David Paule

Well Known Member

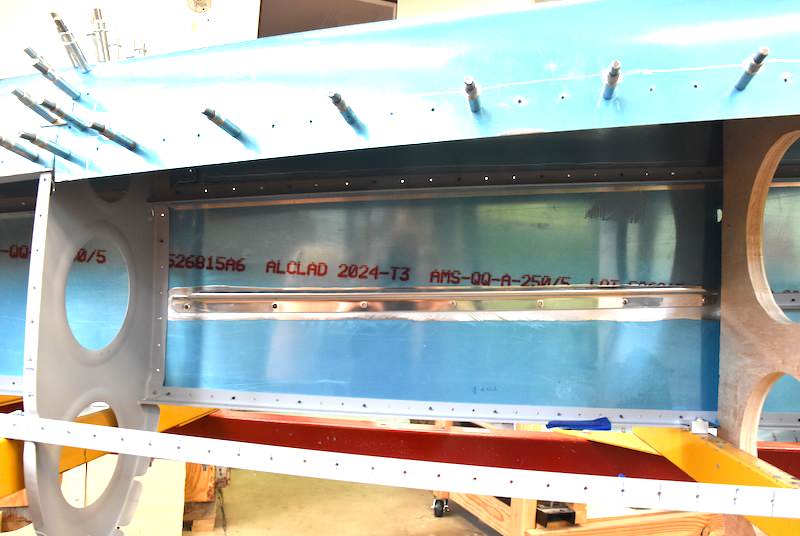

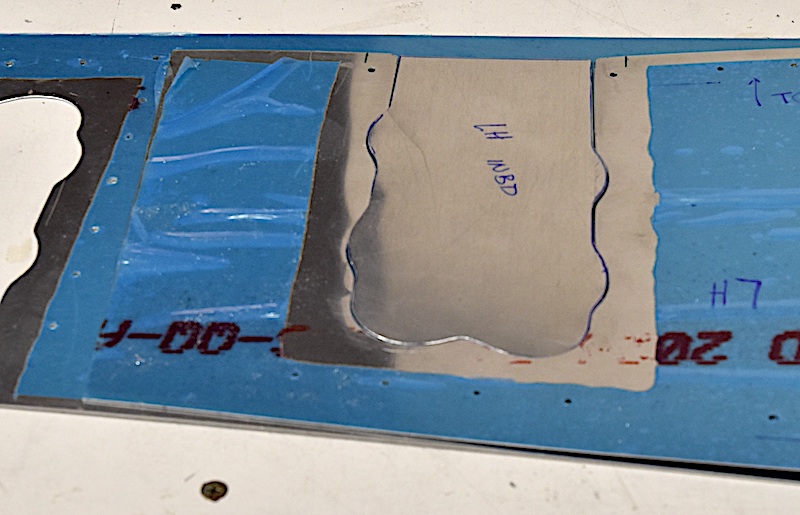

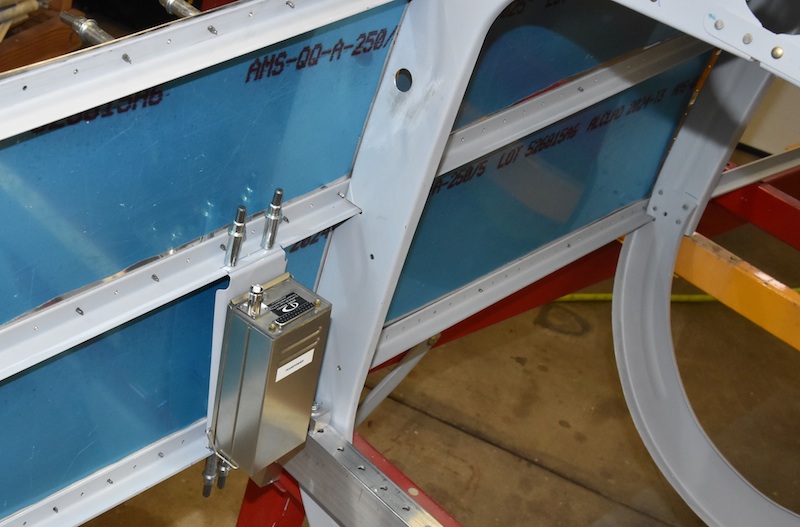

I've been getting the smaller details completed. The gussets at the forward (middle of the image) ends of the baggage compartment ribs that are on the far right needed to be riveted to the seat baggage bulkhead. Here I've got the left one clecoed and am using a .063 plate to ensure that the right one is fair to the seat bulkhead while I drilled the flange.

