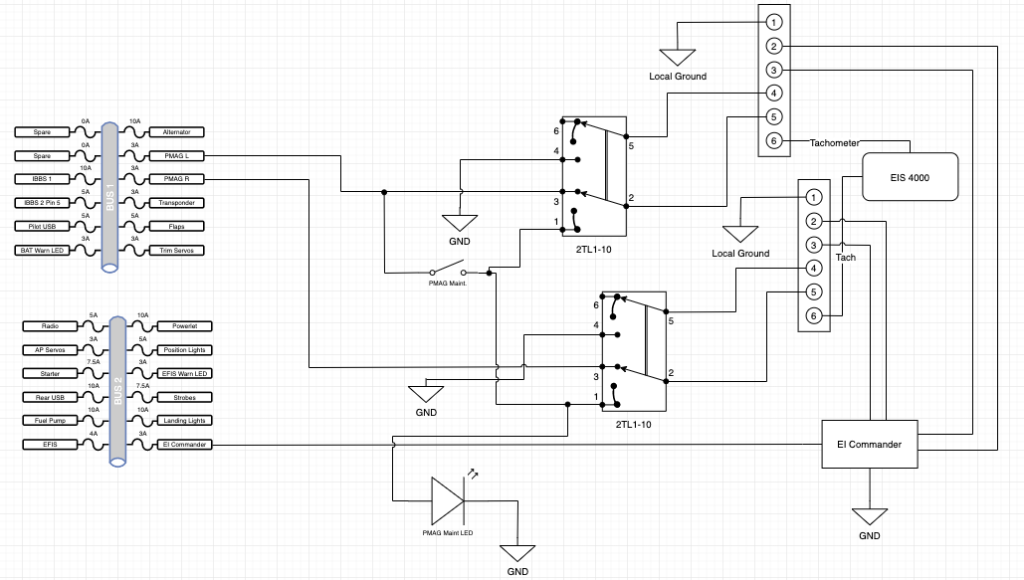

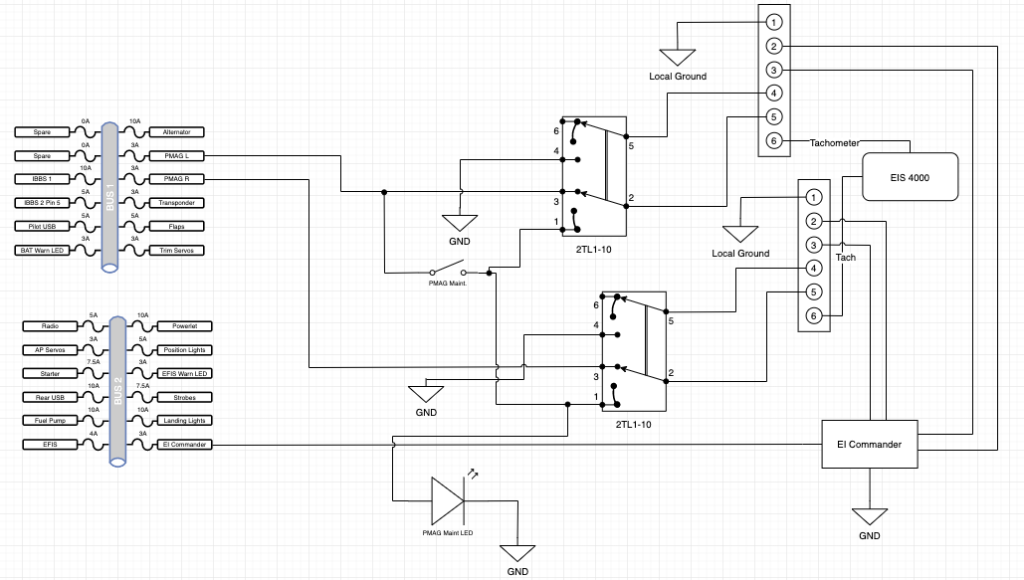

pmag wiring

Here's how I did it.

