The best (i.e. most recent) data for air cooled engine design is probably found with the SAE. I'm not a member and not curious enough to spend non-member money for SAE books.

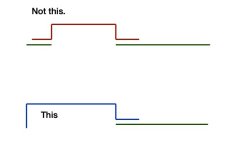

Heat transfer from metal to air is governed by temperature delta. The air entering a full wrap baffle is at ambient temperature, so heat transfer from the hot metal is high. Further around the cylinder the air is now much warmer, and heat transfer is lower. The result is less and less cooling as the air proceeds further around the cylinder.

There's an early NACA work illustrating the issue. See Table 1 and Fig 2:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20090014186_2009013404.pdf

It is interesting to note that our stock baffle scheme is something like Fig 2a; small exit radius, close entrance width, no exit duct...the worst configuration tested in terms of uneven cooling and energy loss.

To be fair the deformation of the cylinder from perfectly round to some unknown shape may be minimal. I don't know. It should also be noted that there is a difference between cooling cylinders and cooling cylinder heads. Obviously the fin area is shifted toward the exhaust side, and aluminum has a far higher ability to transfer heat by conduction as compared the steel barrels.

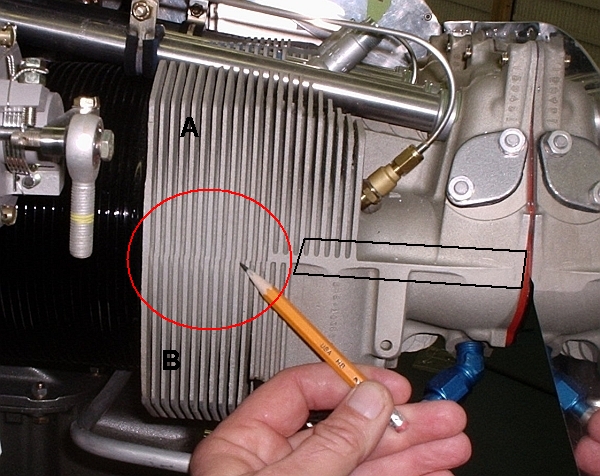

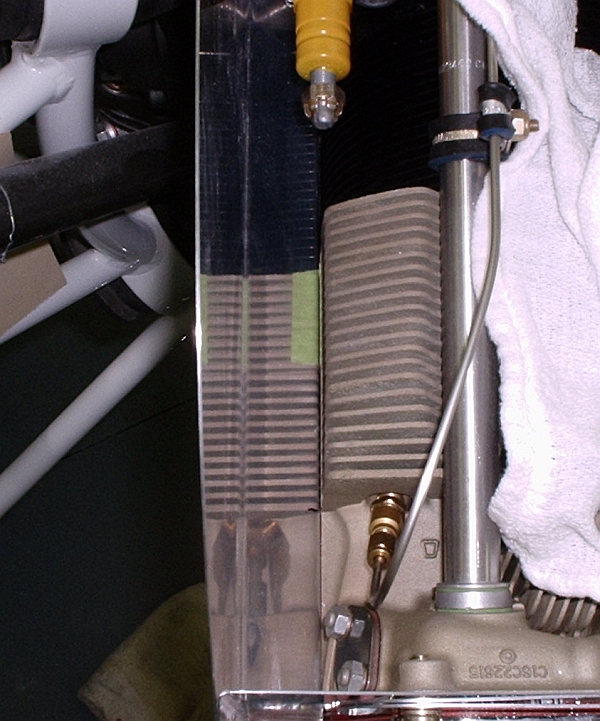

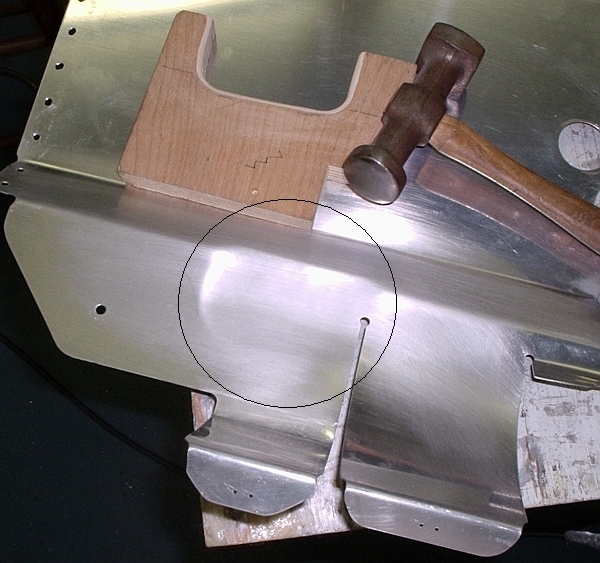

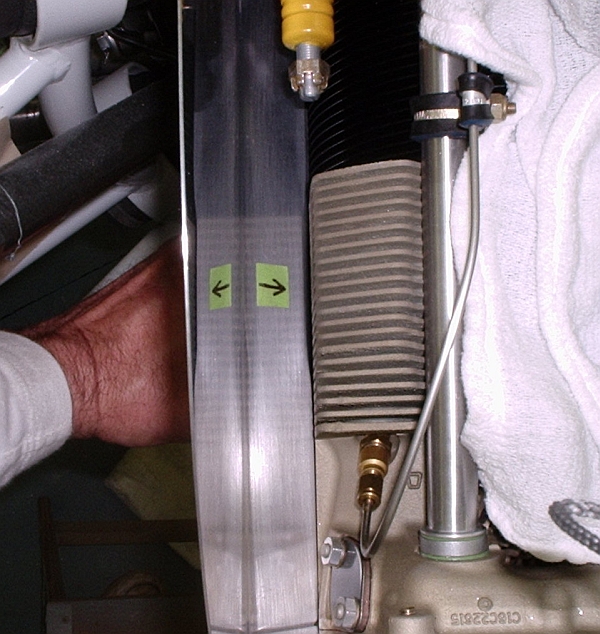

Like you I'm tempted to try full wraps. I have hesitated because of economics, not lack of curiosity; IO390 cylinders are very expensive. I've mostly concentrated on extreme sealing and a bit of airflow control to the regions left lacking. I do have partial wraps on the barrels between cylinders, thus each cylinder has symmetrical airflow.

Some of the EZ bunch have done radical cooling experiments. You might look there.