ExErcoupeGuy

I'm New Here

Before Further Flight?

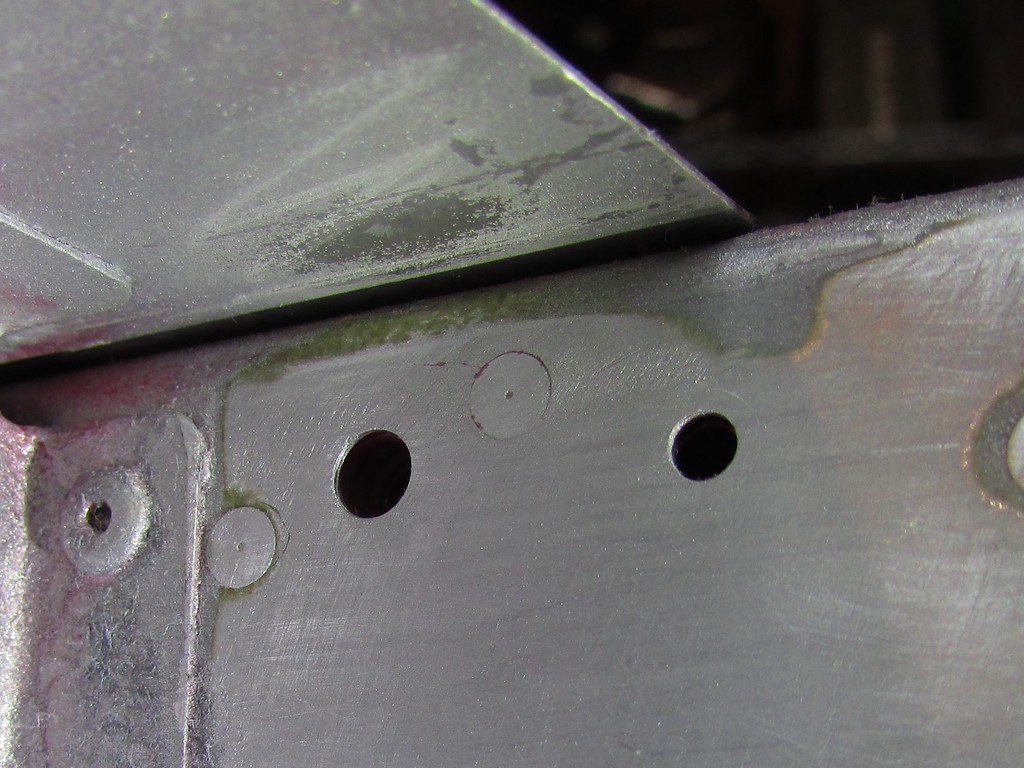

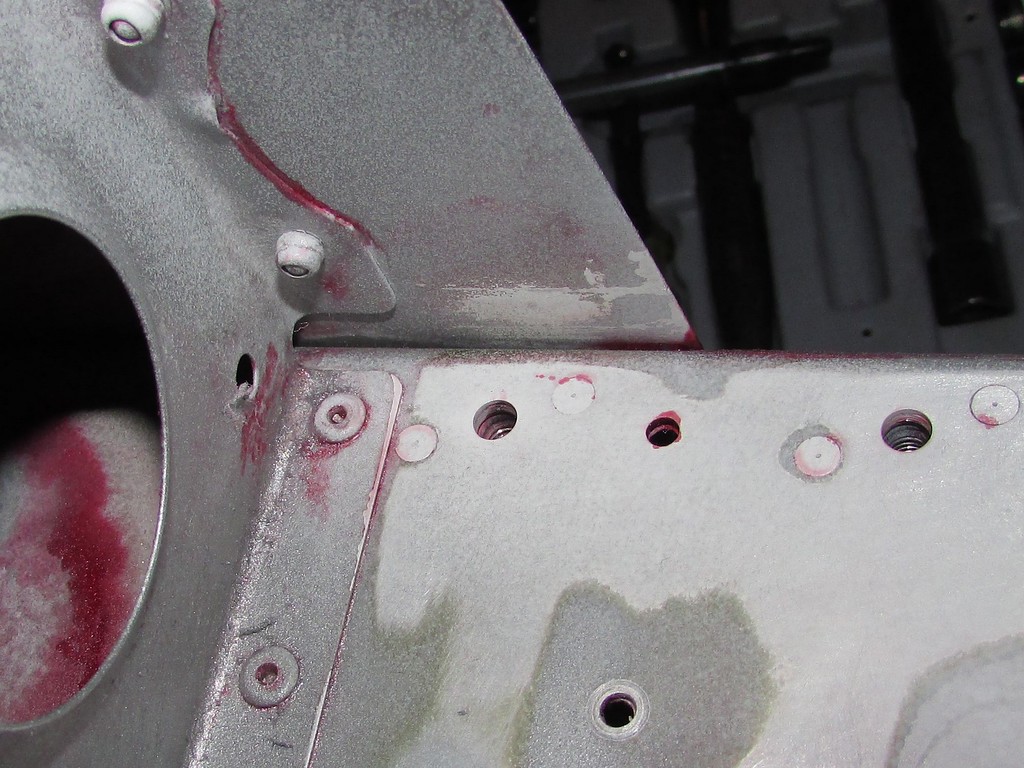

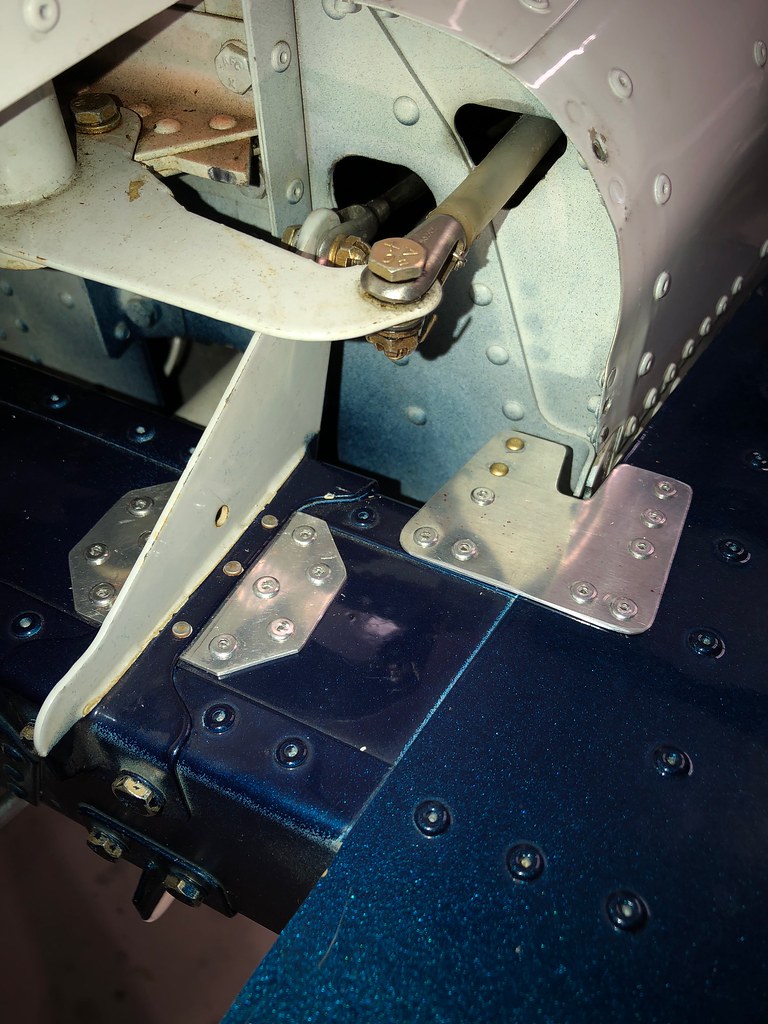

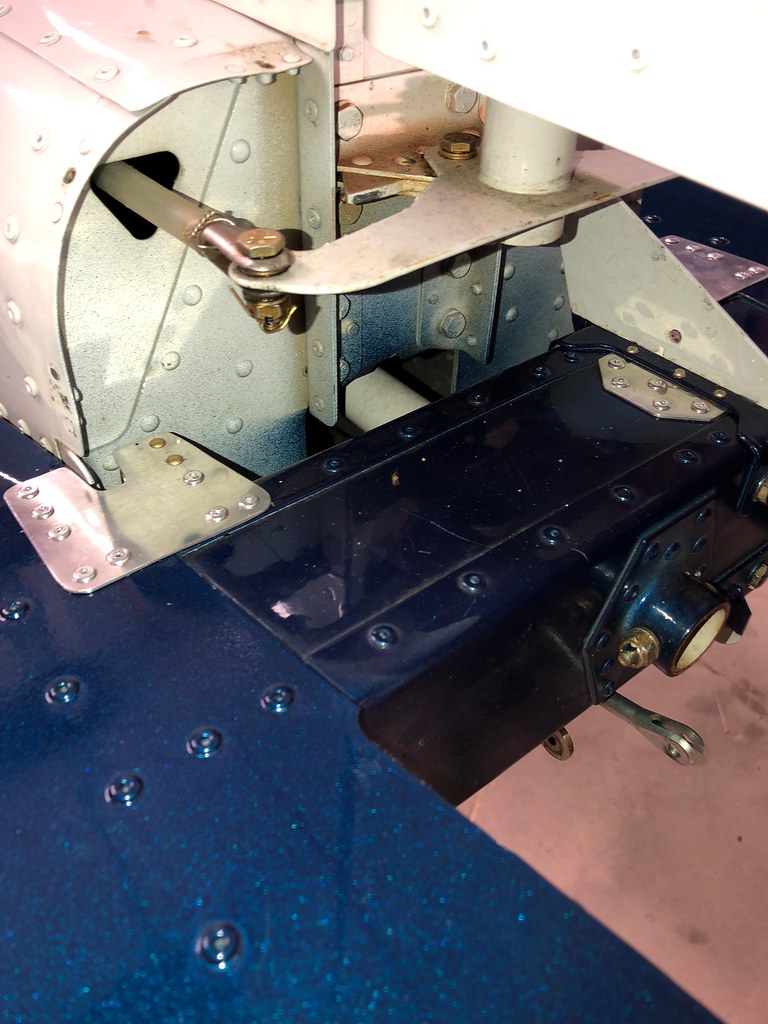

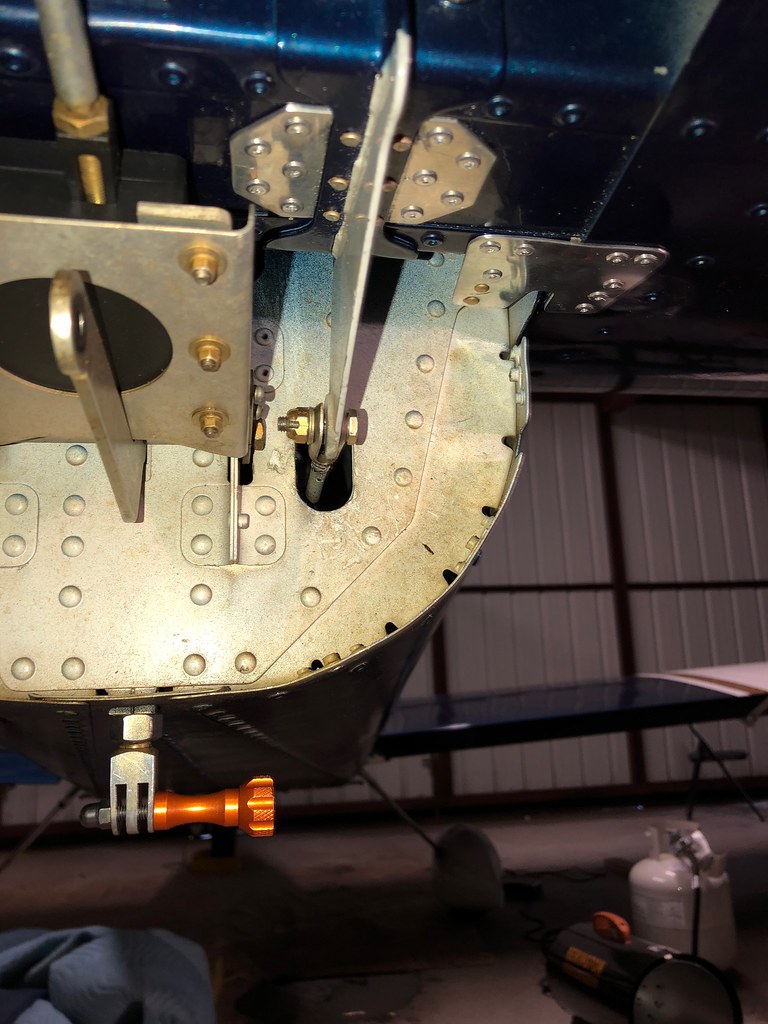

My RV 12 is here in Marco Island for the month, far from its home base in Marysville, OH and my Rotax/RV12 qualified shop in Delaware, OH. I concur as to some confusion in the wording of SB 10-02-02 (in no small measure owing to my lack of builder/repair skills). In particular it takes some effort to determine where the ?inspection? for cracks begins and ends, and where the ?fix? begins. This post raises a good question on the scope of the inspection ? is it required to fully remove the stabilator and spar brackets before conducting the inspection, or is it sufficient to bore scope, magnaflux or penetrant dye the spar area with just the tail cone fairings removed? I am very fortunate to have a master mechanic willing to do whatever