Draker

Well Known Member

Merry Christmas everyone!

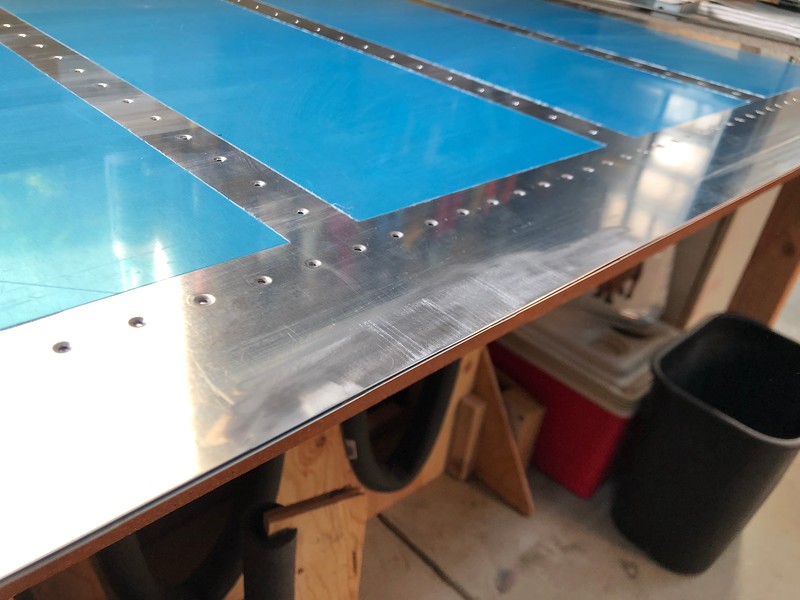

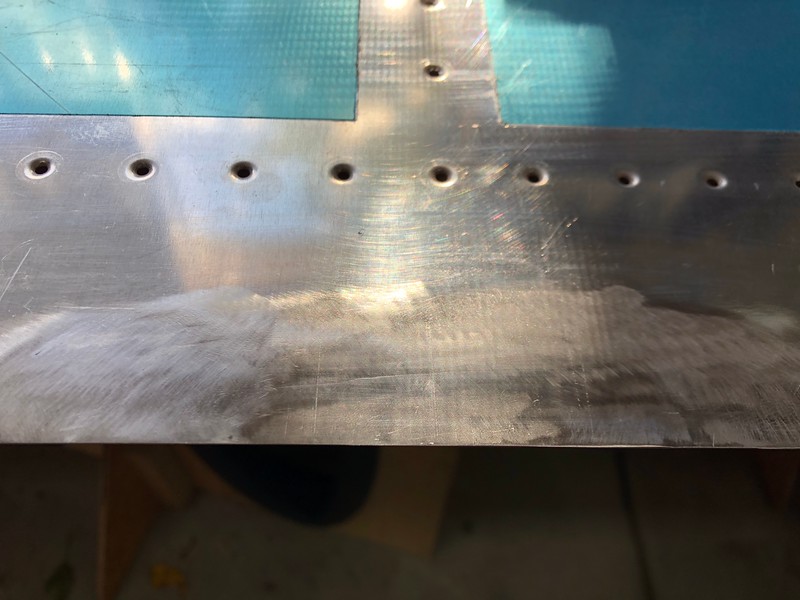

Some days it seems like it's disaster after disaster on the RV-7 project. Today's one of those discouraging days. After a mishap with the deburring wheel, I'm left with a pretty badly bent wing skin:

This is the trailing edge of my top right inboard W-702 skin, after a great deal of re-straightening on my part. Maximum deflection in the center of the bend is approx. 1/4 inch. Looking ahead in the plans, it looks like this section overlaps the flap, and there are no rivets going in here that could "aid" in its straightening. The fit against the flap looks pretty tight, so this would probably end up rubbing against that control surface. I'm afraid it looks like I'll need to be ordering a new skin, but before I do, I thought I'd ask if anyone has any good repair ideas.

Best wishes, VAF!

Some days it seems like it's disaster after disaster on the RV-7 project. Today's one of those discouraging days. After a mishap with the deburring wheel, I'm left with a pretty badly bent wing skin:

This is the trailing edge of my top right inboard W-702 skin, after a great deal of re-straightening on my part. Maximum deflection in the center of the bend is approx. 1/4 inch. Looking ahead in the plans, it looks like this section overlaps the flap, and there are no rivets going in here that could "aid" in its straightening. The fit against the flap looks pretty tight, so this would probably end up rubbing against that control surface. I'm afraid it looks like I'll need to be ordering a new skin, but before I do, I thought I'd ask if anyone has any good repair ideas.

Best wishes, VAF!

Last edited: