The rest of the story. Previously I wrote:

Ok, the 50016-08 acro mounts are now installed, and I got an opportunity to get in three hours today over to Baton Rouge and back.

Initial impression: Vibration transmission is acceptable, but different. Previously it was smoothest around 2400~2450. Now it's glass smooth at 2700, acceptable at 2450, and shakes the glareshield at 2350 and below.

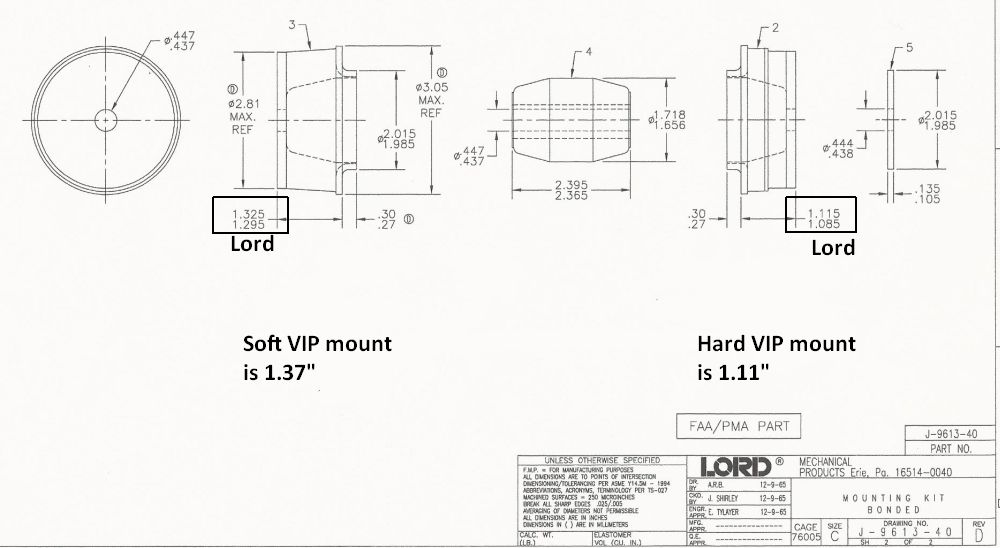

There are two possible explanations, maybe more. It was dynamically balanced recently, but the Lord mounts were sagging enough to have internal contact, so that may have skewed the balance process. It feels like it needs balancing, but I know that human perception is a very poor gauge. The other possibility is perhaps more likely. Short version is that I've raised the system's natural frequency, so it's now closer to the disturbing frequency, increasing transmissibility. Isolation gets better as the ratio of Fd/Fn is increased, and I've decreased the ratio.

I'll get another balance and we'll see. More later.

The answer seems to be ....

both.

With the VIP acro mounts, the airframe shake below 2400

felt like an out of balance prop. Vic had done a dynamic balance not long ago, before I discovered dripping silicone, and realized how far gone my Lord mounts really were. With new VIP acro mounts installed, we were both curious about how failed Lord mounts might affect the dynamic balance process. If one or more gel bags and center spacers were against the inner steel ring, would it skew the dynamic balance results?

Answer...apparently yes. I flew over to Fresh Fried Chicken where Vic and I repeated the balance done just a few months ago. Getting down to 0.01 required the removal of a #10 screw, washer, and compact nut installed when we balanced with bad mounts. IPS immediately dropped below 0.04 (or maybe it was 0.03). A washer or two in the right place dropped it to 0.01. The lesson, now learned, is obvious; check your mounts before balance.

However, when flying home, there was no significant difference in cockpit feel. Pulling the prop to down to around 2300 would still make my sunglasses dance. Ok, fine. If it ain't balance, it must be resonance.

As previously noted, the VIP acro mounts are simply two thin isolators and a slightly different internal bushing length. I called VIP, and they were willing to sell me the thick isolators and the correct bushings, since I already had plenty of thin isolators. The resulting thick-thin set is exactly what you would get from Vans or Aircraft Spruce. Blocked out the day Saturday and got 'em in there.

Drum roll please; a short test flight yesterday confirmed the return of good vibes. It's been a long time since I had

new Lord mounts, so a direct comparison is hard to judge. There is no

objectionable behavior with the VIP mounts; I can pull RPM down with fairly high MP and the previous large amplitude shake is gone. I did notice one difference between the VIP and Lord mounts. With the Lords, I recall pulling 3G would cause a noticeable change in engine sound and feel. There does not seem to be any change with the VIP mounts. I assume G would push the Lord gel bags into contact with the rings. I do not know how long ago I noticed the sound change with G; could be after they had sagged a little.

I'll fly the new isolators a while and eyeball them for sag. Given this is a return to the "one size fits all" isolator set, I'm interested to see if the large engine actually does shorten isolator life. Seems logical that a 320 would not load the isolators as much as a 390.

For those who wish to know more, there is a nice tutorial regarding isolation and transmissibility in the Lord isolator catalog:

https://www.lord.com/sites/default/files/compressed_PC6116_AerospaceandDefenseIsolatorCatalog.pdf