is required, including fabricating the new parts and installing the full fix. But, it would be much more efficient if an inspection could be done short of removing the stabilator assembly. Because if no cracks are found, we can button up the fairings and fly until next annual/100 hours. I guess the bottom line issue is ? can the SB be read to permit a compliant inspection without removing the stabilator? Given the SB?s admonition about the potential difficulty in discovering any cracks, would this be safe in any event? My RV was built and flew the end of 2013, and has now 200 hours; always hangared. Thank you for any advice.

My RV 12 is here in Marco Island for the month, far from its home base in Marysville, OH and my Rotax/RV12 qualified shop in Delaware, OH. I concur as to some confusion in the wording of SB 10-02-02 (in no small measure owing to my lack of builder/repair skills). In particular it takes some effort to determine where the ?inspection? for cracks begins and ends, and where the ?fix? begins. This post raises a good question on the scope of the inspection ? is it required to fully remove the stabilator and spar brackets before conducting the inspection, or is it sufficient to bore scope, magnaflux or penetrant dye the spar area with just the tail cone fairings removed? I am very fortunate to have a master mechanic willing to do whatever is required, including fabricating the new parts and installing the full fix. But, it would be much more efficient if an inspection could be done short of removing the stabilator assembly. Because if no cracks are found, we can button up the fairings and fly until next annual/100 hours. I guess the bottom line issue is ? can the SB be read to permit a compliant inspection without removing the stabilator? Given the SB?s admonition about the potential difficulty in discovering any cracks, would this be safe in any event? My RV was built and flew the end of 2013, and has now 200 hours; always hangared. Thank you for any advice.