The "source" for my wiring diagrams is here:

http://www.rv8.ch/files/RV-8-HB-YMM-Wiring.drawio

You might have guessed from the filename that I used https://draw.io/ for the drawings.

How does one wire the ignition on/off switches for pmags to allow to check to see if the internal alternator is working? 4 toggles or?

Here's how I did it.

The "source" for my wiring diagrams is here:

http://www.rv8.ch/files/RV-8-HB-YMM-Wiring.drawio

You might have guessed from the filename that I used https://draw.io/ for the drawings.

Last edited:

derLuigi

Well Known Member

Here's how I did it.

edit: this post refers to an earlier version of the diagram, fixed now (see post #58)

Mickey,

I'm a bit confused by your wiring of pin 4 (the pin formerly known as p-lead). In flight the switch is in the upper position, right?

I might have a serious brainfart here but doesn't pin 4 behave the traditional way (grounded means the ignition is off - aka "kill-switch")?

Last edited:

WingnutWick

Well Known Member

So recently I had to re-install one of my PMags and I previously had the jumper out and EICAD advance shift -1.4 with max advance at 36 because jumper in was yielding way too hot CHTs even manually clicked back. I decided to try again the manual, jumper in, clocking -1.4 on this one I was reinstalling as I was told that you get the same thing as if you did it through the EICAD program and sure enough, CHTs are back to being very high! I?m not sure why there is a difference there but doing the 0-360 recommended EICAD -1.4 and 36 seems to agree a lot more with my motor than manually clocking -1.4 via the flywheel timing.

Also, correct me if I?m wrong but 1.4 isn?t a magic number when it comes manual clocking, it?s more ballpark. I think 1.4 came along because the software bit increments when using through EICAD are in 1.4 segments and 1.4 is more appropriate than -2.8. But manually clocking -2 degrees may in fact be the magic number (for example).

Also, correct me if I?m wrong but 1.4 isn?t a magic number when it comes manual clocking, it?s more ballpark. I think 1.4 came along because the software bit increments when using through EICAD are in 1.4 segments and 1.4 is more appropriate than -2.8. But manually clocking -2 degrees may in fact be the magic number (for example).

error in diagram

Amazing - you are right - my diagram is wrong. Fixed. Thanks for catching this.Mickey,

I'm a bit confused by your wiring of pin 4 (the pin formerly known as p-lead). In flight the switch is in the upper position, right?

I might have a serious brainfart here but doesn't pin 4 behave the traditional way (grounded means the ignition is off - aka "kill-switch")?

Last edited:

Carl Froehlich

Well Known Member

So recently I had to re-install one of my PMags and I previously had the jumper out and EICAD advance shift -1.4 with max advance at 36 because jumper in was yielding way too hot CHTs even manually clicked back. I decided to try again the manual, jumper in, clocking -1.4 on this one I was reinstalling as I was told that you get the same thing as if you did it through the EICAD program and sure enough, CHTs are back to being very high! I?m not sure why there is a difference there but doing the 0-360 recommended EICAD -1.4 and 36 seems to agree a lot more with my motor than manually clocking -1.4 via the flywheel timing.

Also, correct me if I?m wrong but 1.4 isn?t a magic number when it comes manual clocking, it?s more ballpark. I think 1.4 came along because the software bit increments when using through EICAD are in 1.4 segments and 1.4 is more appropriate than -2.8. But manually clocking -2 degrees may in fact be the magic number (for example).

What are the CHTs?

Perhaps a base test would resolve this. For both pMags back out the EICAD shift (as in put the pMag back to stock). Time the engine per the installation instructions (TDC for a parallel valve or 5 degrees ATDC for an angle valve engine), pMag with jumper in.

See if that solves your issue.

Carl

Pmag wiring

Couple of thoughts.

1. Turning the prop with pmags will result in a a full energy spark if there is any chance of a pmag being active. So having two switches - the kill switch and the power switch as separate switches for each pmag and having each power switch as a lighted switch may be a way to have a safer system.