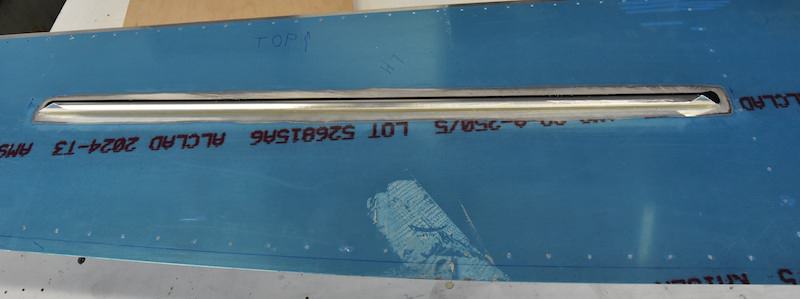

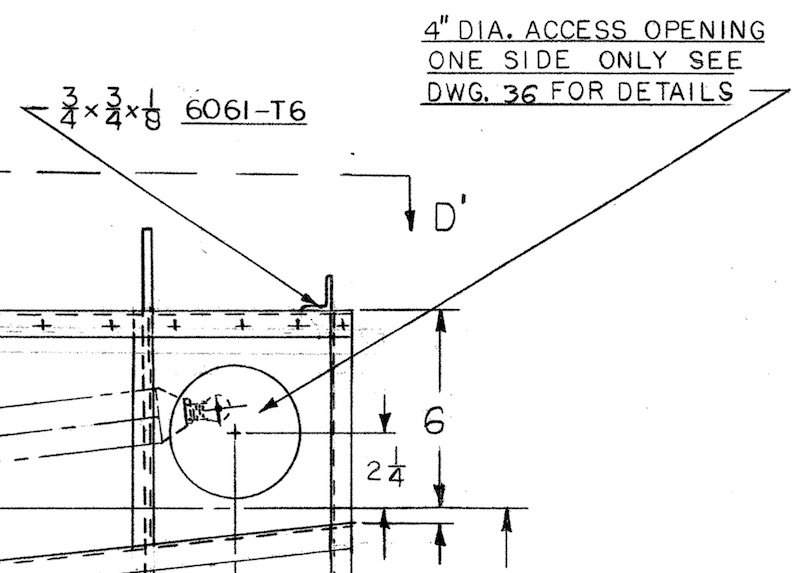

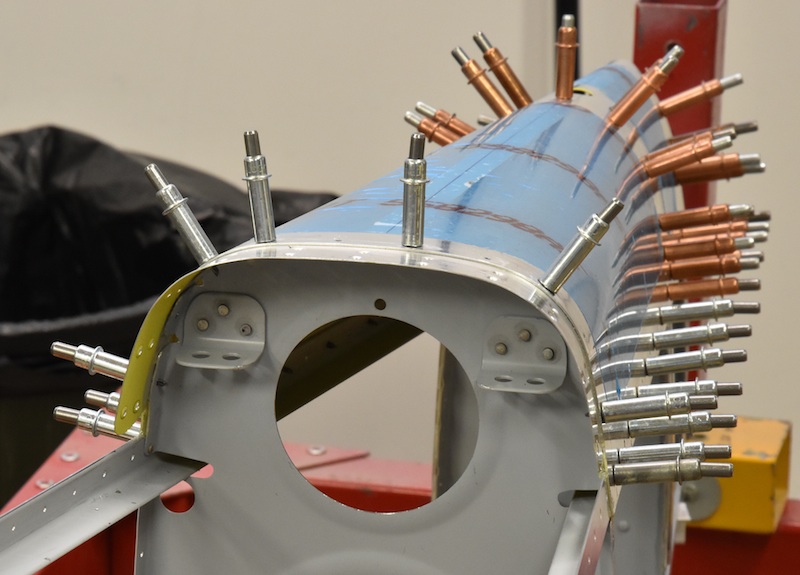

I worked my way aft, bulkhead by bulkhead, deburring and priming parts. The aft-most two bulkheads, F-310 and F-311 make an assembly with the tailspring mount. They'd been lined up and clecoed. I drilled them out to 1/4" and installed temporary bolts. Then I removed it and put it on the table for its portrait.

Later, I disassembled and primed the parts. They are now reinstalled.