2. Powering each backup Pmag power from the endurance bus through separated circuit breakers and switches allows a simpler more direct mag check during pre- takeoff checks. Run up to 1700 rpm Switch one kill switch then switch off the opposite pmag power. Repeat for the others pmag. Retard throttle to below 800 and switch off backup power to each pmag in turn and observe rpm drop.

Having the master power switch on while working on the plane, having a failed kill switch and turning the prop ( even slowly) could be a killer if a pmag is inadvertently powered.

KT

Amazing - you are right - my diagram is wrong. Fixed. Thanks for catching this.

Couple of thoughts.

1. Turning the prop with pmags will result in a a full energy spark if there is any chance of a pmag being active. So having two switches - the kill switch and the power switch as separate switches for each pmag and having each power switch as a lighted switch may be a way to have a safer system.

2. Powering each backup Pmag power from the endurance bus through separated circuit breakers and switches allows a simpler more direct mag check during pre- takeoff checks. Run up to 1700 rpm Switch one kill switch then switch off the opposite pmag power. Repeat for the others pmag. Retard throttle to below 800 and switch off backup power to each pmag in turn and observe rpm drop.

Having the master power switch on while working on the plane, having a failed kill switch and turning the prop ( even slowly) could be a killer if a pmag is inadvertently powered.

KT

Axel, thank you for the picture!

This is a great picture of our new EICommander EIC32 that Axel posted on his Fast Back thread.

I am writing the following to help explain how the timing should be set on engines running P-mags.

This seem to be especially important for those running angle valve engines (IO-360, 390, & 400's).

The following assumes the P-mag timing marks are set at the TDC. All examples for standard 8.5:1 compression parallel valve engines. Below will be some numbers for angle valve engines.

Everything I describe below can be configured with either an EICoimmander, with the EICAD program available from Emag Ignitions, or by clocking the ignitions as described in the Emag Electronic Ignition Installation & Operating Guide available here.

Displayed in this picture it the timing configuration page from the new EICommander EIC32. This is a custom "C" configuration that Axel has made and sent to his P-mags.

First, the standard P-mag "A" jumper in configuration has a the following settings:

RPM Max (Rev limiter): 3328 RPM's

Advance Shift: 0 - This equates to 26.6 degrees before TDC.

Max Advance: 35.0 degrees before TDC.

Max RPM;

Axel reduced the point where the P-mags will stop firing to 2816 RPM's. This is good because should he have a prop governor failure, the P-mags will limit the overspeed to this number and help him avoid an engine overhaul.

Advance Shift:

By setting the Advance Shift to a -1.4 degrees, the high power timing setting will be 25.2 degrees BTC.

Max Advance:

The Max Advance is exactly what is sounds like. As the manifold pressure drops off with altitude and throttle setting, this is limits how far the P-mags will advance.

RMSD:

Run Mode Start Delay allows the engine to delay firing the sparkplugs for a set number of revolutions. Zero is the desired setting. If you change this to two (2), the engine will make two complete revolutions prior to firing the sparkplugs. If this is set to any value other than zero (0), the engine will pump raw fuel out the exhaust ports, which will light off with a bang once the ignition comes on line. Thus we highly recommend it be left at zero (0).

LED:

The allows you to turn on and off the external LED. Leaving it set to "SENS" allows you to see the LED turn red, yellow, and green as required to set the timing. In the newer EIC32, we do not allow this to be changed.

A few comments about P-mag configurations:

1. We have not heard of any Lycomings where the P-mags should be run on the "B curve" (no jumper). The "B Curve" starts firing the ignitions at 30.8 degrees BTC and advances out to 39.2 degrees.

2. The configuration Axel has selected appears to work very well for Parallel valve engines. We have enough experience with it to say that in a typical installation, this will reduce the CHT's 10 to 20 degrees F and increase speed a few knots over the standard "A" - jumper in configuration.

3. If you run an angle valve engine (IO-360, 390, 400, etc.) that requires a 20 degree timing, neither the "A" nor "B" curve should be used when the P-mag's timing mark is set to TDC. Using either of these configurations could damage your engine.

There are three ways to set the timing for these engines. One is to "clock" the ignitions, similar to how the timing is set with a standard magneto. Contact Emag Ignitions for details.

The other two options are to create a custom configuration with either an EICommander or the free EICAD program from Emag Ignitions.

Again, this assumes you have set your timing mark to Top Dead Center.

Advance Shift:

-7.0 will cause the P-mag to fire at 19.6 degrees BTC during high power operations such as takeoffs.

Max Advance:

29.4 will limit the maximum, lower power advance to this value.

These engines should never be set at TDC and then run with either the jumper in or jumper out. Either of these configurations may damage your engine when the TDC mark is set to Top Dead Center.

CHT cooling on angle valve engines seems to be much better than parallel valve engines. Do not take acceptable CHT's as an indication that all is OK with your engine while running excessive advance in your angle valve engine.

If you have a high compression engine, consult your engine builder for the proper timing advance.

As always, feel free to contact me off line, if you have questions. I am more than happy to help protect you and your engine. I don't care if you are an EICommander customer or not, I am happy to help.

Either Angle or Parallel Valve engines:

Finally, if you have a new engine, or a newly overhauled engine, I recommend you set the Max Advance number to equal your high power timing number for the first 10 hours +/-. This way, if you experience high CHT's for the first ten hours or so, you know the issue isn't a result of your timing advance and is probably the result of a baffling leak. After your CHT's drop, then change the Max Advance number as appropriate for your engine.

Clocking your P-mags:

Emag Ignition's preferred method of setting the timing is to not use the EICAD program but rather "clock" the timing mark. This achieves the same things as adjusting the internal timing values with either the EICAD program or the EICommander.

This does not require you to purchase any hardware (USB to serial connectors, EICommanader, etc.) or install the EICAD program on your computer. It accomplishes the same thing by moving the initial firing point and should be accomplished with the jump installed between P-mag pins 2 and 3.

Remember, the goal is to fire the spark plugs at the point recommended by your engine builder, any way this is accomplished is beneficial to you and your engine.

DB9 Connectors:

The following image is what I recommend to builders who install P-mags and plan on adjusting them with either the EICAD program or adding an EICommander later on (If you are going to start with an EICommander, wire them as recommended in the EIC manual. As stated above, it is not required, if you plan on "clocking" the ignitions to achieve optimal timing. This will allow you to connect to the P-mags with a PC from inside the cockpit and should you later decide to install an EICommander, you can make a simple wiring harness to join both P-mags to the EIC.

"No jumper" is depicted because the drawing assumes you are going to customize the P-mag configuration. If you elect to run the standard "A Curve", place the jumper at the DB9 plug.

Hand Proping:

Do not hand prop your plane, unless you have been trained in the fine art of hand propping.

If you expect to need to hand prop your aircraft, contact me off list (include your email address), and I will send you a wiring diagram on how to wire in a 9 volt battery to one P-mag.

Moderators, I'll suggest Bill's post should be a sticky. The suggested base timing and max advance values (Post #1) are well supported.

Parallel valve: base 25.2 degrees BTDC, max 33.6 (25 max 34)

Angle valve: base 19.6 BTDC, max 29.4 (20 max 29)

Although the post describes how to achieve those settings with an EI Commander or EICAD, the stated values apply to any ignition brand...and we have folks out there doing really dumb things with timing.

Gents: old thread but packed with good info. I pulled my jumper and set the parallel valve values through the software last night. Interested to see a reduction in CHT!

Just wanted to say thanks for sharing the info!

Major post edits below in red

This seems to be misleading because of the following statement: This is actually not misleading at all, there's just a little bit of information missing. See below:

My understanding is that even with the EICommander, you can't modify the "A" curve, which means all the math starts at 30.8° BTDC. So Axel's timing should have actually been 29.4° BTDC?