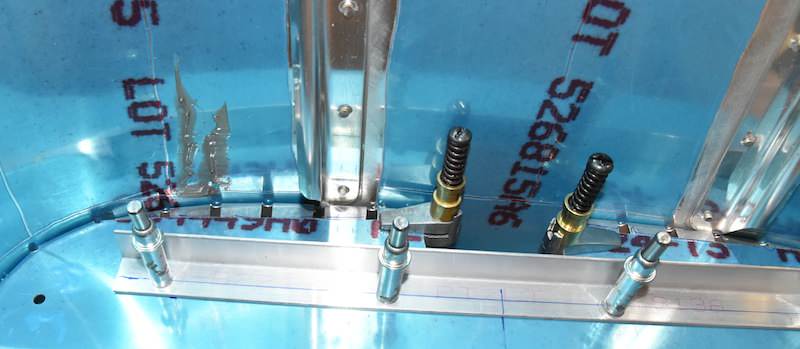

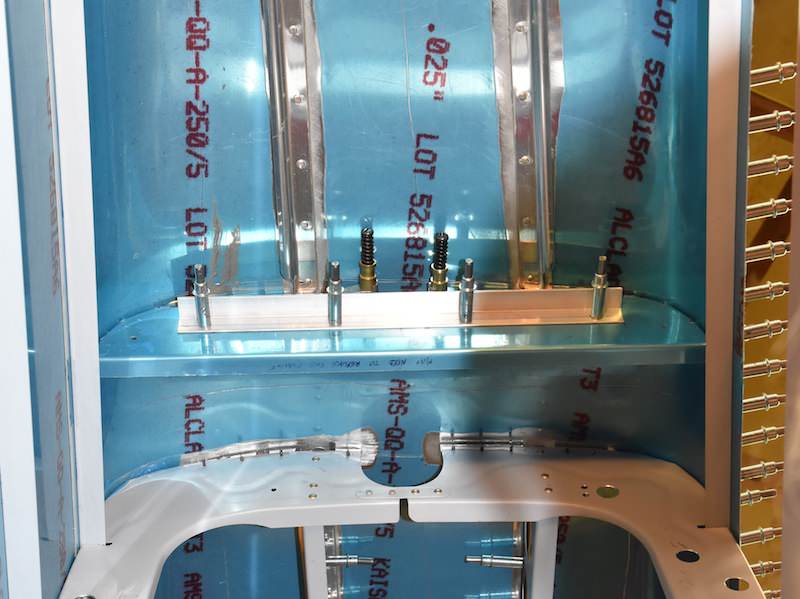

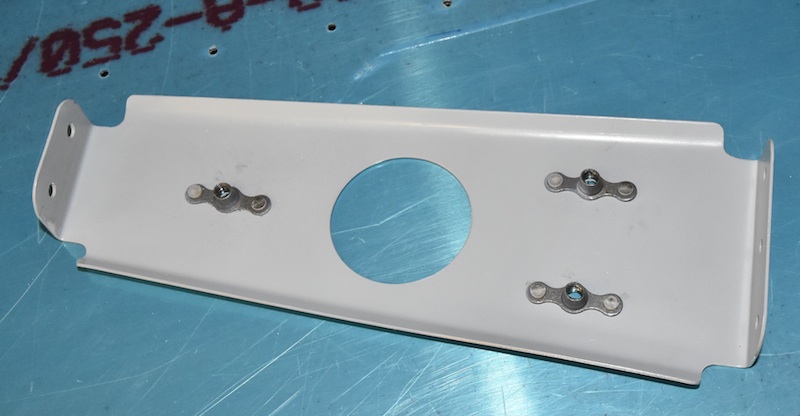

At that point, I removed the top longerons for deburring and priming. These support the fuselage frame on the Fry jig. After they got detailed, I reinstalled them and clecoed it all together. Before checking the overall rig of the fuselage, I decided to recheck the trueness of the Fry jig itself. In the photo I've got the SmartTool digital level showing that the jig is level crosswise. This is looking up (the fuselage is upside down) and aft from the firewall through the forward tunnel area.

The jig is good to 0.1 degrees, which is nice but not great. In a couple cases one direction of the level would show 0.1 degrees and the other direction would show 0.0. I figured that in these cases the angle was about 0.05 degrees. There were two diagonal corners that were slightly out of alignment out of the six total adjustment screws. Two of them, two that didn't need adjustment, can be seen in the photo. It wasn't hard to figure out that I could straighten the jig in roll with only one screw, if the out-of-true were small, without changing the pitch level in any measurable way. After a short bit of work, the jig was again true.

My garage floor is built upon a moving clay base. It's not surprising that the floor shifted. At least that's my hypothesis for the Fry jig going slightly out of true.

The photos are also hosted here, here and here.

Dave

I worked my way aft, bulkhead by bulkhead, deburring and priming parts. The aft-most two bulkheads, F-310 and F-311 make an assembly with the tailspring mount. They'd been lined up and clecoed. I drilled them out to 1/4" and installed temporary bolts. Then I removed it and put it on the table for its portrait.

Later, I disassembled and primed the parts. They are now reinstalled.

At that point, I removed the top longerons for deburring and priming. These support the fuselage frame on the Fry jig. After they got detailed, I reinstalled them and clecoed it all together. Before checking the overall rig of the fuselage, I decided to recheck the trueness of the Fry jig itself. In the photo I've got the SmartTool digital level showing that the jig is level crosswise. This is looking up (the fuselage is upside down) and aft from the firewall through the forward tunnel area.

The jig is good to 0.1 degrees, which is nice but not great. In a couple cases one direction of the level would show 0.1 degrees and the other direction would show 0.0. I figured that in these cases the angle was about 0.05 degrees. There were two diagonal corners that were slightly out of alignment out of the six total adjustment screws. Two of them, two that didn't need adjustment, can be seen in the photo. It wasn't hard to figure out that I could straighten the jig in roll with only one screw, if the out-of-true were small, without changing the pitch level in any measurable way. After a short bit of work, the jig was again true.

My garage floor is built upon a moving clay base. It's not surprising that the floor shifted. At least that's my hypothesis for the Fry jig going slightly out of true.

The photos are also hosted here, here and here.

Dave