I was looking through a bunch of old photos and came across the EICAD screenshot I took when I changed the tach output from 2 to 1 Pulse per Rev. The "B" curve advance shift is set to +4.2 from the factory. This makes the math work out. With advance shift set to -1.4, you would be at 25.2° BTDC, just like the original post said.

Assuming (I could totally be wrong here) that we're modifying the "B" curve, shouldn't -7 advance shift actually make 23.8° BTDC?

Nope. He was right - see my red corrections above.

Long story short - I've been chasing CHTs for a hot minute (no pun intended). I thought it was my cowling (which definitely still needs work), but I've done a ton of work on my baffles and still could not control temps even in the winter without step climbs WAY above Vy. My next step was to start from scratch on a new cowl with inlets like DanH.

I found this thread again while researching about my broken ignition wires causing radio interference and I think I've accidentally been rocking 29.4° BTDC base timing on my 160hp O-320 (-1.4 advance shift programmed via EICAD, dual pmags set to TDC) . If that's right, it seems excessive. After I changed my plug wires, I went ahead and retarded my timing by 2 flywheel teeth, or about 4.8 degrees. Magically I was able to climb out at Vx with controllable CHTs. Power is definitely down a little, so I'm going to advance the timing another 1/2 tooth before I fly next to see how that does with power and temps. If that works then I'll set them back to TDC and then adjust the numbers in the EICAD to make my "B" curve match.

Ok, this is wrong. I've been flying around at approximately 20.5° BTDC base timing and 29° BTDC max advance. I've really been enjoying the cruise timing so I'm going to keep that but I'm going to bring my base timing back up to around 24° BTDC and see how temperatures do. Looks like I'm back to looking at an upper cowling rework.

I left my original post and made the corrections like this in case someone else is dumb like me and needs to see why the original post is actually correct. Thanks for coming to my TED Talk.

First, the standard P-mag "A" jumper in configuration has a the following settings:

RPM Max (Rev limiter): 3328 RPM's

Advance Shift: 0 - This equates to 26.6 degrees before TDC.

Max Advance: 35.0 degrees before TDC.

<snip>

Advance Shift:

By setting the Advance Shift to a -1.4 degrees, the high power timing setting will be 25.2 degrees BTC.

This seems to be misleading because of the following statement: This is actually not misleading at all, there's just a little bit of information missing. See below:

A few comments about P-mag configurations:

1. We have not heard of any Lycomings where the P-mags should be run on the "B curve" (no jumper). The "B Curve" starts firing the ignitions at 30.8 degrees BTC and advances out to 39.2 degrees.

My understanding is that even with the EICommander, you can't modify the "A" curve, which means all the math starts at 30.8° BTDC. So Axel's timing should have actually been 29.4° BTDC?

I was looking through a bunch of old photos and came across the EICAD screenshot I took when I changed the tach output from 2 to 1 Pulse per Rev. The "B" curve advance shift is set to +4.2 from the factory. This makes the math work out. With advance shift set to -1.4, you would be at 25.2° BTDC, just like the original post said.

this seems to support my thoughts above.2. The configuration Axel has selected appears to work very well for Parallel valve engines. We have enough experience with it to say that in a typical installation, this will reduce the CHT's 10 to 20 degrees F and increase speed a few knots over the standard "A" - jumper in configuration.

3. If you run an angle valve engine (IO-360, 390, 400, etc.) that requires a 20 degree timing, neither the "A" nor "B" curve should be used when the P-mag's timing mark is set to TDC.

<snip>

this assumes you have set your timing mark to Top Dead Center.

Advance Shift:

-7.0 will cause the P-mag to fire at 19.6 degrees BTC during high power operations such as takeoffs.

Assuming (I could totally be wrong here) that we're modifying the "B" curve, shouldn't -7 advance shift actually make 23.8° BTDC?

Nope. He was right - see my red corrections above.

Long story short - I've been chasing CHTs for a hot minute (no pun intended). I thought it was my cowling (which definitely still needs work), but I've done a ton of work on my baffles and still could not control temps even in the winter without step climbs WAY above Vy. My next step was to start from scratch on a new cowl with inlets like DanH.

I found this thread again while researching about my broken ignition wires causing radio interference and I think I've accidentally been rocking 29.4° BTDC base timing on my 160hp O-320 (-1.4 advance shift programmed via EICAD, dual pmags set to TDC) . If that's right, it seems excessive. After I changed my plug wires, I went ahead and retarded my timing by 2 flywheel teeth, or about 4.8 degrees. Magically I was able to climb out at Vx with controllable CHTs. Power is definitely down a little, so I'm going to advance the timing another 1/2 tooth before I fly next to see how that does with power and temps. If that works then I'll set them back to TDC and then adjust the numbers in the EICAD to make my "B" curve match.

Ok, this is wrong. I've been flying around at approximately 20.5° BTDC base timing and 29° BTDC max advance. I've really been enjoying the cruise timing so I'm going to keep that but I'm going to bring my base timing back up to around 24° BTDC and see how temperatures do. Looks like I'm back to looking at an upper cowling rework.

I left my original post and made the corrections like this in case someone else is dumb like me and needs to see why the original post is actually correct. Thanks for coming to my TED Talk.

Last edited:

Toddsanderson

Well Known Member

Hello,

Thank you for this information. 1 question: I have an io-390EXP (not 119) and it runs perfectly. 380 F in the climb max and 290-320F in cruise. Roughly 9.5GPH yielding 168TAS in my 14A at 10500Ft using WOT and 2500 RPM when 20-30FDLOP. I have not checked timing yet, but will do so on my condition inspection coming up. If I want to reduce max power and cruise timing using the jumper between pins 2&3 does the jumper stay in place after timing or is it removed once timing is accomplished?

Thank you for this information. 1 question: I have an io-390EXP (not 119) and it runs perfectly. 380 F in the climb max and 290-320F in cruise. Roughly 9.5GPH yielding 168TAS in my 14A at 10500Ft using WOT and 2500 RPM when 20-30FDLOP. I have not checked timing yet, but will do so on my condition inspection coming up. If I want to reduce max power and cruise timing using the jumper between pins 2&3 does the jumper stay in place after timing or is it removed once timing is accomplished?

Carl Froehlich

Well Known Member

Hello,

Thank you for this information. 1 question: I have an io-390EXP (not 119) and it runs perfectly. 380 F in the climb max and 290-320F in cruise. Roughly 9.5GPH yielding 168TAS in my 14A at 10500Ft using WOT and 2500 RPM when 20-30FDLOP. I have not checked timing yet, but will do so on my condition inspection coming up. If I want to reduce max power and cruise timing using the jumper between pins 2&3 does the jumper stay in place after timing or is it removed once timing is accomplished?

You need to decide on what timing curve you want. For this engine I ran an RV-14A engine with both jumper in and out. The engine was much happier with jumper in (max 9 degrees of advance). If you have been running jumper out and have engine performance as you list, I suspect your base timing is way off. For that fuel flow and altitude you should see higher speeds.

Side note. For the four cylinder pMag you can wire the jumper to a switch on the panel to select between jumper in and out, but this only works before engine start. You cannot change after engine start. I did this on my first build but never used the switch - so it was eliminated on builds after that. On the six cylinder pMag there is option to select base timing at any point in engine operation.

I suggest:

- Set base timing at 20 degrees BTDC. Do this by setting the pMag timing at 5 degrees ATDC.

- Run Jumper in. This will provide a timing curve between 20 degrees BTDC (high manifold pressure, low altitude, max power) and 29 degrees BTDC (low MP, high altitude).

In the RV-14A I did this with CHTs were less than 350 in cruise, and below 400 degree in climb.

CarL

KatanaPilot

Well Known Member

In the RV-14A I did this with CHTs were less than 350 in cruise, and below 400 degree in climb.

CarL

Aren’t those CHT’s high for an IO-390? My son and I just ferried an RV-14A from Minnesota to Denver. OAT at 8000’ was 86 degrees (yes eighty six - it was brutal). Never saw CHT’s above 360 during full power climbs (2600 RPM) and when running LOP (using SDS LOP switch) at 24 squared for cruise - all CHT’s were 300 or below and oil temp decreased to 185. TAS of around 160 at 9 gph.

Can’t help but wonder if the pMag curve is a bit aggressive especially for an AV engine.

Toddsanderson

Well Known Member

Thank you Carl. I took some pics under the cowl and the jumper is in place already. I will verify the base timing when we do the condition inspection. My plane is slightly slower due to it's heavier weight with dual alts, heavy interior, panel, etc. I also have an airflow systems A/C system that adds weight and maybe a 2 knot penalty for the condenser scoop.

When checking timing it will be interesting to see what I come up with. The plane starts easily hot or cold and max CHTs in the climb never hit 380 and in cruise they are 290-320, so I would initially think that my timing is conservatively retarded past the TDC mark. Other than maybe slightly higher fuel burn and maybe slightly slower speeds it runs perfectly, so I hate to change it, but I have plenty of CHT available, so I might get a little more performance out of the engine with advancing the timing a bit.

When checking timing it will be interesting to see what I come up with. The plane starts easily hot or cold and max CHTs in the climb never hit 380 and in cruise they are 290-320, so I would initially think that my timing is conservatively retarded past the TDC mark. Other than maybe slightly higher fuel burn and maybe slightly slower speeds it runs perfectly, so I hate to change it, but I have plenty of CHT available, so I might get a little more performance out of the engine with advancing the timing a bit.

Carl Froehlich

Well Known Member

Aren’t those CHT’s high for an IO-390? My son and I just ferried an RV-14A from Minnesota to Denver. OAT at 8000’ was 86 degrees (yes eighty six - it was brutal). Never saw CHT’s above 360 during full power climbs (2600 RPM) and when running LOP (using SDS LOP switch) at 24 squared for cruise - all CHT’s were 300 or below and oil temp decreased to 185. TAS of around 160 at 9 gph.

Can’t help but wonder if the pMag curve is a bit aggressive especially for an AV engine.

Perhaps you are running too LOP. Again, assuming a standard build and Hartzell two blade BAF prop I would expect TAS higher than 160 at that altitude and that fuel burn.

No - CHTs were just fine. I suggest you review the Mike Busch article on keeping CHTs above 350 to mitigate stuck valve issues when burning 100LL:

https://resources.savvyaviation.com...ticles_aopa/AOPA_2020-07_why-valves-stick.pdf

I tend to run my IO-360-M1B (dual pMags) just a little LOP to keep CHTs up to ~350, and close to peak during the winter. I also note that going much beyond 20 degrees LOP engine power falls off faster than fuel burn, so overall efficiency declines.

No, I do not consider the pMag curve too aggressive (jumper in). With over 2000 hours on pMags (IO-360, IO-390 and IO-540 engines) and a lot of data taking, I can state this with some confidence. I’ll never convince the “SDS or nothing” group so I’ll not attempt it.

Carl

Jetmart

Well Known Member

I suggest:

- Set base timing at 20 degrees BTDC. Do this by setting the pMag timing at 5 degrees ATDC.

- Run Jumper in. This will provide a timing curve between 20 degrees BTDC (high manifold pressure, low altitude, max power) and 29 degrees BTDC (low MP, high altitude).

In the RV-14A I did this with CHTs were less than 350 in cruise, and below 400 degree in climb.

CarL

Carl,

Can you explain what base timing is and how you would set it?

I have my pMag timing set at 5 degrees ATDC.

Toddsanderson

Well Known Member

Carl,

Can you explain what base timing is and how you would set it?

I have my pMag timing set at 5 degrees ATDC.

You already have base timing set at 20 automatically if you have the jumper installed and timing set at 5ATDC. The jumper takes it down roughly from 30 to 25 and your manual adjustment at the flywheel takes it down another 5 degrees which puts you at 20